Torque Converter Failure in ZF Transmissions: Diagnosis, Causes, and Sourcing Reliable Replacement Units

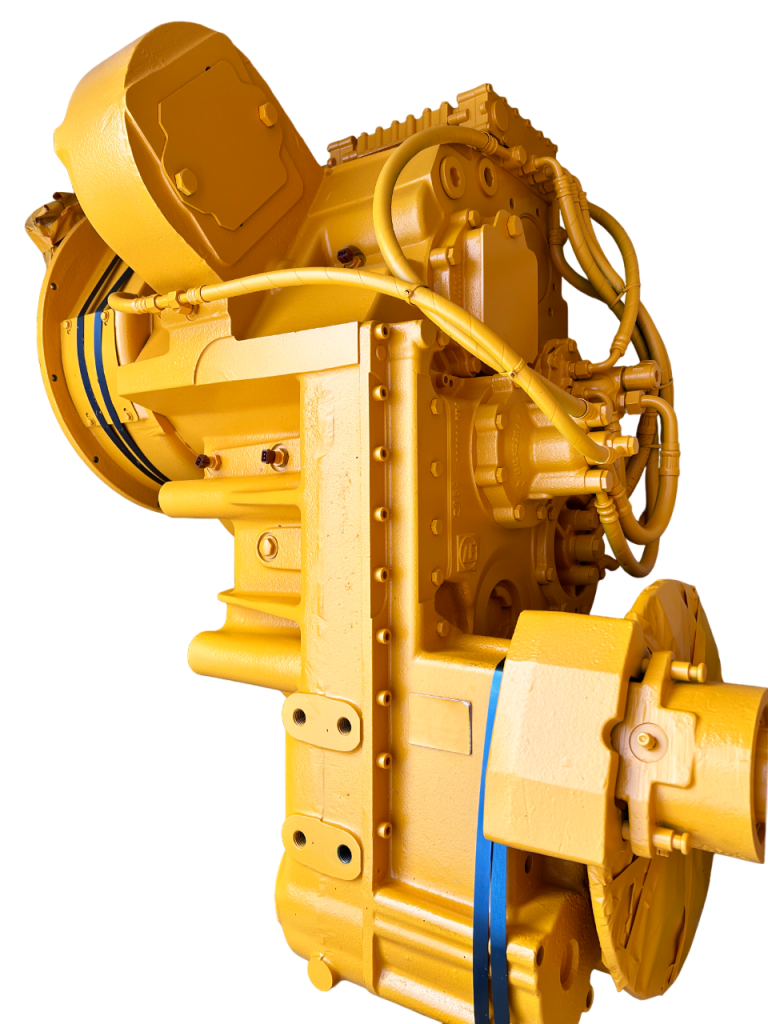

Introduction: The Power Transfer Bridge

The torque converter is the essential hydraulic coupling between the engine and the ZF transmission. Its failure directly leads to catastrophic power loss, excessive heat generation, and low hydraulic pressure. Diagnosing a faulty converter is vital for avoiding unnecessary transmission overhauls.

This guide, informed by Tianjin XiaoHang Construction Machinery Co., Ltd.’s 20 years of expertise, provides a clear diagnostic pathway for torque converter failure and outlines the key considerations for sourcing high-quality replacement units.

Section 1: Telltale Symptoms of Torque Converter Failure

Recognizing the Signs Before Total Breakdown

Symptoms often include: 1. Overheating: A failing lock-up clutch generates excessive slip and heat. 2. Contaminated Fluid: Internal failure sheds metal debris into the hydraulic system. 3. Poor Acceleration/Stall Speed: The machine performs poorly, indicating low transfer efficiency.

Section 2: Procurement Strategy for Torque Converters

Quality and Compatibility are Non-Negotiable

Torque converters are complex assemblies. Sourcing requires strict adherence to the BOM number as the stalling speed and lock-up parameters are application-specific.

XiaoHang Technical Insight: Our 20 years of experience ensures we supply torque converters that are fully balanced and engineered to meet the exact stall specifications of your ZF model, preventing recurrence of overheating and slippage. We guarantee fast lead times for these critical, high-value components.

Conclusion: Secure Your Power Transfer

Do not risk machine performance with a substandard replacement. Partner with XiaoHang Machinery Co. to source reliable torque converters, protected by our technical support and competitive pricing.

Why Using the Wrong Transmission Fluid Kills Your ZF: Specifications, Consequences, and Sourcing Approved Alternatives

Substandard fluid directly contributes to major mechanical faults: 1. Seal Deterioration: Incorrect chemical composition attacks seal materials, leading to internal pressure leaks and slippage. 2. Clutch Pack Contamination: Poor quality oil lacks the thermal stability to protect friction plates, leading to rapid material degradation.

XiaoHang Technical Insight: Our 20 years of repair data confirm that low-quality fluid is often the hidden cause behind recurring solenoid and sensor failures, as contaminants are not suspended or filtered properly.

Section 3: Sourcing Reliable Fluid and Filter Kits

The XiaoHang Solution for Fluid and Filter Procurement

Tianjin XiaoHang Construction Machinery Co., Ltd. offers a complete solution:

- Verified Compatibility: We supply high-quality, ZF-compatible fluids and comprehensive filter kits that are technically approved by our experts.

- Fast Lead Times & Cost Advantage: Leveraging our China supply chain, we ensure fast lead times and competitive pricing for all fluid and filter packages.

Conclusion: Protect Your Investment with Verified Fluids

Ensure the longevity of your ZF transmissions by prioritizing technically compliant fluids and high-flow filters. Contact XiaoHang Machinery Co. today to secure verified fluid and filter kits, backed by our technical guarantee.

The Essential Role of Oil and Lubricant Specifications

Title: Why Using the Wrong Transmission Fluid Kills Your ZF: Specifications, Consequences, and Sourcing Approved Alternatives

Introduction: The Unsung Hero of Transmission Life

The fluid inside a ZF transmission is more than just oil; it is a highly engineered component responsible for lubrication, cooling, and hydraulic actuation. Using an incorrect or substandard fluid can instantly void warranties and lead to catastrophic component failure. For global procurement managers, the challenge is sourcing approved fluids or high-quality alternatives that maintain the required viscosity and thermal stability.

This guide, backed by Tianjin XiaoHang Construction Machinery Co., Ltd.’s 20 years of expertise, details the crucial specifications for ZF transmission fluid and offers reliable procurement strategies.

Section 1: Understanding ZF Fluid Specifications

The Difference Between Approved and Compliant Fluids

ZF transmissions demand fluids that meet specific performance standards. These standards dictate the viscosity index, shear stability, and anti-wear additives. Using non-approved fluids can cause excessive heat generation, foaming, and premature friction plate wear. Always verify the fluid specification against the transmission model’s Bill of Material (BOM) number.

Section 2: The Immediate Consequences of Using Substandard Fluid

When the Wrong Oil Goes Wrong

Substandard fluid directly contributes to major mechanical faults: 1. Seal Deterioration: Incorrect chemical composition attacks seal materials, leading to internal pressure leaks and slippage. 2. Clutch Pack Contamination: Poor quality oil lacks the thermal stability to protect friction plates, leading to rapid material degradation.

XiaoHang Technical Insight: Our 20 years of repair data confirm that low-quality fluid is often the hidden cause behind recurring solenoid and sensor failures, as contaminants are not suspended or filtered properly.

Section 3: Sourcing Reliable Fluid and Filter Kits

The XiaoHang Solution for Fluid and Filter Procurement

Tianjin XiaoHang Construction Machinery Co., Ltd. offers a complete solution:

- Verified Compatibility: We supply high-quality, ZF-compatible fluids and comprehensive filter kits that are technically approved by our experts.

- Fast Lead Times & Cost Advantage: Leveraging our China supply chain, we ensure fast lead times and competitive pricing for all fluid and filter packages.

Conclusion: Protect Your Investment with Verified Fluids

Ensure the longevity of your ZF transmissions by prioritizing technically compliant fluids and high-flow filters. Contact XiaoHang Machinery Co. today to secure verified fluid and filter kits, backed by our technical guarantee.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

Mitigating ZF Parts Supply Chain Delays

Mitigating ZF Parts Supply Chain Delays: How to Secure Fast Lead Times and Competitive Pricing from China

Introduction: The Global Procurement Challenge

Global distributors are constantly seeking reliable alternatives to overcome supply chain volatility. This strategic guide from Tianjin XiaoHang Construction Machinery Co., Ltd. outlines how to leverage the specialized capabilities of suppliers in China.

Section 1: The Hidden Costs of Long Lead Times

- Operational Risk: Long lead times force distributors to carry excessive inventory or face significant customer penalties.

- The XiaoHang Solution: Our strategic focus allows us to maintain a robust, ready-to-ship inventory for common failure parts, guaranteeing fast lead times.

Section 2: Leveraging the China Supply Chain Advantage

- Cost Efficiency Through Infrastructure: We provide high-quality spares at a highly competitive price point.

- Quality Control Informed by Experience: Our 20 years of repair and field experience ensures we stock only parts verified as reliable.

Section 3: XiaoHang’s Integrated Risk Mitigation Strategy

- Technical Support for Procurement Assurance: Our technical team helps you verify complex part numbers and compatibility issues upfront, eliminating errors.

- Inventory Transparency: We provide clear communication on stock levels for critical high-wear parts.

Conclusion: The Partnership for Speed and Savings

Tianjin XiaoHang Construction Machinery Co., Ltd. offers the solution: 20 years of technical authority integrated with the fast lead times and competitive pricing of the Chinese supply chain.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

Troubleshooting ZF 4WG200 Slippage

Why is My ZF 4WG200 Shifting Slowly or Slipping? Diagnosis, Causes, and Parts Solutions

Introduction: Addressing Critical Transmission Slippage

When the ZF 4WG200 experiences slow shifting or clutch slippage, it signals imminent mechanical failure. This expert guide, leveraging the 20 years of repair and supply expertise from Tianjin XiaoHang Construction Machinery Co., Ltd., details the causes and highlights the verified parts needed for a permanent fix.

Section 1: Initial Diagnosis – Distinguishing Slippage from Electronic Faults

- The Key Indicator: Low Control Pressure: Slippage occurs when clutch pack contact force is too low, often stemming from inadequate control pressure.

- Electronic Faults Mimicking Slippage: Malfunctioning Proportional Solenoid Valves (PSV) or Speed Sensors can cause shifting delays that feel like slippage.

Section 2: Mechanical Causes – Worn Parts that Require Replacement

- Worn Clutch Plates and Steel Discs: This is the most common mechanical failure, accelerated by high heat. Replacement parts must be of high quality.

- Damage from Contaminated Oil: Contamination necessitates a full inspection of all seals, gaskets, and filters. A full overhaul kit is often required.

Section 3: The XiaoHang Machinery Co. Advantage in Critical Sourcing

- Reliable Quality, Competitive Pricing: We supply high-specification ZF replacement parts (including friction clutches, steel discs, and solenoid valves) that are proven in the rigorous Chinese construction sector.

- Unbeatable Supply Chain Speed: Our China-based supply chain ensures fast lead times and minimizes customer downtime.

- Expert Technical Support: Every component purchase is backed by our dedicated technical support team composed of 20-year industry experts.

Conclusion: Eliminate Slippage. Guarantee Performance.

Partner with Tianjin XiaoHang Construction Machinery Co., Ltd. to gain the decisive advantage of speed and technical authority.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

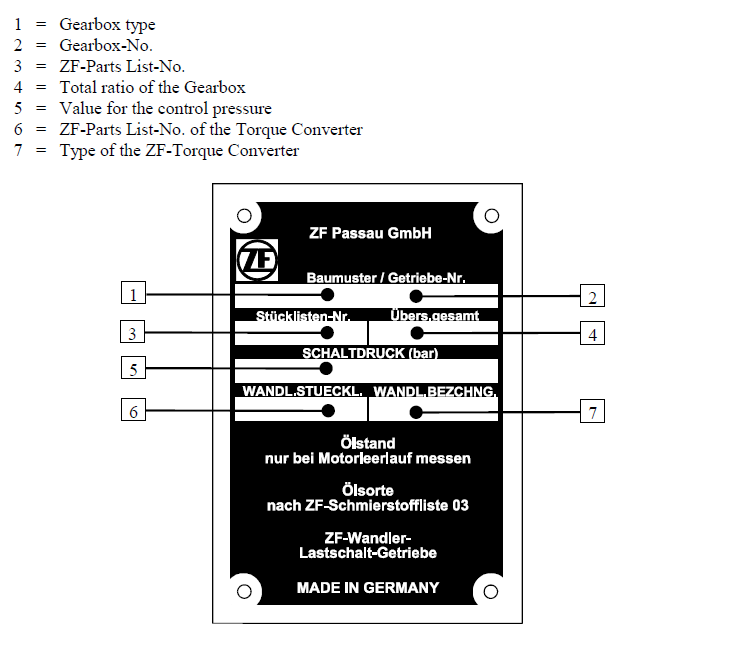

The Ultimate Guide to Identifying Your Specific ZF Transmission Model Plate (e.g., WG200 vs WG210)

Introduction: Eliminating Uncertainty in ZF Transmission Parts Procurement

Accurate identification of the ZF transmission model is the cornerstone of correct parts procurement. Confusing similar models—such as the WG200 and WG210—can lead to severe compatibility issues. This guide, brought to you by Tianjin XiaoHang Construction Machinery Co., Ltd., provides a definitive, step-by-step method for decoding the ZF model plate.

Section 1: Locating and Understanding the ZF Model Identification Plate

The model plate is the single most important document. It provides the Type Designation (e.g., 4WG200), the Serial Number, and the Bill of Material (BOM) number.

- Essential Data: The BOM number is critical, as it defines the exact parts configuration. Always visually confirm the data plate on the actual transmission.

Section 2: Deciphering Common Confusion: WG200 vs. WG210

Subtle differences between common models often cause the most significant procurement errors.

- Key Differences Affecting Part Compatibility: These models often differ in clutch pack configuration, torque converter sizing, and input/output flange types. Major internal overhaul kits are usually specific.

- The Procurement Risk: Ordering the wrong internal kit can halt the repair. XiaoHang Machinery Co.’s 20 years of technical expertise helps you navigate these subtle internal differences.

Section 3: The Role of the Serial Number and BOM in Sourcing

- Why the BOM Number is More Important: The BOM number specifies the particular version built for a specific machine manufacturer (OEM) or application. Always provide your supplier with the full Type Designation and the BOM number to ensure a precise match.

- The XiaoHang Guarantee: XiaoHang Machinery Co.’s access to extensive Chinese OEM parts data allows us to swiftly cross-reference these specific BOM numbers to the correct spare parts.

Conclusion: Procurement Confidence Starts with Accuracy

Partnering with a supplier who possesses both deep technical knowledge and rapid supply chain capabilities, like Tianjin XiaoHang Construction Machinery Co., Ltd., is essential.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

Cross-Referencing Genuine ZF Part Numbers

H1: The Definitive Guide to Cross-Referencing Genuine ZF Part Numbers for Reliable Aftermarket Alternatives

Introduction: Secure Your Supply Chain with Verified ZF Expertise

For global distributors and procurement managers, securing a reliable and cost-effective supply of ZF transmission parts is paramount. The risk of ordering an incorrect part number—and the ensuing costly machine downtime—is simply too high. The solution lies in accurate cross-referencing, a process that demands deep technical knowledge and a trustworthy supply partner.

This guide provides a professional, systematic methodology, backed by two decades of industry authority from Tianjin XiaoHang Construction Machinery Co., Ltd. As one of China’s most established off-highway transmission solution providers, XiaoHang Machinery Co. combines technical rigor with the logistical advantages of China’s supply chain to ensure you source the right part, every time.

Section 1: Why Accurate Cross-Referencing is Your Procurement Insurance

Errors in part number identification, particularly with complex ZF components, lead directly to losses. For overseas distributors, this damages client relationships and your brand’s reputation for reliability.

- The Cost of Inaccurate Sourcing: A failed part match due to poor cross-referencing quickly erodes customer trust and causes prolonged machine downtime.

- The XiaoHang Solution: As a leading specialist in ZF, Liuzhou ZF, and Advance transmissions for 20 years, XiaoHang Machinery Co. leverages extensive field knowledge to verify compatibility before components are shipped. When you buy from XiaoHang Machinery Co., you purchase with technical certainty.

Section 2: Deciphering the ZF Part Number: A Technical Checklist

The structured ZF part number is the key to accurate sourcing. Understanding its logic prevents costly errors, especially when transitioning to high-quality aftermarket options.

- Three Steps to Technical Verification: Always confirm the complete model number (e.g., 4WG200, 6WG310) from the machine’s plate, and use the leading digits to verify the component category.

- Cross-Reference with Certified Expertise: Relying on generic databases is risky. Partnering with a specialized supplier like XiaoHang Machinery Co. provides access to proprietary, field-tested verification processes. XiaoHang Machinery Co. provides unparalleled technical support to verify complex part numbers.

Section 3: The XiaoHang Advantage: Unbeatable Lead Times, Cost-Efficiency, and Quality

1. Supply Chain Security and Competitive Pricing: XiaoHang Machinery Co.’s strategic position within China’s robust manufacturing infrastructure allows us to maintain an extensive, ready-to-ship inventory. This ensures fast lead times and enables us to pass on cost benefits, resulting in highly competitive pricing.

2. Technical Authority and Post-Sale Support: We are a 20-year veteran of the repair and service field. Every purchase is backed by our dedicated technical support team composed of 20-year industry experts. This technical backing is your guarantee of success.

Conclusion: Partner with XiaoHang Machinery Co. for Procurement Excellence

Successful ZF parts sourcing requires a reliable partner who offers technical depth and logistical superiority. Tianjin XiaoHang Construction Machinery Co., Ltd. provides the ideal solution.

Introduction: The Core of Transmission Performance

The clutch pack—a critical assembly of friction plates and steel discs—is the beating heart of any ZF power shift transmission. When these components fail due to wear, the result is costly machine downtime, slow shifting, and eventual complete transmission failure. For global distributors and procurement managers, accurate diagnosis of clutch pack wear and sourcing high-quality, durable replacement kits is a priority.

This ultimate guide, utilizing the 20 years of repair and supply expertise from Tianjin XiaoHang Construction Machinery Co., Ltd., details the telltale signs of clutch pack failure and highlights the procurement strategies necessary for a successful overhaul. We connect you with verified solutions, backed by our technical authority and efficient Chinese supply chain.

Section 1: Identifying Clutch Pack Wear – The Diagnosis Checklist

Identifying clutch pack wear before catastrophic failure requires attention to performance metrics and operational symptoms.

1. Performance Symptoms Indicating Slippage

The most common signs of clutch pack failure relate directly to power transfer:

- Delayed or Slow Shifting: The time required for the gear to engage lengthens, indicating reduced hydraulic pressure effectiveness.

- Engine RPM Flaring: The engine speed increases significantly upon shifting without a corresponding increase in wheel speed, clearly showing slippage.

- Excessive Heat: As discussed in our previous guide, slippage generates intense friction, leading to transmission overheating and accelerated material breakdown.

2. Physical Diagnosis After Disassembly

Upon disassembly, technicians should look for: Darkened or burnt friction material (a sign of overheating), warped steel discs (caused by uneven heat distribution), and excessive clearance within the clutch pack assembly (indicating material loss).

Section 2: The Critical Choice: Sourcing High-Quality Clutch Kits

The quality of the replacement clutch kit determines the success and longevity of the overhaul. Substituting low-grade friction material for a cost saving is a false economy.

1. Focus on Material Composition

High-performance aftermarket friction plates must withstand extreme temperatures and pressure cycles common in heavy machinery. Look for plates featuring high-heat-resistant material compounds that maintain a stable coefficient of friction even under thermal stress.

2. The Importance of Complete Kits

A reliable supplier provides complete overhaul solutions, including:

- Friction Plates: (The clutch material)

- Steel Discs: (To dissipate heat and provide a smooth contact surface)

- Seals and Gaskets: Necessary for maintaining crucial internal hydraulic pressures.

XiaoHang Machinery Co. Advantage: Leveraging our 20 years of repair and field expertise, we ensure our ZF-compatible clutch kits are sourced and assembled with superior material compounds, engineered to endure the harshest working conditions and provide longer operational life than many standard replacements.

Section 3: XiaoHang Machinery Co. – Your Partner in High-Value Procurement

Sourcing major components like clutch kits requires absolute confidence in your supplier’s technical knowledge and delivery speed.

1. Technical Certainty and Support

- 20 Years of Expertise: We don’t just sell parts; we provide solutions backed by two decades of experience in off-highway transmission service. Every clutch kit purchase from Tianjin XiaoHang Construction Machinery Co., Ltd. includes access to our dedicated technical support team.

- Repair-Informed Inventory: Our inventory selection (including high-wear parts for WG200, WG310, and BP series) is guided by what our service technicians have verified as reliable in the field, eliminating procurement risk for you.

2. Unmatched Supply Chain Efficiency

- Fast Lead Times & Inventory: Our strategic position within China’s robust manufacturing infrastructure allows us to maintain strong inventory and guarantee fast lead times. For critical components like clutch kits, this speed is vital to minimize customer downtime.

- Competitive Costing: We provide high-quality clutch and overhaul kits at a highly competitive price point, ensuring you can offer superior value to your clients while maintaining healthy margins.

Conclusion: Invest in Performance. Trust the Experts.

Successfully addressing ZF clutch pack wear requires precise component selection and rapid supply. By partnering with Tianjin XiaoHang Construction Machinery Co., Ltd., you gain a supplier that guarantees both technical quality and logistical speed.

Need Immediate Technical Support or Clutch Kit Quotes?

Contact our International Sales Team today.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

Don’t compromise on the heart of the transmission. Contact Tony Chang today to secure high-performance clutch kits and technical certainty.

Introduction: The Small Part with the Biggest Impact

In the world of heavy-duty transmissions, no component is more critical to long-term health than the filter. A seemingly small part, the ZF transmission filter is responsible for capturing microscopic contaminants that cause up to 75% of internal wear. For global distributors and procurement managers, the twin threats of model mismatch and counterfeit products pose enormous risks to machinery reliability.

This authoritative guide, backed by the 20-year technical expertise of Tianjin XiaoHang Construction Machinery Co., Ltd., provides the essential checklist for accurate ZF filter sourcing. We will show you how to verify genuine quality and ensure optimal flow rates, all while leveraging the competitive pricing and speed of our trusted Chinese supply chain.

Section 1: The Three Risks of Filter Procurement

Sourcing incorrect or low-quality filters can lead directly to catastrophic transmission failure. You must be aware of the following dangers:

1. Flow Restriction and Pressure Loss (The Internal Killer)

A poor-quality filter often uses inferior media or an incorrect design, leading to excessive resistance. This restriction starves the oil pump, resulting in low control pressure—the leading cause of clutch slippage and overheating. Optimal flow rate, not just filtration rating, is non-negotiable.

2. Model Mismatch (The Common Error)

ZF uses different filters across models (e.g., 4WG200 vs. 6WG310) and even within the same model depending on the Bill of Material (BOM) number. An incorrect filter may physically fit but fail to maintain the required internal bypass pressure, compromising system protection.

3. Counterfeit Products (The Costly Deception)

The market is flooded with counterfeit ZF filters. These products often use substandard paper media that degrades rapidly, shedding particles directly into the hydraulic system. They lack proper internal seals and may collapse under normal operating pressure.

Section 2: XiaoHang’s Strategy: How to Select and Verify Genuine Quality

To protect your inventory and your customer’s equipment, follow this technical verification process endorsed by Tianjin XiaoHang Construction Machinery Co., Ltd.:

1. Model-Specific Verification:

- Always Cross-Reference the BOM: Never rely solely on the Type Designation (e.g., 4WG200). Provide your supplier with the full 10-digit ZF Part Number (which includes the specific BOM code) to ensure a 100% match.

- The Physical Check: High-quality filters have a precise fit, uniform pleating, and durable casing. Genuine-quality internal bypass valves are correctly calibrated—a key feature often missing in counterfeits.

2. Counterfeit Detection Guidance:

- Packaging Scrutiny: Authentic packaging features high-resolution printing, proper security holograms (if applicable), and correctly spelled details. Counterfeit boxes often use thin cardboard and blurry graphics.

- The Supplier Audit: The single best defense is partnering with a supplier of proven repute. XiaoHang Machinery Co. has been a trusted supplier in the market for 20 years, guaranteeing the source integrity of the ZF-compatible filters we provide. We stand by the quality of our filter media and flow performance.

Section 3: The Procurement Advantage of Partnering with XiaoHang

Securing high-quality filters requires a supplier that prioritizes technical integrity over the lowest price. XiaoHang Machinery Co. offers this balance:

1. Inventory and Logistics Mastery

- Fast Lead Times: Our China-based supply chain ensures we maintain a ready and extensive inventory of the most popular ZF filters, allowing for rapid dispatch and minimal delay in your logistics chain.

- Cost Efficiency: We provide competitively priced, verified-quality filters, allowing you to maximize profitability without risking quality compromises.

2. Technical Backing on Every Order

- Every filter order is backed by the technical authority of our 20-year experienced team. We ensure your order is cross-referenced correctly against the machine’s specific application. If your technician has doubts about a filter’s suitability, our experts provide the immediate technical support needed for verification. We guarantee the compatibility and flow performance of every filter we supply.

Conclusion: Do Not Compromise on Filter Quality

A ZF transmission filter is a long-term investment in machinery uptime. Avoid the risk of counterfeit products and model mismatches by partnering with a technically reliable supplier. Tianjin XiaoHang Construction Machinery Co., Ltd. offers you the assurance of genuine quality, accurate selection, and competitive supply speed.

Need Immediate Technical Support or Filter Quotes?

Contact our International Sales Team today.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

ZF Ecomat Series: Key Maintenanc Parts and Service Kit Contents for Long Service Life

Introduction: Mastering Ecomat Maintenance for Urban Reliability

The ZF Ecomat series—commonly found in city buses, airport equipment, and specialized urban vehicles—demands meticulous, scheduled maintenance to ensure maximum uptime and reliability. For distributors and fleet managers, successfully managing the Ecomat lifecycle hinges on securing the correct maintenance kits and high-quality, long-lasting spare parts.

This professional guide, informed by Tianjin XiaoHang Construction Machinery Co., Ltd.’s 20 years of transmission expertise, breaks down the essential maintenance checklist and key part solutions for the Ecomat series. We connect our technical authority with the competitive advantages of our Chinese supply chain to offer you a superior maintenance solution.

Section 1: The Ecomat Maintenance Imperative: Beyond the Oil Change

While regular fluid and filter changes are fundamental, the Ecomat series requires careful attention to specific components vulnerable to urban operational stress.

1. Critical Components in Every Service Interval

The service interval for an Ecomat transmission demands the replacement of components that prevent system contamination and fluid breakdown:

- Transmission Filters: Both main and suction filters must be replaced to prevent internal blockages that can starve the oil pump. Using non-genuine or low-quality filters is a common cause of premature solenoid failure.

- Gaskets and Sealing Rings: The integrity of the sealing system is vital for maintaining correct internal pressure and preventing external leakage, especially around the oil pan and pump housing.

2. Scheduled Replacement of Wear Parts

Components like solenoid valves and speed sensors should be considered high-value wear items in a proactive maintenance plan, especially in high-mileage urban fleets. Proactive replacement prevents unexpected breakdown and costly towing.

Section 2: What Must Be Included in a Reliable Ecomat Service Kit?

For procurement managers sourcing service kits, precision is paramount. A comprehensive kit must include every necessary item, verified against the specific Ecomat version (e.g., Ecomat 1, 2, or 4).

Key Kit Contents Checklist:

- Main and Suction Filters: Always verify the correct mesh size and flow rate specifications.

- Oil Pan Gaskets: Should be high-temperature resistant and chemically compatible with ZF transmission fluids.

- Sealing Rings & O-Rings: A full set of critical external and internal seals.

- Technical Bulletin/Service Instructions: Supplied by a reliable source to ensure correct installation.

XiaoHang Machinery Co. Advantage: Leveraging our 20 years of repair experience, we assemble Ecomat Service Kits that are field-proven. Our kits contain only high-specification components, ensuring your technicians have everything needed for a successful maintenance stop, minimizing repeat visits.

Section 3: The XiaoHang Advantage: The Technical and Supply Chain Edge

When securing Ecomat spares globally, XiaoHang Machinery Co. offers a unique combination of technical depth and logistical superiority.

1. Supply Chain Security and Competitive Pricing

- Fast Lead Times: XiaoHang Machinery Co.’s strategic position within China’s manufacturing infrastructure ensures we hold an extensive, ready-to-ship inventory of Ecomat maintenance kits and high-value solenoid parts. This minimizes your customer’s vehicle downtime.

- Cost Efficiency: We pass on the efficiency benefits of our supply chain, providing high-quality, reliable spares at a highly competitive price point, securing better margins for your distribution business.

2. 20 Years of Technical Authority Backing

As a 20-year veteran of transmission repair and service, Tianjin XiaoHang Construction Machinery Co., Ltd. offers more than just parts:

- Proactive Technical Support: Every Ecomat service kit purchase includes access to our dedicated technical support team. Our experts can assist your technicians with Ecomat-specific diagnostics or fluid specifications, ensuring proper maintenance procedures are followed. This technical expertise guarantees the longevity of the repair.

Conclusion: Optimize Reliability with XiaoHang Ecomat Solutions

For distributors and managers running urban fleets, scheduled maintenance is non-negotiable. Partner with Tianjin XiaoHang Construction Machinery Co., Ltd. to gain the speed and cost benefits of the Chinese supply chain, combined with the 20 years of field-tested technical authority needed to secure a reliable, high-performance maintenance program.

Need Immediate Technical Support or Service Kits?

Contact our International Sales Team today.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |