ZF 4 BP 230 TCU 6073.024.056 Sourcing: Ensuring Software Compatibility and Electronic Integrity

Introduction: The Electronic Brain

The TCU (Transmission Control Unit) is the electronic brain of the ZF 4 BP 230. The control unit for the BP EC4A system is material number 6073.024.056. Sourcing a replacement TCU is complex as it requires both the hardware and the correct integrated software.

This highly technical guide from Tianjin XiaoHang Construction Machinery Co., Ltd. focuses on the specialized procurement of the TCU and essential electronic components.

Section 1: The Criticality of Software Compatibility

Hardware vs. Software Match

The replacement TCU 6073.024.056 must come “complete with software” pre-loaded to match the specific application of the machine. An unmatched TCU will cause shifting errors or place the machine in Limp Home Mode.

Section 2: Associated Electronic Components

Sourcing Beyond the Main Control Unit

Effective TCU replacement requires a check of supporting electronic components, including:

- Gaskets and Seals: For the control unit housing (e.g., 0501.339.370).

- Cabling: External and internal cables (e.g., CABLE WORKING MACHINE 4681.160.001).

Section 3: XiaoHang Technical Authority on Electronics

Eliminating Electronic Procurement Risk

Our 20 years of expertise includes extensive experience with EC4a and related electronic systems. XiaoHang Machinery Co. guarantees the software compatibility and technical integrity of the TCU units we supply, ensuring a true plug-and-play solution. We offer fast lead times on these high-value, sensitive electronic parts.

Conclusion: Precision Electronic Sourcing

Trust Tianjin XiaoHang Construction Machinery Co., Ltd.’s technical authority for critical ZF electronic components like the TCU 6073.024.056.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| 5858518@gmail.com | |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

Expanding Service Scope: Sourcing ZF Axle and Driveline Components for Enhanced Customer Retention

Introduction: Beyond the Transmission

For high-value customer retention, distributors must offer comprehensive driveline solutions. Many machines utilizing the ZF 4 BP 230 transmission also feature integrated ZF axle and driveline components, creating a perfect opportunity to expand your parts inventory and service scope.

This guide from Tianjin XiaoHang Construction Machinery Co., Ltd. helps you strategically expand your offerings to include high-demand ZF axle spares, maximizing customer value.

Section 1: Key ZF Axle Components for Off-Highway

High-Wear Driveline Parts Checklist

Common ZF axle service needs include:

- Differential Components: Gears, shims, and sealing rings for differential assemblies.

- Final Drive Assemblies: Planetary gears and axle shafts.

- Brake Components: High-performance wet brake discs and seals (where applicable).

Section 2: Sourcing Strategy for High-Load Axle Parts

Load Rating and Material Verification

Axle parts must meet specific load ratings. XiaoHang Machinery Co.’s 20 years of experience ensures the axle components we supply meet the rigorous durability required for heavy construction applications. We focus on parts that guarantee long-term performance under stress.

Section 3: The Advantage of Unified Driveline Sourcing

One Supplier for Transmission and Axle

XiaoHang Machinery Co. offers a unified sourcing solution. This simplifies procurement, as you can source both ZF 4 BP 230 transmission repair kits and essential ZF axle spares from a single, reliable source. Our fast lead times and competitive pricing apply across the entire driveline portfolio.

Conclusion: Maximize Retention with Full Driveline Service

Expand your service offerings. Contact XiaoHang Machinery Co. today to secure verified ZF axle and driveline components at competitive prices, backed by our technical authority.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| 5858518@gmail.com | |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

Critical Spares for the ZF 4 BP 230 SHIFT SYSTEM: Solenoids, Sensors, and the Duct Plate

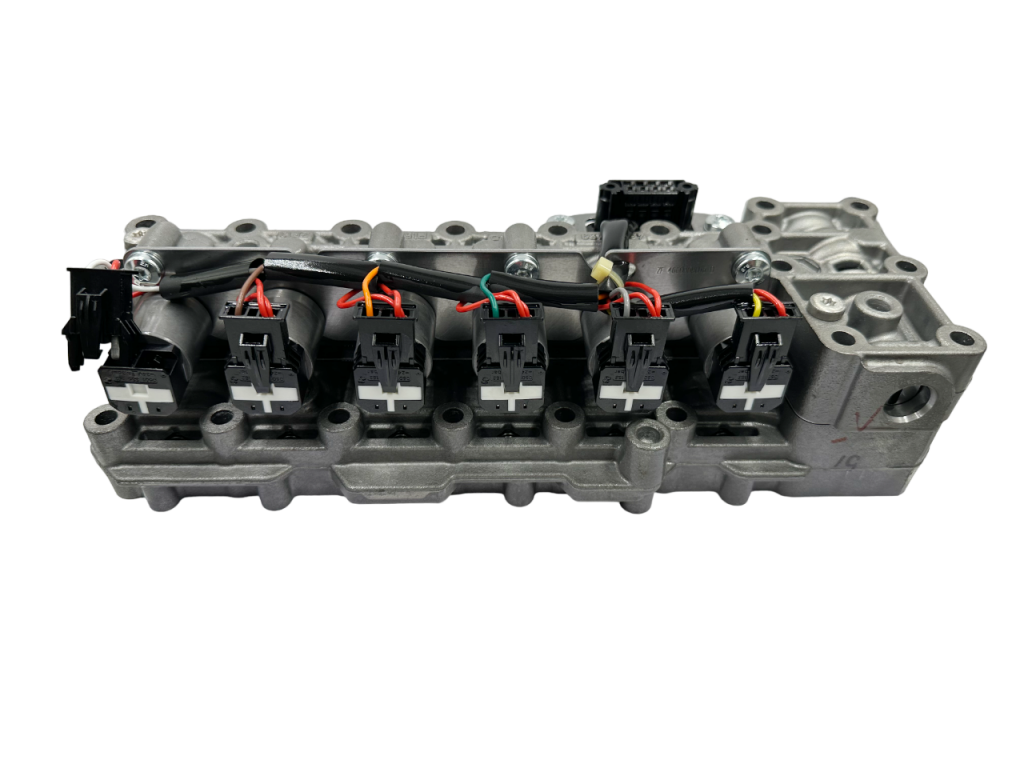

Introduction: The Shift System’s Nerve Center

The SHIFT SYSTEM (Assembly 4681.106.005) contains the Hydraulic Control Unit (HCU) and the critical electronic and sealing components that manage gear engagement. Failures here often result in erratic shifting or total drive loss.

This guide focuses on the procurement of high-precision components for the SHIFT SYSTEM, including the Temperature Sensor 0501.322.532 and various screw plugs and O-rings.

Section 1: Key Components for SHIFT SYSTEM Integrity

Precision Parts Checklist

The SHIFT SYSTEM is protected by various seals and contains critical electronic sensors. Key parts include:

- GASKET 4681.306.010 and DUCT PLATE 4681.306.011: Essential for hydraulic circuit integrity.

- TEMPERATURE SENSOR 0501.322.532: Provides vital oil temperature data to the TCU.

- SCREW PLUGS 4475.280.016 and O-RINGS: Used for sealing and pressure test points.

Section 2: Sourcing Sensors and Sealing Assurance

The XiaoHang Technical Guarantee

Electronic components like the Temperature Sensor 0501.322.532 must be verified for compatibility. Our 20 years of expertise guarantees accurate cross-referencing. For sealing, we supply all necessary O-rings (e.g., 11X2 and 13X2) to maintain the required hydraulic pressure.

Section 3: Fast Supply for Complex Assemblies

XiaoHang Machinery Co. minimizes downtime on complex shift system repairs. We leverage our China supply chain for fast lead times and competitive pricing on both major components (like the valve block) and all necessary sealing kits.

Conclusion: Ensure Shift Precision with XiaoHang

For verified ZF 4 BP 230 SHIFT SYSTEM spares, trust the technical precision and supply speed of Tianjin XiaoHang Construction Machinery Co., Ltd.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| 5858518@gmail.com | |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

ZF 4 BP 230 Pressure Oil Pump 4681.122.001: Diagnosis, Causes of Failure, and Sourcing Verified Units

Introduction: The Source of Hydraulic Pressure

The Pressure Oil Pump (Material-assembly-group-no: 4681.122.001) is the hydraulic heart of the ZF 4 BP 230 transmission. Its primary role is to supply pressurized oil to the clutch packs (at 16+2 bar) and the lubrication circuit. Pump failure instantly causes system pressure loss, leading to slippage and overheating.

This guide from Tianjin XiaoHang Construction Machinery Co., Ltd. focuses on diagnosing oil pump failure and procuring a reliable replacement unit.

Section 1: Recognizing Oil Pump Failure

Diagnosis for Pressure Loss

Failure of the Gear Pump 0750.109.325 often results in low or inconsistent pressure readings across all clutch test ports. Common causes include:

- Contamination: Metal debris from internal wear damages the pump gears and housing.

- Cavitation: Caused by low fluid levels or restricted suction filters.

Section 2: Procuring the Pressure Oil Pump

Ensuring Flow and Pressure Integrity

Replacement pumps (Assembly 4681.122.001) must guarantee the correct flow rate and pressure delivery. XiaoHang Machinery Co. supplies only verified pumps, emphasizing the quality of the internal GEAR PUMP 0750.109.325 and the surrounding O-rings (e.g., 182X3) to prevent leakage.

Section 3: Technical Support for Pump Replacement

The XiaoHang Assurance

Replacing the oil pump is a complex, high-stakes repair. Our 20 years of repair expertise ensures we provide the necessary technical support. Our fast lead times and strong inventory minimize machine downtime for this critical repair.

Conclusion: Restore Hydraulic Power with XiaoHang

For verified ZF 4 BP 230 Pressure Oil Pumps (Assembly 4681.122.001), trust the technical precision and reliable supply from Tianjin XiaoHang Construction Machinery Co., Ltd.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| 5858518@gmail.com | |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

Introduction: Protecting Rotational Integrity

Bearings are crucial to the ZF 4 BP 230’s performance, maintaining rotational alignment and minimizing friction. Failure of a single TAPER ROLLER BEARING can lead to catastrophic damage to the input, output, and intermediate shafts. The input shaft assembly (Material-assembly-group-no: 4681.102.001) alone requires specific taper roller bearings.

This specialized guide from Tianjin XiaoHang Construction Machinery Co., Ltd. details the procurement of high-precision ZF taper roller bearings like 0735.372.296 and 0735.372.300.

Section 1: Essential Bearings and Their Locations

Input Shaft Assembly Requirements

The Input Shaft assembly 4681.102.001 requires two identical TAPER ROLLER BEARINGS, Part No. 0735.372.296, size 60,000X95,000X27,000. The output shaft assembly 4681.103.002 requires two TAPERED ROLLER BEARINGS, Part No. 0735.372.297.

Section 2: Sourcing for Precision and Durability

Tolerance and Material Specification

Bearings are precision components; their tolerance and material hardness must withstand high load and temperature. XiaoHang Machinery Co. supplies only high-grade taper roller bearings that meet strict dimensional and load specifications.

Section 3: Technical Support for Bearing Installation

Avoiding Installation Errors

Proper installation, including setting correct preload, is vital for bearing life. Our 20 years of repair expertise ensures we provide the technical support necessary for accurate installation, guaranteeing the longevity of the repair. We maintain a strong inventory of all critical bearing part numbers.

Conclusion: Ensure Alignment with XiaoHang Bearings

For precise ZF 4 BP 230 taper roller bearings (Part Nos. 0735.372.296, 0735.372.300 etc.), rely on Tianjin XiaoHang Construction Machinery Co., Ltd.’s technical authority.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| 5858518@gmail.com | |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

Introduction: Critical Clutches K2 and K3

The K2 and K3 clutches in the ZF 4 BP 230 transmission are fundamental for engaging 2nd and 3rd forward and reverse gears. High operational stress makes the K2 and K3 clutch packs susceptible to wear. The required repair kit for these crucial couplings is 4681.298.015.

This procurement guide from Tianjin XiaoHang Construction Machinery Co., Ltd. focuses on sourcing the K2/K3 Repair Kit 4681.298.015 and ensuring quality control for these vital components.

Section 1: K2 and K3 Clutch Engagement

The Role in Speed and Direction

The K2 clutch is essential for 2nd gear (KV/K2 forward, KR/K2 reverse), and K3 is used for 3rd gear (KV/K3 forward, KR/K3 reverse) and also 4th gear (K4/K3 forward). Their failure directly compromises machine usability. The nominal pressure for these clutch packs is 16+2 bar.

Section 2: Sourcing Complete and Verified Repair Kits

The Material Number 4681.298.015

The repair kit material number 4681.298.015 covers the repair of these high-duty components. XiaoHang Machinery Co.’s 20 years of repair expertise ensures our supplied kits include:

- Verified Friction Discs: Engineered for high thermal stability.

- Complete Sealing Elements: Including O-rings (e.g., 64X3 and 120X3 for the piston) to guarantee optimal hydraulic engagement pressure.

Section 3: Fast Supply for Multi-Clutch Repairs

Mitigating Downtime on Overhauls

Overhauling K2 and K3 requires numerous specialized parts. XiaoHang Machinery Co. utilizes its efficient Chinese supply chain to offer fast lead times and competitive pricing on the complete 4681.298.015 repair kit, minimizing the total repair cycle time.

Conclusion: Guarantee 2nd and 3rd Gear Performance

For the ZF 4 BP 230 K2/K3 Repair Kit 4681.298.015, rely on the technical authority and quick supply of Tianjin XiaoHang Construction Machinery Co., Ltd.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| 5858518@gmail.com | |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

Introduction: The K1 Clutch Pack

The K1 clutch is one of the essential speed clutches in the ZF 4 BP 230 transmission. Its function is critical for engaging 1st gear forward (KV/K1) and 1st gear reverse (KR/K1). Wear or failure necessitates a complete overhaul using the designated REPAIR KIT 4681.298.014.

This guide from Tianjin XiaoHang Construction Machinery Co., Ltd. details the procurement of the K1 Repair Kit and the critical components it includes.

Section 1: Components of the K1 Coupling Repair Kit 4681.298.014

Overhaul Essentials for K1

The clutch repair kit (Material number: 4681.298.014) for Coupling K1 is essential for restoring the functionality of this gear speed clutch. Key items in the clutch assembly (Assembly group no: 4681.171.002) include:

- Inner Clutch Disks 0501.316.591: Quantity 9.

- Outer Clutch Disks 0501.212.373: Quantity 2.

- End Shim 0501.340.819: For setting clutch clearance.

Section 2: Sourcing for Clutch Durability

The XiaoHang Performance Guarantee

The longevity of the K1 repair depends entirely on the quality of the friction and steel discs. Our 20 years of repair expertise ensures our supplied kits contain high-specification friction material that guarantees reliable engagement pressures (typically 16+2 bar for the system pressure valve).

Section 3: Technical Support for Overhaul Success

Reducing Installation Errors

Installing clutch repair kits, including the K1 Repair Kit 4681.298.014, requires precise knowledge of clutch clearance settings. XiaoHang Machinery Co. provides technical support to your technicians, leveraging our 20 years of repair experience to ensure correct installation, a vital service that prevents repeat failure.

Conclusion: Restore 1st Gear Reliability

Secure your ZF 4 BP 230 K1 Repair Kit 4681.298.014 from the trusted technical partner, Tianjin XiaoHang Construction Machinery Co., Ltd.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| 5858518@gmail.com | |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

Introduction: The Power Inside China’s Biggest Brands

Major international OEMs, including China’s largest manufacturers like Liugong and XCMG, rely on ZF transmissions (including Basicpower and Ergopower series) for their loaders and heavy equipment. Servicing these machines requires a supplier who understands both the ZF technology and the specific configurations used by these Chinese OEMs.

Tianjin XiaoHang Construction Machinery Co., Ltd. is one of China’s most established ZF transmission specialists, offering 20 years of expertise in this exact field.

Section 1: The LZZF (Liuzhou ZF) Connection

Expertise in Localized Production

Many Liugong machines utilize components from the Liuzhou ZF (LZZF) joint venture. As detailed in our other guides, these LZZF models (like the BP LZZF) may have different internal components (bearings, clutches) and electronics (EC4a) than their German-built counterparts. Sourcing from a supplier who doesn’t understand these differences will lead to errors.

Section 2: The XiaoHang Advantage: Your Hub in China

Why Source from Tianjin XiaoHang Machinery Co.?

- Local Expertise: With 20 years of experience, we have deep knowledge of the specific ZF BOMs used by Liugong, XCMG, and other Chinese OEMs.

- Unmatched Supply Chain: We are strategically located within China’s manufacturing infrastructure. This gives us direct access to the supply chain, ensuring fast lead times and the most competitive pricing on the market.

- Technical Verification: We provide expert technical support to verify your BOM number against the Liugong or XCMG machine model, guaranteeing you get the correct part.

Conclusion: Your Expert Partner for Chinese OEM/ZF Parts

Stop navigating complex international supply chains. Use the supplier that is at the source. Contact XiaoHang Machinery Co. for all your ZF spare parts needs for Liugong and XCMG equipment.

Contact our International Sales Team today for verified compatibility and rapid delivery.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| 5858518@gmail.com | |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

Introduction: What Your Transmission is Telling You

The ZF 4BP230 transmission’s electronic control unit (TCU) monitors for faults and reports them via codes on the display. Understanding these codes is the first step to fast, accurate repair. As a 20-year technical expert, Tianjin XiaoHang Construction Machinery Co., Ltd. explains the most common fault codes.

Section 1: The Most Common Fault Codes

A Guide for Technicians

If your machine shows a fault, check this list:

Code “BA” (Filter Clogged): This code indicates that the transmission fine filter is clogged or the sensor circuit has failed. This is a critical warning; you must replace the filter immediately (e.g., Part No. [0501.298.690]) to prevent oil starvation and pump damage.

Codes “B1” through “B6” (Clutch Slippage): These codes indicate that a specific clutch pack is slipping. For example:

B1: Clutch K1 slippage

B2: Clutch K2 slippage

B3: Clutch K3 slippage

B4: Clutch K4 slippage

B5: Clutch KV (Forward) slippage

B6: Clutch KR (Reverse) slippage

Code “3E” (Speed Sensor Failure): This indicates the output speed sensor signal has failed. This requires checking the sensor (e.g., [0501.328.675]) and its wiring.

Section 2: Sourcing the Solution with XiaoHang Machinery Co.

From Code to Component, Fast

XiaoHang Machinery Co., Ltd. turns diagnostics into solutions.

Fault “BA”? We provide fast lead times on verified ZF filter kits.

Fault “B1-B6”? We stock the complete clutch repair kits (like [4681.298.014] for K1) needed for the overhaul.

Fault “3E”? We supply the correct speed sensors.

Our 20 years of technical support means we can help you confirm the fault code and ship the right part the first time, leveraging our competitive pricing and strong inventory.

Conclusion: The Partner That Speaks ZF

Don’t just read the code, solve it. Contact XiaoHang Machinery Co. for the technical expertise and rapid parts supply to fix any ZF fault.

ZF 4BP230 Maintenance Protocol: Oil (TE-ML 03), Filter Change, and AEB Clutch Calibration

Introduction: Maintenance is Cheaper Than Repair

Proper maintenance is the most effective way to extend the life of a ZF 4BP230 transmission. Skipping oil changes or using the wrong filter leads to contamination, overheating, and component failure. As a 20-year service expert, Tianjin XiaoHang Construction Machinery Co., Ltd. shares the official maintenance protocol.

Section 1: The Oil and Filter Change Procedure

Following the Official ZF Schedule

To ensure longevity, follow this expert protocol:

- First Oil Change: Must be performed after the first 100 operating hours.

- Subsequent Changes: Perform every 1000 operating hours.

- Oil Specification: Use only approved lubricants from the ZF TE-ML 03 list.

- Filter Requirement: You must replace the pressure filter at every oil change. Only use genuine ZF-quality filters (e.g., Part No. [0501.298.690] or [0501.335.480] for BOM 4681.084.018). Using low-quality filters can cause a “BA” (filter clogged) fault code.

Section 2: The Critical Step: AEB Clutch Calibration

Recalibration is Not Optional

After every oil and filter change, you must recalibrate the clutch filling times.

- Tool Required: This requires the ZF standard tool (AEB).

- Purpose: This “clutch adjustment” process optimizes the clutch filling time to compensate for manufacturing tolerances and wear. Failure to do this will result in harsh shifting or slippage.

Section 3: Your One-Stop Maintenance Partner

Sourcing Kits and Expertise from XiaoHang

Tianjin XiaoHang Construction Machinery Co., Ltd. provides a complete maintenance solution:

- One-Stop Sourcing: We supply the correct ZF TE-ML 03 compliant oil and the genuine-quality filters (like [0501.298.690]) in one package.

- Technical Support: Our 20 years of experience means we can provide the technical guidance for the AEB calibration process, ensuring your maintenance is done correctly.

Conclusion: Do Maintenance Right

Protect your investment. Source your verified 4BP230 maintenance kits and get the expert technical support you need from XiaoHang Machinery Co.

Contact our International Sales Team today to order your complete service kits

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| 5858518@gmail.com | |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |