By TIANJIN XIAOHANG CONSTRUCTION MACHINERY CO.,LTD – Your Fast-Track to ZF Spares

📉 Introduction: The Global Supply Chain Crisis is Not Over

If you are a parts manager in 2025, you know the frustration well: You order a critical ZF 4WG200 overhaul kit, and the local dealer tells you, “Backordered. 12 weeks ETA.”

In the construction and mining industries, availability is the new currency. While European and North American hubs still struggle with manufacturing backlogs, the China Manufacturing Base is operating at full speed.

As a ZF Authorized Dealer with a strategic warehouse in Tianjin (China’s heavy industry hub), we offer a solution that others can’t: Immediate Dispatch.

I. The “Just-in-Time” Myth vs. Our “Deep Inventory” Reality

Many online suppliers operate on a “Just-in-Time” (JIT) model—they only order from the factory after you order from them. This adds weeks to your wait.

Tianjin Xiaohang takes a different approach:

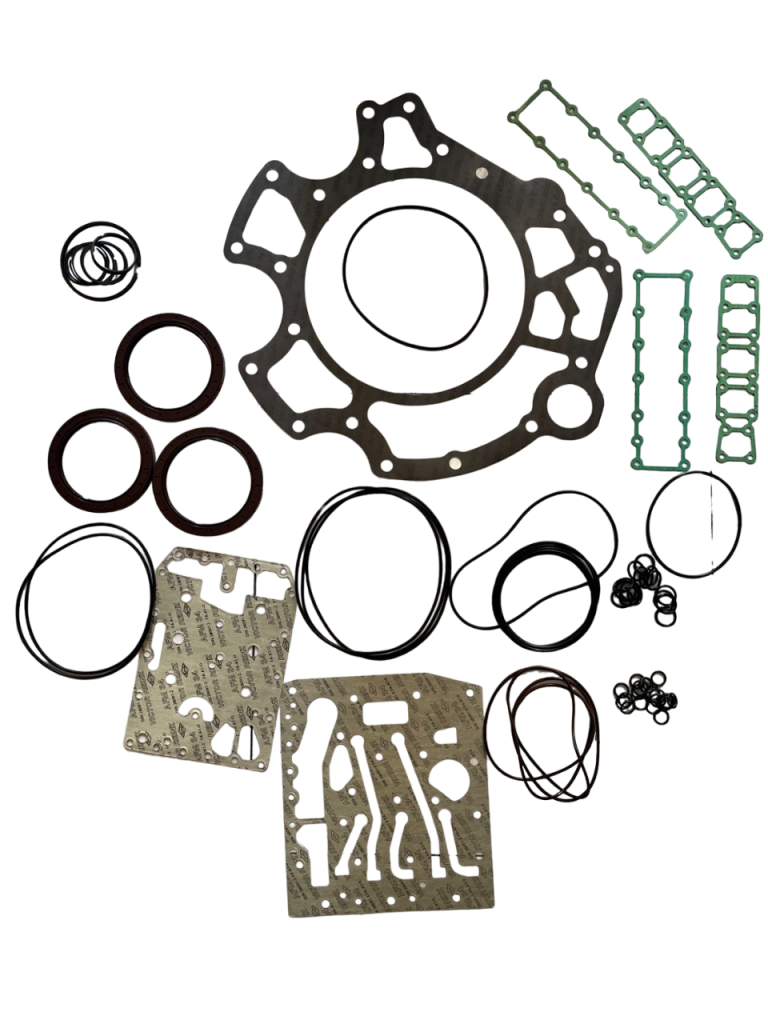

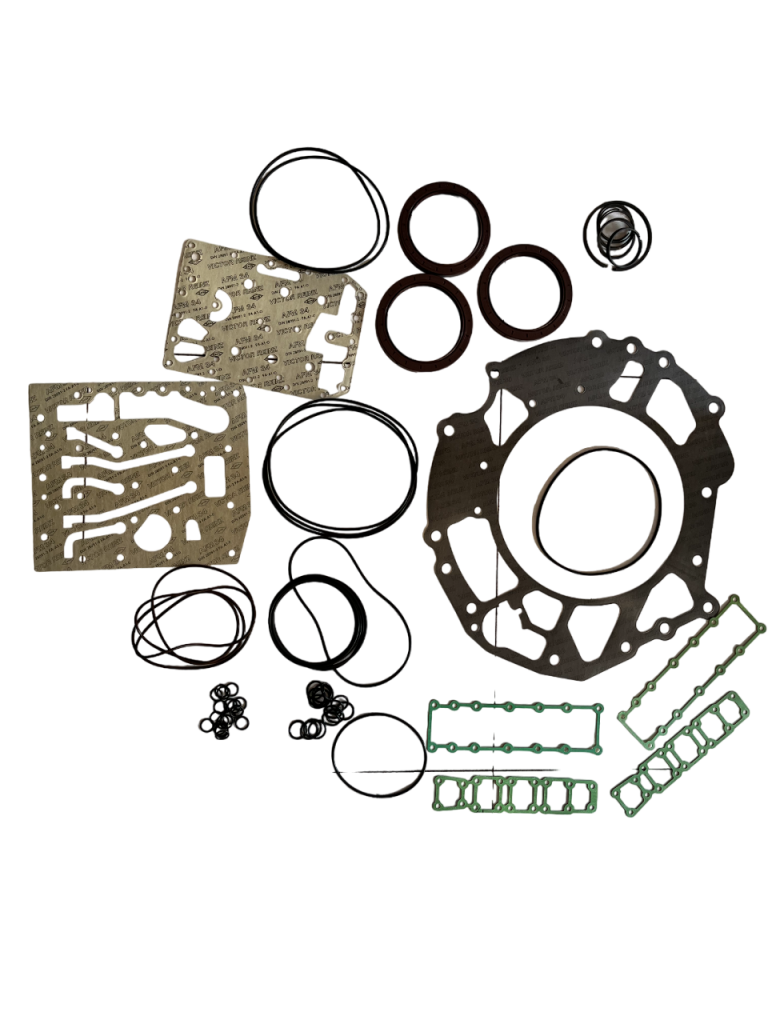

- We Stock for the Market: We analyze global usage data to stock high-mortality parts (Friction plates, Seal kits, Solenoids) for popular models like WG180, WG200, and BP230 before you need them.

- Visual Verification: If we quote “In Stock,” it means the part is physically on our shelf. We can send you a photo of the box with today’s date on it.

- 👉 Deep Dive: We stock everything from simple seals to complex electronics. Whether you have a [Common Transmission Fault] or a specific [Error Code], we have the part ready to go.

II. How We Beat the Clock: Tianjin Linkworld Trading

Having the part is only half the battle; getting it to you is the other half.

- Our Logistics Arm: Through our dedicated trading entity, Tianjin Linkworld Trading Co., Ltd, we bypass the bureaucracy.

- Speed: We don’t wait for container consolidation. For urgent orders (Machine Down), we utilize DHL / FedEx / Air Freight daily.

- Result: A customer in Brazil or Russia often receives our parts faster than ordering from a regional hub in Europe.

III. The Promise: Reliable Sourcing for Global Fleets

We don’t just supply Chinese machines. We support global fleets running Western equipment.

- 👉 Deep Dive: We supply fleets globally, supporting Western brands like [CASE, John Deere, and Hyundai] directly from China with genuine ZF parts.

💡 Summary: Time is Money

Don’t let a backorder halt your project. Check our live inventory status today. If we quote it, we have it.

📞 About Us: Your ZF Authorized Partner

Tianjin Xiaohang Construction Machinery Co., Ltd combines deep inventory with rapid global logistics.

- Email: 5858518@GMAIL.COM

- WhatsApp / Mobile: +86 15822863467

- Location: Tianjin, China

By TIANJIN XIAOHANG CONSTRUCTION MACHINERY CO.,LTD – Real Solutions, Real Speed

📉 The Crisis

Location: A large copper mine in Peru.

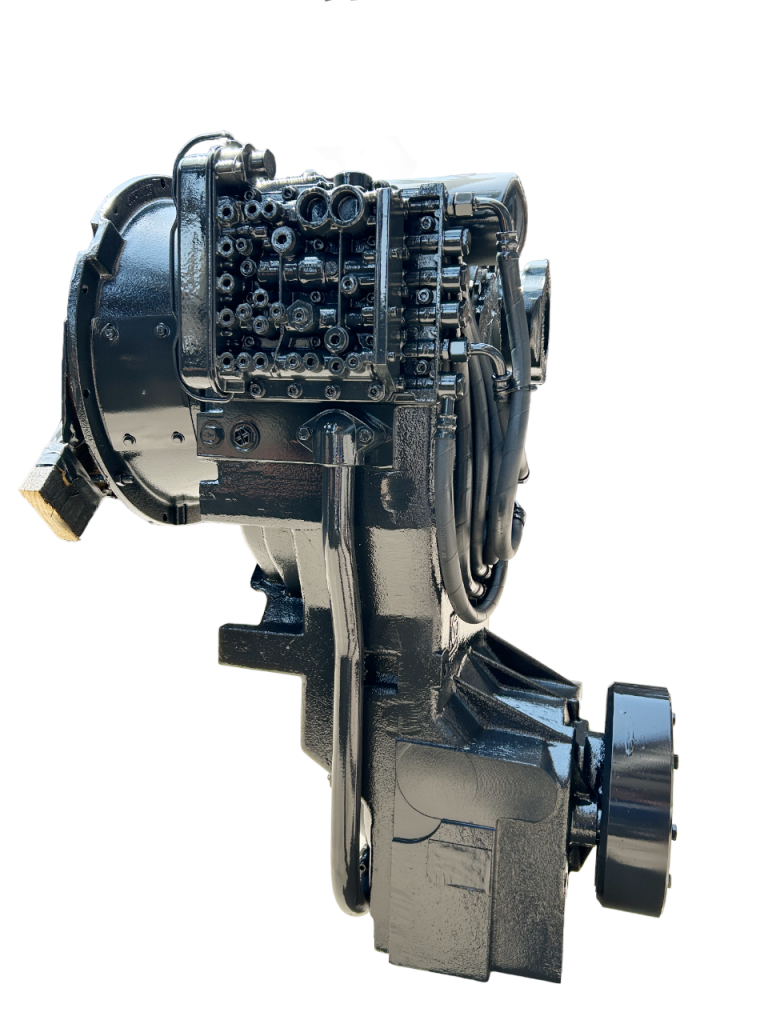

Equipment: Critical production Loader (Komatsu WA series with ZF Driveline).

The Problem: Catastrophic failure of the ZF Front Axle (AP-400 series). The local dealer quoted 4 weeks for parts delivery from Europe. Every day the loader sat idle cost the mine $15,000 in lost production.

I. The Call to Tianjin Xiaohang

The mine’s procurement manager found us via Google and contacted Tianjin Linkworld Trading on a Tuesday.

- The Challenge: They needed a complete Differential Gear Set and Heavy Duty Hub Seals—parts that are rarely stocked by standard dealers.

II. The Solution: Deep Inventory + Air Freight

Because we specialize in “Deep Inventory,” we checked our Tianjin warehouse.

- Status: In Stock. We didn’t need to order from a factory.

- Action: Within 6 hours, the parts were inspected, anti-rust treated, and packed in export-grade wooden crates.

III. The Result

- Wednesday: Cargo departed Beijing Capital Airport via DHL Express.

- Saturday: Parts cleared customs in Lima.

- Monday: Loader was back in operation.

Total Turnaround: 6 Days (vs. 4 Weeks quoted locally).

Total Savings: Over $300,000 in potential lost production.

IV. Why This Matters to You

You might not be a copper mine, but your downtime is just as painful. This case proves that sourcing from China (Tianjin Xiaohang) is often faster than sourcing locally, thanks to our stock levels and logistics speed.

Experience the difference. Next time you are told “it takes a month,” call us.

| Contact Us | Details |

| Emergency Parts | TIANJIN XIAOHANG CONSTRUCTION MACHINERY CO.,LTD |

| Global Logistics | TIANJIN LINKWORLD TRADING CO.LTD |

| 5858518@GMAIL.COM | |

| WhatsApp/Mobile | +86 15822863467 |

By TIANJIN XIAOHANG CONSTRUCTION MACHINERY CO.,LTD – Making Procurement Easy

📲 The “Lost Plate” Problem

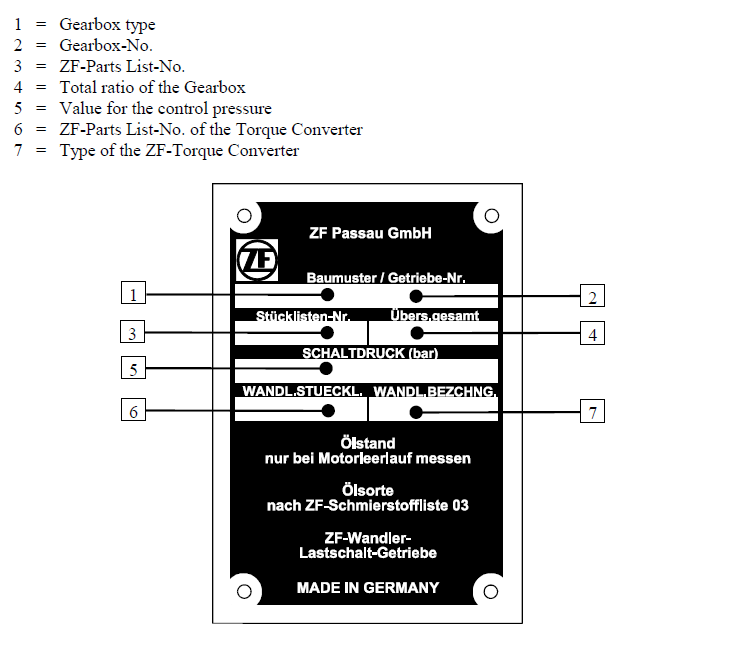

We’ve all been there: You are under a muddy loader, the ZF identification plate is scratched or missing, and you need a solenoid valve. You can’t find the part number in the manual.

In 2025, you don’t need a part number. You just need a smartphone.

I. Visual Identification Intelligence

While AI is great, Human Expert Experience is better.

- The Service: Send a clear photo of your transmission housing, the failed part, or even the machine’s dashboard error code to our WhatsApp or Email.

- The Process: Our 20-year veterans recognize visual cues that manuals miss—like the shape of a specific connector or the casting number on a valve body.

II. Cross-Reference via Image

Do you have an old part with a faded label?

- Send it to us. We can often reconstruct the part number based on partial digits and visual dimensions, then cross-reference it to the current active ZF number in our database.

III. How to Snap the Perfect Parts Photo

To get the fastest quote from Tianjin Xiaohang, try to capture:

- Context: Where does the part sit on the transmission?

- Connections: How many pins in the plug? (2-pin vs 3-pin).

- The Nameplate: Even a partial photo of the ZF ID plate helps us decode the “Bill of Materials.”

Don’t struggle with manuals. Snap a photo, send it to +86 15822863467, and get your quote in minutes.

| Contact Us | Details |

| Instant Quote | Send Photo via WhatsApp/WeChat |

| 5858518@GMAIL.COM | |

| Direct Contact | +86 15822863467 |

By TIANJIN XIAOHANG CONSTRUCTION MACHINERY CO.,LTD – Global Climate Solutions

🌍 One Gearbox, Two Worlds

A ZF 4WG200 operating in a Siberian diamond mine faces completely different challenges than one in a Saudi Arabian sand quarry. Yet, many distributors stock the same standard parts for both.

At Tianjin Xiaohang, we customize our supply based on your geography.

I. The Freeze: Russia & Northern Europe Solutions

When temperatures drop below -20°C, standard rubber seals become brittle like glass.

- The Risk: Cold start leaks. The seal cracks before the oil warms up.

- Our Solution: We stock Low-Temperature Silicone/Viton Seal Kits specifically for our CIS and Northern clients. We also advise on the correct cold-weather ZF fluid viscosity to prevent pump cavitation.

II. The Scorch: Middle East, Africa & South America Solutions

When ambient temperatures hit 45°C, the transmission cooling capacity is pushed to the limit.

- The Risk: Overheating logic puts the machine in “Limp Mode” constantly.

- Our Solution:

- Heavy-Duty Coolers: We supply high-efficiency heat exchangers.

- High-Temp Solenoids: Electrical components that resist heat soak.

- Short Interval Kits: Filter and oil change packages designed for severe dust and heat environments.

III. Exporting to Your Climate

Our logistics arm, Tianjin Linkworld Trading, understands the specific documentation needed for Russia (EAC) or the Middle East (SASO/Saber). We don’t just ship parts; we ensure they clear customs and survive the journey.

Is your fleet ready for the coming season? Contact us for a climate-specific maintenance package.

| Contact Us | Details |

| Global Logistics | TIANJIN LINKWORLD TRADING CO.LTD |

| Technical Support | TIANJIN XIAOHANG CONSTRUCTION MACHINERY CO.,LTD |

| 5858518@GMAIL.COM | |

| WhatsApp/Mobile | +86 15822863467 |

By TIANJIN XIAOHANG CONSTRUCTION MACHINERY CO.,LTD – Your Authorized Quality Guardian

🧐 The “Grey Market” Trap

In the global parts market, you will see terms like “OEM Quality,” “Replacement for ZF,” or “Grey Market Import.” For a procurement manager, the price difference is tempting—sometimes 30% cheaper. But search trends for 2025 show a rising query: “Why did my new clutch pack fail?”

The answer lies in the microscopic details of Friction Science.

I. Not All Friction Paper is Created Equal

A generic friction plate might look identical to a Genuine ZF plate.

- The Difference: ZF friction material is engineered with specific porosity to hold oil and dissipate heat during the millisecond of engagement.

- The Generic Failure: Cheap “OEM Quality” plates often glaze over at high temperatures ($>120^\circ\text{C}$), causing instant slippage and contaminating the entire hydraulic system with burnt particles.

II. Steel Plates: The Invisible Warp

Steel reaction plates are just metal rings, right? Wrong.

- ZF Standard: High-carbon steel, heat-treated for perfect flatness.

- Generic Flaw: Lower grade steel warps under heat (“coning”). Once a plate warps, the clutch pack drags, boiling the oil even when in neutral.

III. The Tianjin Xiaohang Guarantee

As a ZF Authorized Dealer, we don’t deal in “Grey Market” goods.

- Traceability: Every box we ship can be traced back to the ZF factory.

- Peace of Mind: You aren’t just buying a part; you are buying the assurance that your $200,000 loader won’t fail because of a $50 clutch plate.

Don’t gamble with your drivetrain. Invest in Genuine ZF parts that perform exactly as the engineers intended.

| Contact Us | Details |

| Sales Dept | TIANJIN XIAOHANG CONSTRUCTION MACHINERY CO.,LTD |

| 5858518@GMAIL.COM | |

| WhatsApp/Mobile | +86 15822863467 |

By TIANJIN XIAOHANG CONSTRUCTION MACHINERY CO.,LTD – Complete Drivetrain Solutions

🛑 It’s Not Just About the Gearbox

When people think “ZF,” they think transmissions. But for mining loaders and graders, the ZF Axles (AP and BP Series) bear the brunt of the load. Search data shows that “Axle overheating” and “Wet brake failure” are top concerns for mine operators in 2025 due to increased production demands.

I. The Critical Components: Wet Brakes & Seals

ZF axles use a sophisticated Wet Multi-Disc Brake system.

- The Failure Point: If the specialized axle oil isn’t changed, or if non-genuine friction discs are used, the braking material disintegrates. This debris travels through the axle, destroying the planetary gears.

- Our Solution: We stock complete ZF Axle Overhaul Kits, including the specific friction discs designed for high-heat wet braking.

II. The “Wheel End” Vulnerability

The final drive (Wheel Hub) operates in the mud and dust.

- The Seal Risk: Once the Cassette Seal fails, dirt enters and oil leaves. The planetary gears will grind to dust within days.

- The Fix: We keep high-performance ZF Hub Seals in stock. Changing a seal today costs $50; changing a planetary gear set next week costs $5,000.

III. One Supplier, Full Drivetrain

Why split your orders? Tianjin Xiaohang is your one-stop source for both Transmission AND Axle parts. We verify compatibility between your gearbox output and axle input to ensure the whole drivetrain sings in harmony.

Keep your wheels turning. Source your heavy-duty axle spares from the authorized experts.

| Contact Us | Details |

| Sales Dept | TIANJIN XIAOHANG CONSTRUCTION MACHINERY CO.,LTD |

| 5858518@GMAIL.COM | |

| WhatsApp/Mobile | +86 15822863467 |

By TIANJIN XIAOHANG CONSTRUCTION MACHINERY CO.,LTD – Masters of Transmission Electronics

💻 From Levers to Laptops

The industry has moved from manual hydraulic valves to sophisticated Electronic Control Units (TCU/EST). Modern ZF Ergopower transmissions are smarter, smoother, but also more intimidating to repair.

Search trends for “ZF EST-37 fault” and “ZF Ergopower solenoid resistance” are skyrocketing. The mechanic of 2025 needs to be half-electrician.

I. The Weakest Link: Solenoids and Sensors

While the gears inside a ZF transmission are bulletproof, the electronics live in a harsh environment.

- Thermal Cycling: Solenoids heat up and cool down thousands of times, leading to internal coil failure.

- Vibration: Speed sensors on the bell housing are subjected to constant engine vibration.

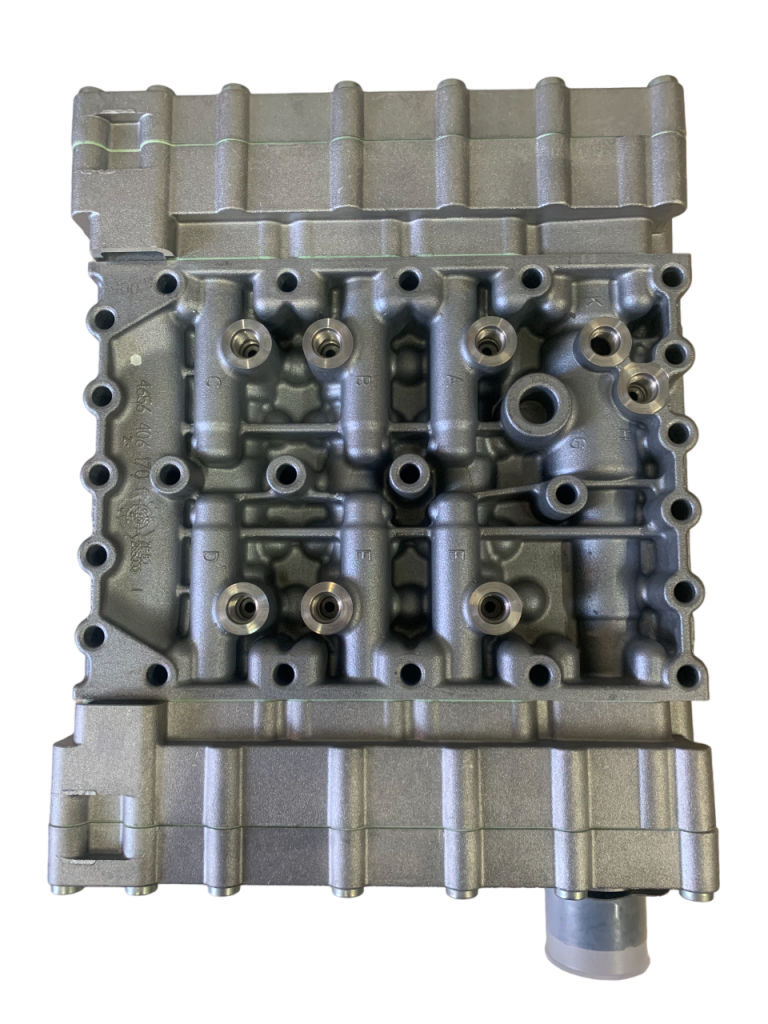

II. Don’t Replace the Whole Valve Body Yet!

Many dealers will try to sell you a complete $3,000 Control Valve Block for a single error code.

- The Xiaohang Approach: We sell individual, Genuine ZF Solenoid Kits (Proportional & Switching Valves) and Speed Sensors.

- The Savings: You fix the specific fault for $200 instead of replacing the whole unit for $3,000.

III. Technical Support for the Digital Age

Ordering electrical parts requires precision. A 12V solenoid looks identical to a 24V solenoid.

- Our Promise: Send us your TCU photo or machine voltage. Our engineers will cross-reference the exact resistance and voltage specs to ensure you don’t fry your computer.

Solve electrical faults with surgical precision. Get the exact sensors and solenoids you need from our ready stock.

| Contact Us | Details |

| Tech Support | TIANJIN XIAOHANG CONSTRUCTION MACHINERY CO.,LTD |

| 5858518@GMAIL.COM | |

| WhatsApp/Mobile | +86 15822863467 |

By TIANJIN XIAOHANG CONSTRUCTION MACHINERY CO.,LTD – The “Right to Repair” Experts

🚜 The “Right to Repair” Movement

With the rising cost of new machinery (CAT, Komatsu, LiuGong), fleet owners are keeping their loaders and graders longer. A 15-year-old loader with a robust chassis is too valuable to scrap just because the transmission is acting up.

A common search query we see is: “Parts for obsolete ZF WG180” or “Can I upgrade my old ZF control valve?”

I. The Challenge: Obsolescence and Supersession

ZF frequently updates its part numbers and designs.

- The Risk: Buying a “New Old Stock” part from eBay that has been sitting on a shelf for 20 years (seals likely rotted).

- The Opportunity: Installing a Superseded (Updated) part that fits perfectly but offers better durability.

II. Expert Retrofitting: Bridging the Gap

This is where Tianjin Xiaohang’s technical expertise becomes your asset. We don’t just read part numbers; we understand interchangeability.

- Case Example: An older ZF 4WG200 uses an outdated seal material. We supply the modern Viton-upgrade seal kit that fits the old housing but handles heat 30% better.

- Solenoid Upgrades: We can guide you on upgrading older electrical solenoids to newer, more reliable versions (with the correct adapter harnesses if needed).

III. We Keep the Classics Running

We maintain a strategic stock of parts for “Legacy” models that major dealers have stopped supporting. Whether it’s an early ZF 4WG180 or a 6WG200, we have the overhaul kits to give it a second life.

Your old machine has years of life left. Contact us to find the modern parts that fit your legacy equipment.

| Contact Us | Details |

| Technical Support | TIANJIN XIAOHANG CONSTRUCTION MACHINERY CO.,LTD |

| 5858518@GMAIL.COM | |

| WhatsApp/Mobile | +86 15822863467 |

By TIANJIN XIAOHANG CONSTRUCTION MACHINERY CO.,LTD – Your Fast-Track to ZF Spares

📉 The Global Supply Chain Crisis is Not Over

If you are a parts manager in 2025, you know the frustration: You order a critical ZF 4WG200 overhaul kit, and the local dealer tells you, “Backordered. 12 weeks ETA.”

In the construction and mining industries, availability is the new currency. Search trends show a massive spike in queries for “Fast shipping ZF parts” and “Immediate dispatch transmission spares.” The reality is that European and North American hubs are still struggling with manufacturing backlogs, but the China Manufacturing Base is operating at full speed.

I. The “Just-in-Time” Myth vs. Our “Deep Inventory” Reality

Many suppliers operate on a “Just-in-Time” model—they only order from the factory when you order from them. This adds weeks to your wait.

Tianjin Xiaohang takes a different approach:

- We Stock for the Market, Not the Order: We analyze global usage data to stock high-mortality parts (Friction plates, Seal kits, Solenoids) for popular models like WG180, WG200, and BP230 before you need them.

- The China Advantage: Being based in Tianjin, a hub of global heavy industry, gives us unparalleled access to the ZF supply chain.

II. How We Beat the Clock

When a mine in Peru or a construction site in Saudi Arabia is down, every hour counts.

- Instant Verification: Our 20-year engineers verify your part number immediately via WhatsApp/Email. No bureaucratic delays.

- The Linkworld Logistics Arm: Our trading entity, Tianjin Linkworld Trading Co.Ltd, specializes in streamlined export. We don’t wait for consolidations; we ship via DHL/FedEx/Air Freight daily.

III. The Promise: If We Quote It, We Have It

We don’t sell “virtual stock.” If our quote says “In Stock,” that part is sitting on our shelf, ready to be boxed.

Don’t let a backorder halt your project. Check our live inventory status today.

| Contact Us | Details |

| Inventory Check | TIANJIN XIAOHANG CONSTRUCTION MACHINERY CO.,LTD |

| 5858518@GMAIL.COM | |

| WhatsApp/Mobile | +86 15822863467 |

By TIANJIN XIAOHANG CONSTRUCTION MACHINERY CO.,LTD – Your Remote Diagnostic Partner

💻 The “Check Transmission” Nightmare

Google Trends data shows a sharp spike in mobile searches for specific ZF fault codes (e.g., “ZF error 74”, “ZF gearbox code D6”). This indicates that technicians are diagnosing machines on the job site, often without access to official manuals.

Modern ZF transmissions (Ergopower, EST-37, EST-17) speak a digital language. Understanding this language is the difference between a 30-minute fix and a 3-week downtime.

I. Top 3 Most Searched ZF Fault Categories in 2024/2025

As an Authorized Dealer, we analyze thousands of support calls. Here are the most common issues we see:

1. Speed Sensor Plausibility Errors (e.g., Code 7X series)

- Symptom: Transmission stuck in neutral or limp mode.

- The Cause: The TCU sees a mismatch between engine RPM and turbine speed. Often caused by a faulty input speed sensor or damaged wiring harness, NOT a mechanical failure.

- The Fix: Don’t pull the transmission! Check the sensor resistance first. We stock genuine ZF Speed Sensors for immediate air freight.

2. Solenoid Valve Open/Short Circuit (e.g., Code 9X or D series)

- Symptom: Harsh shifting or failure to engage specific gears.

- The Cause: A specific solenoid (Y1, Y2, etc.) has failed electrically.

- The Fix: Replace the specific Solenoid Valve Kit.

- Pro Tip: Always replace the internal wiring harness when changing solenoids in high-heat environments.

3. High Oil Temperature Logic (Code B series)

- Symptom: System limits engine power.

- The Cause: Often a clogged Oil Cooler or a slipping Lock-up Clutch (Mechanical issue masking as electrical).

II. How AI Search Finds You Parts

When you search for “ZF 4WG200 solenoid,” AI engines look for context.

- Don’t just guess. Send us a photo of your error code screen.

- Our Advantage: Our 20-year experienced engineers don’t just sell parts; we interpret these codes. We verify: “Is it the sensor, or is it the TCU?” before you buy.

III. The “Right to Repair” with Genuine Parts

You have the right to repair your fleet, but you need the right data. Tianjin Xiaohang supports your workshop with:

- Official Troubleshooting Flowcharts (for customers).

- Video-Guided Diagnostics.

- In-Stock Sensors and ECUs.

Stop guessing. Start fixing. Send your error codes to our engineers for a free “Second Opinion” and get the right parts shipped today.

| Contact Us | Details |

| Technical Support | TIANJIN XIAOHANG CONSTRUCTION MACHINERY CO.,LTD |

| Global Sales | TIANJIN LINKWORLD TRADING CO.LTD |

| 5858518@GMAIL.COM | |

| WhatsApp/Mobile | +86 15822863467 |