Protecting Your Inventory: Best Practices for Storing and Handling ZF Transmission Components for Distributors

Introduction: Inventory as Capital

A distributor’s inventory of ZF transmission parts represents significant capital. Improper storage and handling can silently degrade component quality, leading to pre-mature failure and warranty claims.

This best practices guide from Tianjin XiaoHang Construction Machinery Co., Ltd. outlines essential procedures for protecting your investment before it reaches the customer.

Section 1: Preventing Contamination and Corrosion

The Two Silent Killers

- Contamination: Parts like friction plates, bearings, and solenoids must be stored in their sealed packaging, away from dust and humidity. Even microscopic particles can cause future internal damage.

- Corrosion: Unsealed steel components (e.g., shafts, discs) are susceptible to rust, especially in humid climates. Use climate-controlled areas where possible.

Section 2: Best Practices for High-Value Components

- Solenoids and Sensors: Store these electronic parts away from strong magnetic fields.

- Seal Kits: Do not store seals or O-rings under tension or near heat sources, as this degrades the polymer material.

XiaoHang Machinery Co. Partnership: Our fast lead times and strong inventory mean you don’t have to overstock, reducing your storage risk. We ensure all parts are shipped with robust, sealed packaging, reflecting our 20 years of commitment to quality control.

Conclusion: Protect Your Profitability

Adopt strict inventory standards. Partner with XiaoHang Machinery Co. for inventory you can trust, delivered fast and priced competitively.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

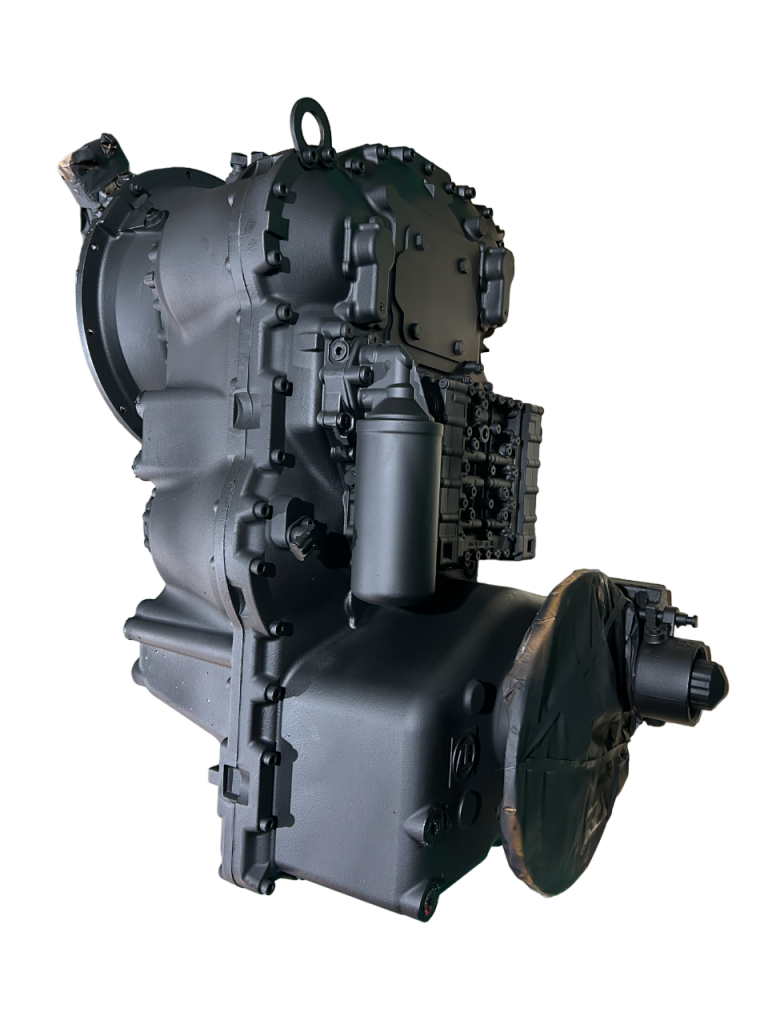

Beyond Loaders: Sourcing Specialized ZF Transmission and Axle Parts for Crane and Mining Equipment

Introduction: Specialized Demands, Specialized Parts

ZF transmissions and axles in specialized vehicles (cranes, mining trucks) operate under extreme torque and temperature stress. These applications require specific, heavy-duty component variants that differ from standard loader parts.

This guide from Tianjin XiaoHang Construction Machinery Co., Ltd. helps distributors navigate the nuances of procuring specialized ZF parts for high-demand environments.

Section 1: The Nuance of Specialized Part Numbers

Why Standard Parts Will Fail in Severe Duty

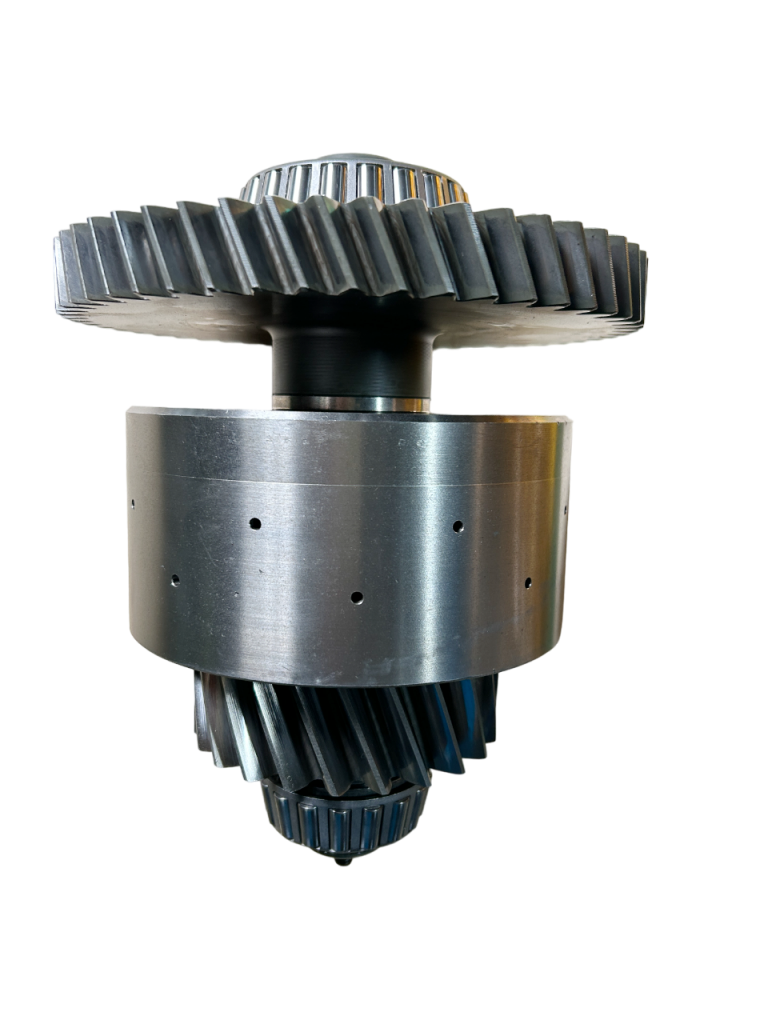

ZF components for mining and crane applications often feature different metallurgy (e.g., for gear sets) or cooling provisions (e.g., larger oil coolers). Procurement must target the specific Heavy Duty (HD) or specialized application BOM code.

Section 2: High-Value Specialized Inventory

Components Where Quality is Critical

We focus on supplying parts for: 1. High-Load Gear Sets: Engineered for extreme torque. 2. Heavy-Duty Bearings: Required to withstand constant vibration and load. 3. Axle Components: Specialized axle differentials and final drives are key procurement areas.

XiaoHang Machinery Co. Advantage: Our experience with diverse applications allows us to provide unparalleled technical support to verify specialized BOM numbers, ensuring your crane and mining customers receive parts that match their severe operating environment. We ensure fast lead times on these high-value, specialized spares.

Conclusion: Specialized Parts Demand Specialized Suppliers

Partner with XiaoHang Machinery Co. to secure the specific, high-durability ZF spares required for crane and mining operations.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

Advanced ZF Solenoid Valve Testing and Replacement: A Guide to Troubleshooting Electronic Shifting Failures

Introduction: The Precision of Electronic Control

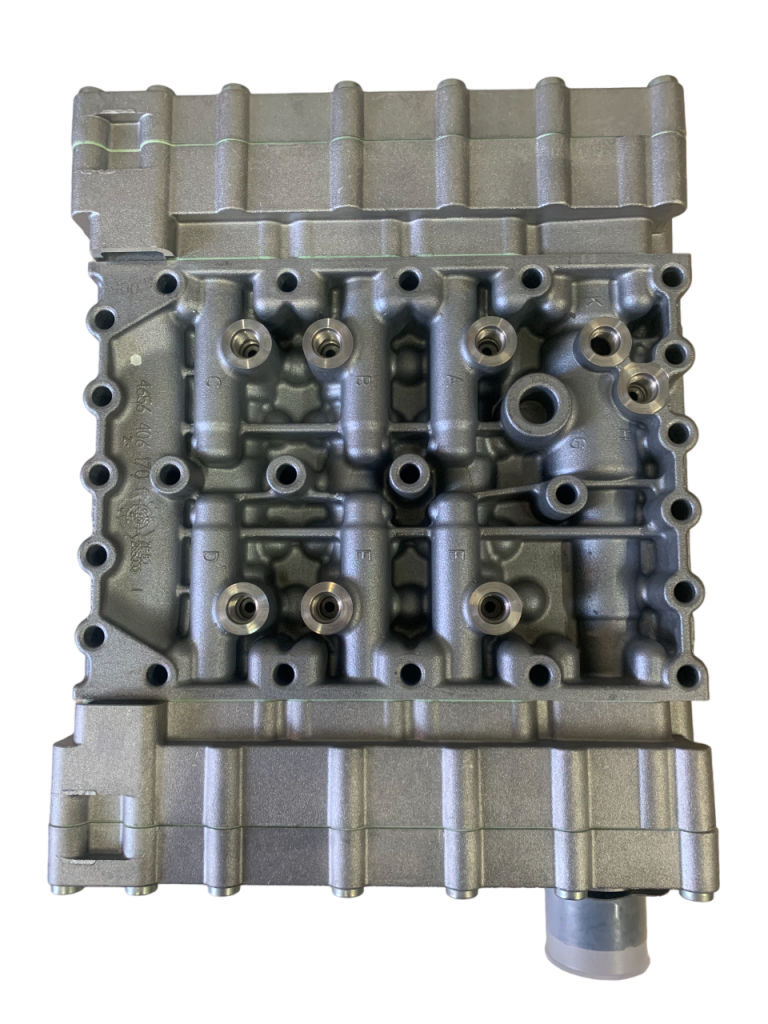

Solenoid valves are electromechanical actuators controlling fluid flow to the clutch packs. Their precise operation is essential for smooth, reliable shifting. Failure requires targeted diagnosis and verified replacement parts.

This advanced guide from Tianjin XiaoHang Construction Machinery Co., Ltd. provides a technical overview of solenoid testing and best practices for replacement procurement.

Section 1: Diagnosing Solenoid Failure

Advanced Technical Checks

- Electrical Testing: Technicians must check the solenoid’s resistance and continuity against OEM specifications. Deviations indicate coil damage.

- Pressure Testing: A non-functional solenoid will show an absence of expected hydraulic pressure at the clutch test ports.

- Contamination Check: Solenoids often fail due to sludge or metallic particles lodging in the valve body, emphasizing the importance of high-quality filters (see Article No. 6).

Section 2: Sourcing Verified Solenoids

Avoiding Counterfeit Electronic Parts

- Verification: Due to software calibration, solenoid replacements must strictly adhere to the BOM part number.

- XiaoHang Quality Assurance: Our 20 years of experience ensures we supply only verified electronic components that match the required pressure and flow characteristics. We leverage our efficient supply chain to offer competitive pricing and fast lead times on these critical electrical parts.

Conclusion: Ensure Smooth Shifting with Verified Electronics

Trust XiaoHang Machinery Co.’s technical authority to guide your procurement of sensitive ZF electronic components.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

Preventing Leaks and Pressure Loss: The Critical Role of High-Quality ZF Seal and Gasket Kits in Transmission Repair

Introduction: The Integrity Barrier

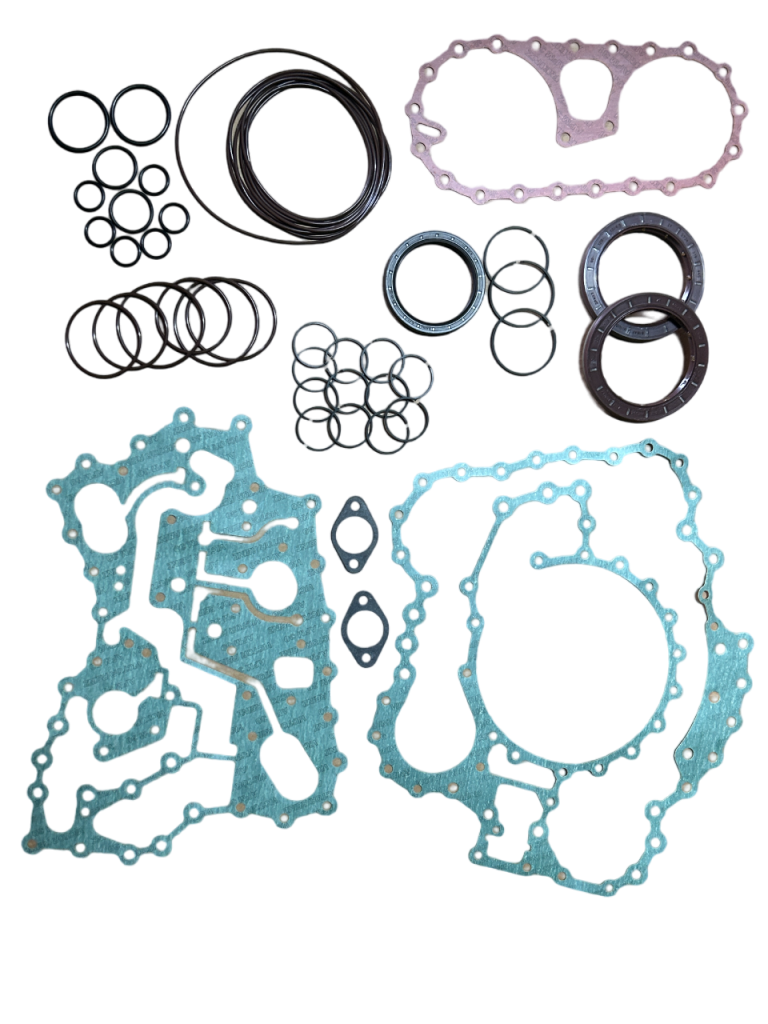

Seals and gaskets are the transmission’s integrity barrier. Failure of a seal leads to oil loss, contamination ingress, and, most critically, internal hydraulic pressure loss, directly causing clutch slippage. Sourcing high-quality, durable sealing kits is paramount for a successful repair.

This specialized guide from Tianjin XiaoHang Construction Machinery Co., Ltd. outlines the best practices for sourcing and installing ZF seal and gasket kits.

Section 1: The Hidden Risks of Low-Quality Seals

Don’t Compromise on Material Quality

Low-quality seals are susceptible to: 1. Thermal Degradation: High transmission oil temperatures cause cheap materials to harden and crack. 2. Chemical Incompatibility: Non-approved materials swell or shrink when exposed to synthetic ZF fluids.

Section 2: Procurement Strategy for Sealing Kits

The XiaoHang Quality Standard

- Material Specification: We emphasize the use of high-grade materials (e.g., Viton or specialized NBR compounds) that resist heat and chemical damage.

- Comprehensive Kits: XiaoHang Machinery Co. supplies complete sealing kits tailored to specific ZF models, ensuring technicians have all necessary components (O-rings, PTFE rings, gaskets) in the correct materials. We guarantee fast lead times on these high-demand kits.

Conclusion: Seal the Success of Your Repair

Ensure the longevity of your ZF repairs by relying on high-quality, verified sealing solutions. Contact XiaoHang Machinery Co. today to secure your next complete seal and gasket kit.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

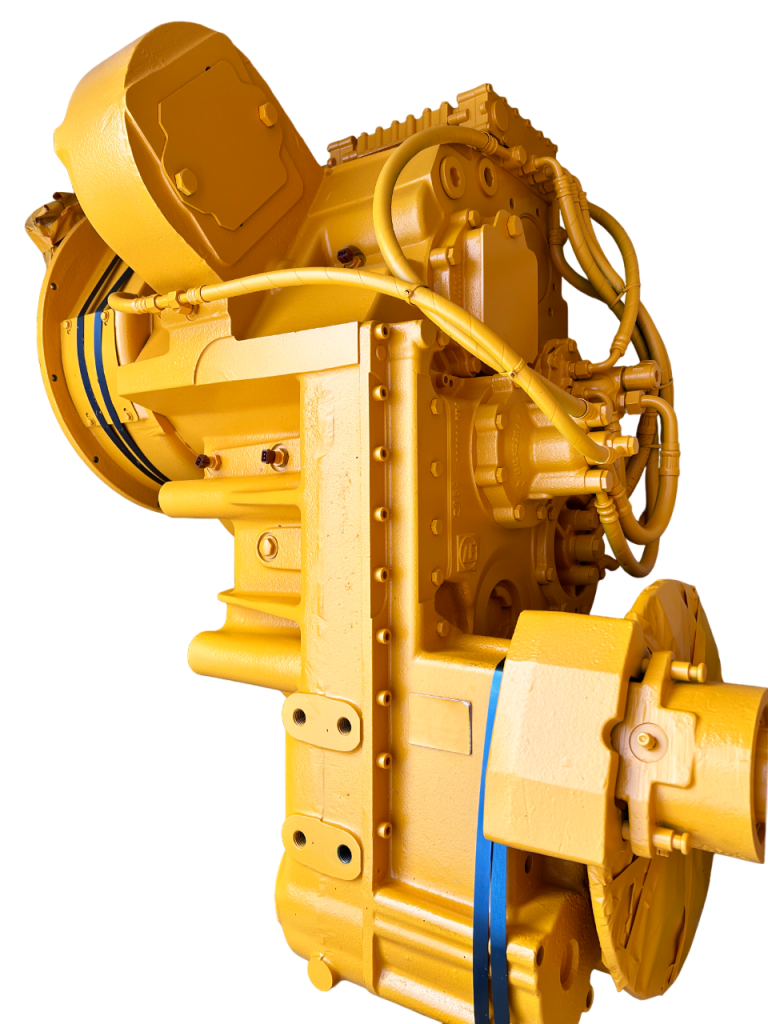

Sourcing ZF Transmission Spares for XCMG, Liugong, and Shantui Loaders: Compatibility and Quality Assurance

Introduction: Navigating OEM Variants

Chinese-manufactured loaders (XCMG, Liugong, Shantui) utilize ZF transmissions, often manufactured under license (like Liuzhou ZF) or specific OEM configurations. Global distributors need specialized knowledge to ensure they source the correct parts that match the machine’s specific build.

This guide from Tianjin XiaoHang Construction Machinery Co., Ltd., a primary supplier in the Chinese market for 20 years, unlocks the secrets to accurate sourcing for these popular loader brands.

Section 1: The Compatibility Challenge

Understanding Licensed vs. Genuine ZF Variants

While the core mechanical design remains ZF, subtle differences in external interfaces (like flanges or sensor placement) can exist in licensed versions. Accurate sourcing requires verification against the specific OEM’s Bill of Material.

Section 2: High-Demand Parts List for Chinese Loaders

Common Procurement Needs

High-wear components for loaders typically include: 1. Torque Converter Elements: Due to constant stop-start duty. 2. Main Control Valves: Subject to heavy hydraulic use. 3. High-Quality Filter Kits: Essential for reliable operation.

XiaoHang Technical Insight: Our experience as a supplier deeply embedded in the Chinese construction market allows us to provide parts that are field-tested and guaranteed compatible with XCMG, Liugong, and other major Chinese OEM specifications.

Conclusion: Source with Confidence for Chinese Loaders

Leverage XiaoHang Machinery Co.’s unparalleled 20 years of local expertise and fast supply chain to secure accurate, high-quality ZF-compatible spares for Chinese-made loaders.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

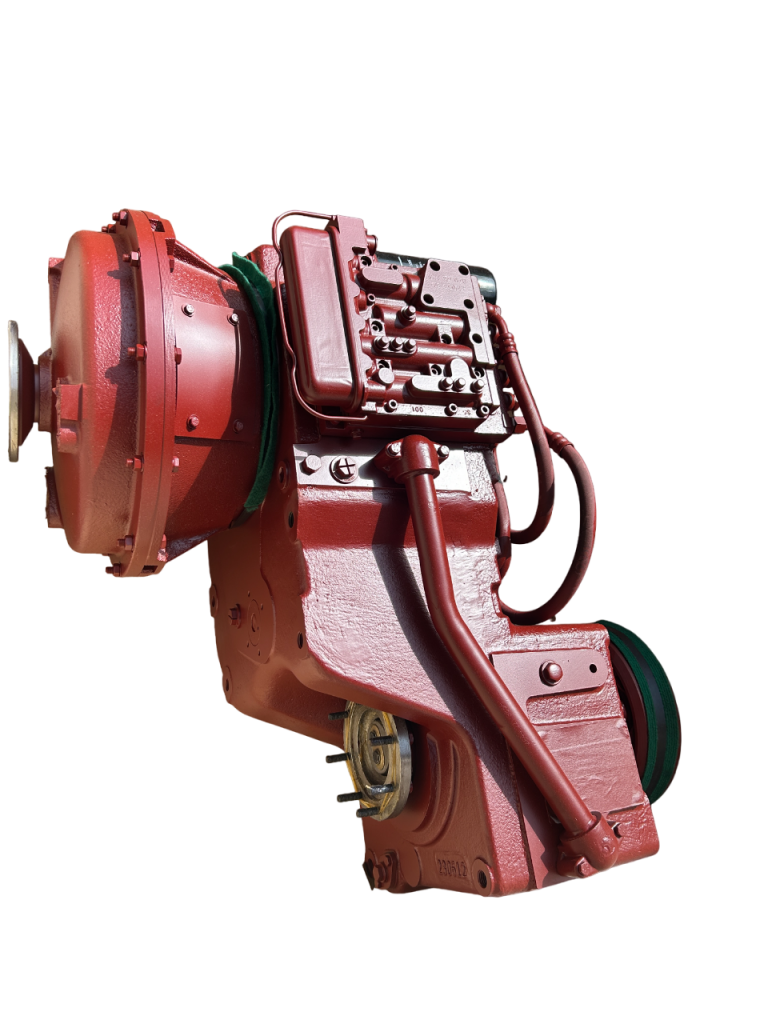

ZF Transmission Repair vs. Replacement: A Distributor’s Guide to Calculating ROI and Sourcing Overhaul Kits

Introduction: Maximizing Customer Value

When a ZF transmission fails, the critical decision is whether to perform a comprehensive overhaul (repair) or replace the entire unit. For procurement managers, this decision is dictated by the cost-effectiveness and the reliability of the available overhaul parts.

This guide from Tianjin XiaoHang Construction Machinery Co., Ltd. provides the framework for this ROI calculation and reinforces the reliability of sourcing high-quality overhaul components from our expert inventory.

Section 1: Calculating the Repair vs. Replacement Threshold

The Financial Metrics for Overhaul Success

Repair is typically advantageous if the cost of high-quality overhaul kits (clutch packs, seals, bearings), plus labor, remains below 50-60% of the cost of a new replacement unit.

- Risk Factor: The key variable is the quality of the overhaul kit. Using substandard components voids the cost advantage and risks immediate failure.

Section 2: The XHC Supply Chain Advantage for Overhauls

Guaranteeing Kit Quality and Speed

XiaoHang Machinery Co.’s 20 years of repair-informed experience means we stock comprehensive, verified overhaul kits (e.g., for 6WG310 or 4WG200) that include every necessary bearing, bushing, seal, and clutch plate.

- Cost & Speed: We provide highly competitive pricing and fast lead times on these complete kits, ensuring your customer receives a cost-effective, high-quality overhaul solution without delay.

Conclusion: Invest in Reliable Overhauls

Make the most profitable decision with confidence. Contact XiaoHang Machinery Co. today to consult on comprehensive overhaul kit pricing and technical details.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

ZF BP230 and BP210 Transmissions: Sourcing Critical Spare Parts and Understanding Compatibility Difference

Introduction: Specialized Expertise for BP Series

The BP (Bus-Pneumatic) series of ZF transmissions, often used in specialized equipment, requires targeted expertise for parts sourcing. Confusion between the BP230 and BP210 models can easily lead to costly errors in high-value component procurement.

This specialized guide from Tianjin XiaoHang Construction Machinery Co., Ltd. helps distributors understand the critical differences between these models and outlines a procurement strategy for key spares.

Section 1: Key Technical Differences Affecting Part Sourcing

BP230 vs. BP210: What Matters for Procurement

While structurally similar, differences lie in gear ratio sets, clutch pack thickness, and electronic sensor configurations. Ordering a gear set or clutch pack based only on general model type is highly risky. Always use the full BOM number for verification.

Section 2: High-Wear Parts Checklist for BP Series

Critical Components to Keep in Stock

Key high-wear items for BP series often include: 1. Clutch Actuator Piston Kits: Due to constant start-stop cycles. 2. Main Hydraulic Filter Kits: Essential for maintaining clean hydraulic control. 3. Temperature Sensors: Prone to failure due to thermal cycling.

XiaoHang Technical Insight: We maintain a strong inventory of specialized BP series overhaul components. Our 20 years of technical support is available to help your technicians verify the pneumatic control systems and associated electronic components during installation.

Conclusion: Partner for BP Series Accuracy

Ensure your BP series parts procurement is accurate and cost-effective. Contact XiaoHang Machinery Co. today for competitive pricing and expert support on BP230 and BP210 spares.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

Torque Converter Failure in ZF Transmissions: Diagnosis, Causes, and Sourcing Reliable Replacement Units

Introduction: The Power Transfer Bridge

The torque converter is the essential hydraulic coupling between the engine and the ZF transmission. Its failure directly leads to catastrophic power loss, excessive heat generation, and low hydraulic pressure. Diagnosing a faulty converter is vital for avoiding unnecessary transmission overhauls.

This guide, informed by Tianjin XiaoHang Construction Machinery Co., Ltd.’s 20 years of expertise, provides a clear diagnostic pathway for torque converter failure and outlines the key considerations for sourcing high-quality replacement units.

Section 1: Telltale Symptoms of Torque Converter Failure

Recognizing the Signs Before Total Breakdown

Symptoms often include: 1. Overheating: A failing lock-up clutch generates excessive slip and heat. 2. Contaminated Fluid: Internal failure sheds metal debris into the hydraulic system. 3. Poor Acceleration/Stall Speed: The machine performs poorly, indicating low transfer efficiency.

Section 2: Procurement Strategy for Torque Converters

Quality and Compatibility are Non-Negotiable

Torque converters are complex assemblies. Sourcing requires strict adherence to the BOM number as the stalling speed and lock-up parameters are application-specific.

XiaoHang Technical Insight: Our 20 years of experience ensures we supply torque converters that are fully balanced and engineered to meet the exact stall specifications of your ZF model, preventing recurrence of overheating and slippage. We guarantee fast lead times for these critical, high-value components.

Conclusion: Secure Your Power Transfer

Do not risk machine performance with a substandard replacement. Partner with XiaoHang Machinery Co. to source reliable torque converters, protected by our technical support and competitive pricing.

Why Using the Wrong Transmission Fluid Kills Your ZF: Specifications, Consequences, and Sourcing Approved Alternatives

Substandard fluid directly contributes to major mechanical faults: 1. Seal Deterioration: Incorrect chemical composition attacks seal materials, leading to internal pressure leaks and slippage. 2. Clutch Pack Contamination: Poor quality oil lacks the thermal stability to protect friction plates, leading to rapid material degradation.

XiaoHang Technical Insight: Our 20 years of repair data confirm that low-quality fluid is often the hidden cause behind recurring solenoid and sensor failures, as contaminants are not suspended or filtered properly.

Section 3: Sourcing Reliable Fluid and Filter Kits

The XiaoHang Solution for Fluid and Filter Procurement

Tianjin XiaoHang Construction Machinery Co., Ltd. offers a complete solution:

- Verified Compatibility: We supply high-quality, ZF-compatible fluids and comprehensive filter kits that are technically approved by our experts.

- Fast Lead Times & Cost Advantage: Leveraging our China supply chain, we ensure fast lead times and competitive pricing for all fluid and filter packages.

Conclusion: Protect Your Investment with Verified Fluids

Ensure the longevity of your ZF transmissions by prioritizing technically compliant fluids and high-flow filters. Contact XiaoHang Machinery Co. today to secure verified fluid and filter kits, backed by our technical guarantee.

The Essential Role of Oil and Lubricant Specifications

Title: Why Using the Wrong Transmission Fluid Kills Your ZF: Specifications, Consequences, and Sourcing Approved Alternatives

Introduction: The Unsung Hero of Transmission Life

The fluid inside a ZF transmission is more than just oil; it is a highly engineered component responsible for lubrication, cooling, and hydraulic actuation. Using an incorrect or substandard fluid can instantly void warranties and lead to catastrophic component failure. For global procurement managers, the challenge is sourcing approved fluids or high-quality alternatives that maintain the required viscosity and thermal stability.

This guide, backed by Tianjin XiaoHang Construction Machinery Co., Ltd.’s 20 years of expertise, details the crucial specifications for ZF transmission fluid and offers reliable procurement strategies.

Section 1: Understanding ZF Fluid Specifications

The Difference Between Approved and Compliant Fluids

ZF transmissions demand fluids that meet specific performance standards. These standards dictate the viscosity index, shear stability, and anti-wear additives. Using non-approved fluids can cause excessive heat generation, foaming, and premature friction plate wear. Always verify the fluid specification against the transmission model’s Bill of Material (BOM) number.

Section 2: The Immediate Consequences of Using Substandard Fluid

When the Wrong Oil Goes Wrong

Substandard fluid directly contributes to major mechanical faults: 1. Seal Deterioration: Incorrect chemical composition attacks seal materials, leading to internal pressure leaks and slippage. 2. Clutch Pack Contamination: Poor quality oil lacks the thermal stability to protect friction plates, leading to rapid material degradation.

XiaoHang Technical Insight: Our 20 years of repair data confirm that low-quality fluid is often the hidden cause behind recurring solenoid and sensor failures, as contaminants are not suspended or filtered properly.

Section 3: Sourcing Reliable Fluid and Filter Kits

The XiaoHang Solution for Fluid and Filter Procurement

Tianjin XiaoHang Construction Machinery Co., Ltd. offers a complete solution:

- Verified Compatibility: We supply high-quality, ZF-compatible fluids and comprehensive filter kits that are technically approved by our experts.

- Fast Lead Times & Cost Advantage: Leveraging our China supply chain, we ensure fast lead times and competitive pricing for all fluid and filter packages.

Conclusion: Protect Your Investment with Verified Fluids

Ensure the longevity of your ZF transmissions by prioritizing technically compliant fluids and high-flow filters. Contact XiaoHang Machinery Co. today to secure verified fluid and filter kits, backed by our technical guarantee.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |