🚛 ZF Axle Maintenance: The Overlooked Critical Service for Mining Loaders

By TIANJIN XIAOHANG CONSTRUCTION MACHINERY CO.,LTD – Complete Drivetrain Solutions

🛑 It’s Not Just About the Gearbox

When people think “ZF,” they think transmissions. But for mining loaders and graders, the ZF Axles (AP and BP Series) bear the brunt of the load. Search data shows that “Axle overheating” and “Wet brake failure” are top concerns for mine operators in 2025 due to increased production demands.

I. The Critical Components: Wet Brakes & Seals

ZF axles use a sophisticated Wet Multi-Disc Brake system.

- The Failure Point: If the specialized axle oil isn’t changed, or if non-genuine friction discs are used, the braking material disintegrates. This debris travels through the axle, destroying the planetary gears.

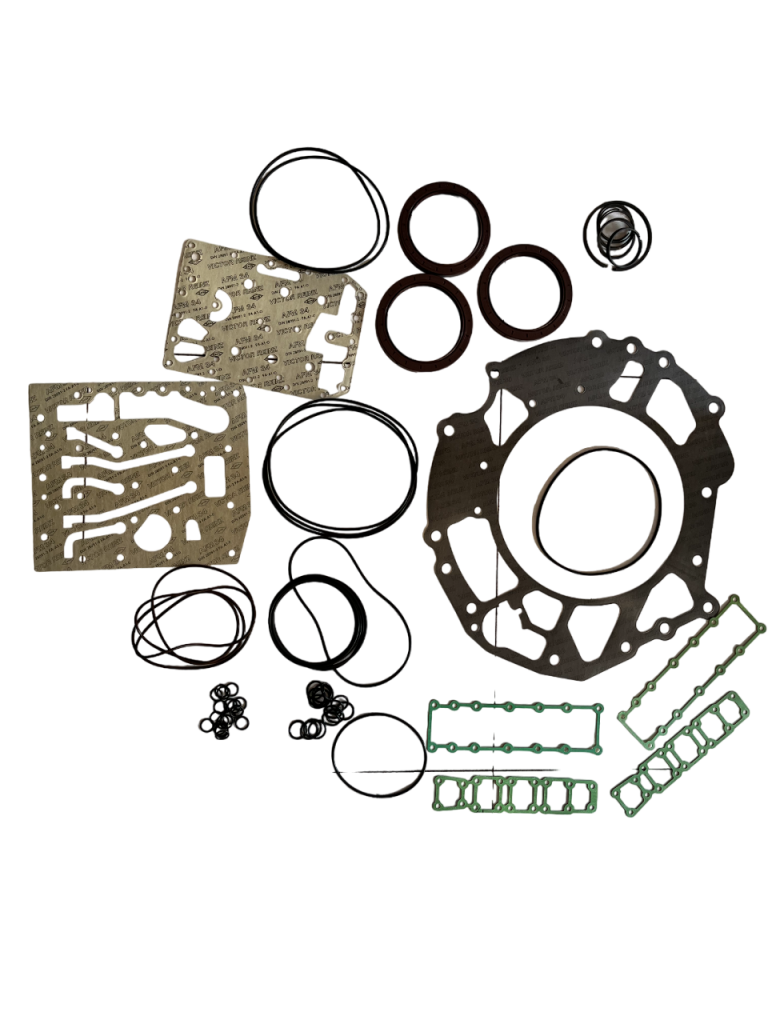

- Our Solution: We stock complete ZF Axle Overhaul Kits, including the specific friction discs designed for high-heat wet braking.

II. The “Wheel End” Vulnerability

The final drive (Wheel Hub) operates in the mud and dust.

- The Seal Risk: Once the Cassette Seal fails, dirt enters and oil leaves. The planetary gears will grind to dust within days.

- The Fix: We keep high-performance ZF Hub Seals in stock. Changing a seal today costs $50; changing a planetary gear set next week costs $5,000.

III. One Supplier, Full Drivetrain

Why split your orders? Tianjin Xiaohang is your one-stop source for both Transmission AND Axle parts. We verify compatibility between your gearbox output and axle input to ensure the whole drivetrain sings in harmony.

Keep your wheels turning. Source your heavy-duty axle spares from the authorized experts.

| Contact Us | Details |

| Sales Dept | TIANJIN XIAOHANG CONSTRUCTION MACHINERY CO.,LTD |

| 5858518@GMAIL.COM | |

| WhatsApp/Mobile | +86 15822863467 |