🏆 Case Study: How We Saved a South American Mine 3 Weeks of Downtime

By TIANJIN XIAOHANG CONSTRUCTION MACHINERY CO.,LTD – Real Solutions, Real Speed

📉 The Crisis

Location: A large copper mine in Peru.

Equipment: Critical production Loader (Komatsu WA series with ZF Driveline).

The Problem: Catastrophic failure of the ZF Front Axle (AP-400 series). The local dealer quoted 4 weeks for parts delivery from Europe. Every day the loader sat idle cost the mine $15,000 in lost production.

I. The Call to Tianjin Xiaohang

The mine’s procurement manager found us via Google and contacted Tianjin Linkworld Trading on a Tuesday.

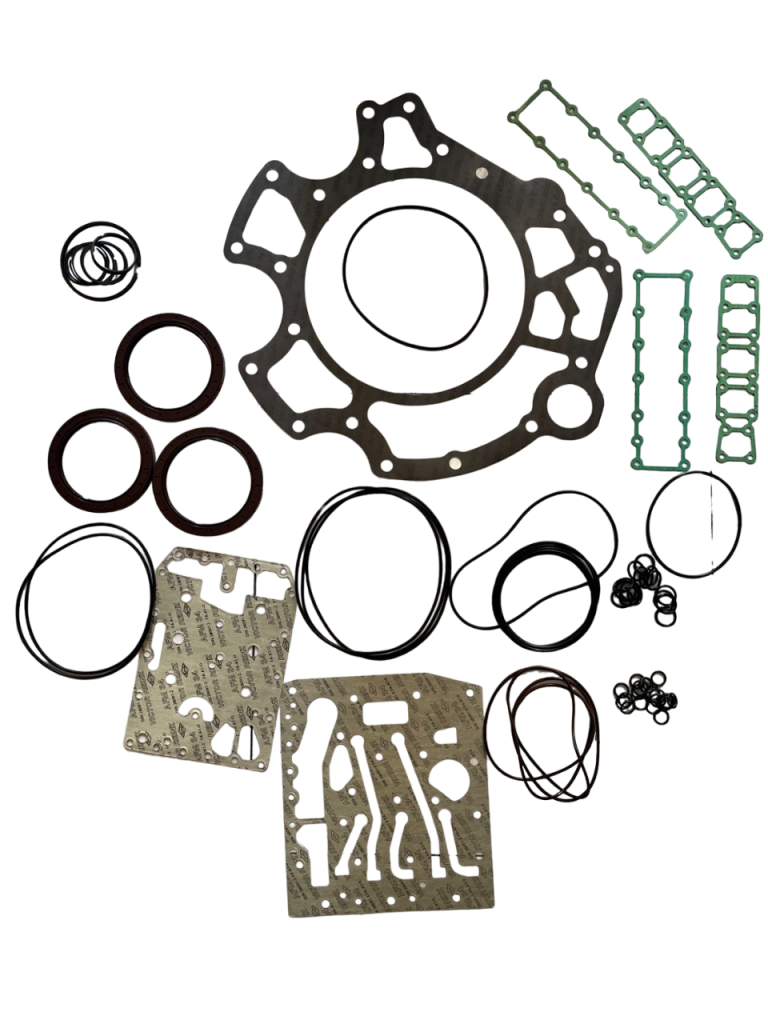

- The Challenge: They needed a complete Differential Gear Set and Heavy Duty Hub Seals—parts that are rarely stocked by standard dealers.

II. The Solution: Deep Inventory + Air Freight

Because we specialize in “Deep Inventory,” we checked our Tianjin warehouse.

- Status: In Stock. We didn’t need to order from a factory.

- Action: Within 6 hours, the parts were inspected, anti-rust treated, and packed in export-grade wooden crates.

III. The Result

- Wednesday: Cargo departed Beijing Capital Airport via DHL Express.

- Saturday: Parts cleared customs in Lima.

- Monday: Loader was back in operation.

Total Turnaround: 6 Days (vs. 4 Weeks quoted locally).

Total Savings: Over $300,000 in potential lost production.

IV. Why This Matters to You

You might not be a copper mine, but your downtime is just as painful. This case proves that sourcing from China (Tianjin Xiaohang) is often faster than sourcing locally, thanks to our stock levels and logistics speed.

Experience the difference. Next time you are told “it takes a month,” call us.

| Contact Us | Details |

| Emergency Parts | TIANJIN XIAOHANG CONSTRUCTION MACHINERY CO.,LTD |

| Global Logistics | TIANJIN LINKWORLD TRADING CO.LTD |

| 5858518@GMAIL.COM | |

| WhatsApp/Mobile | +86 15822863467 |