Introduction: The Hyundai-ZF Performance Standard

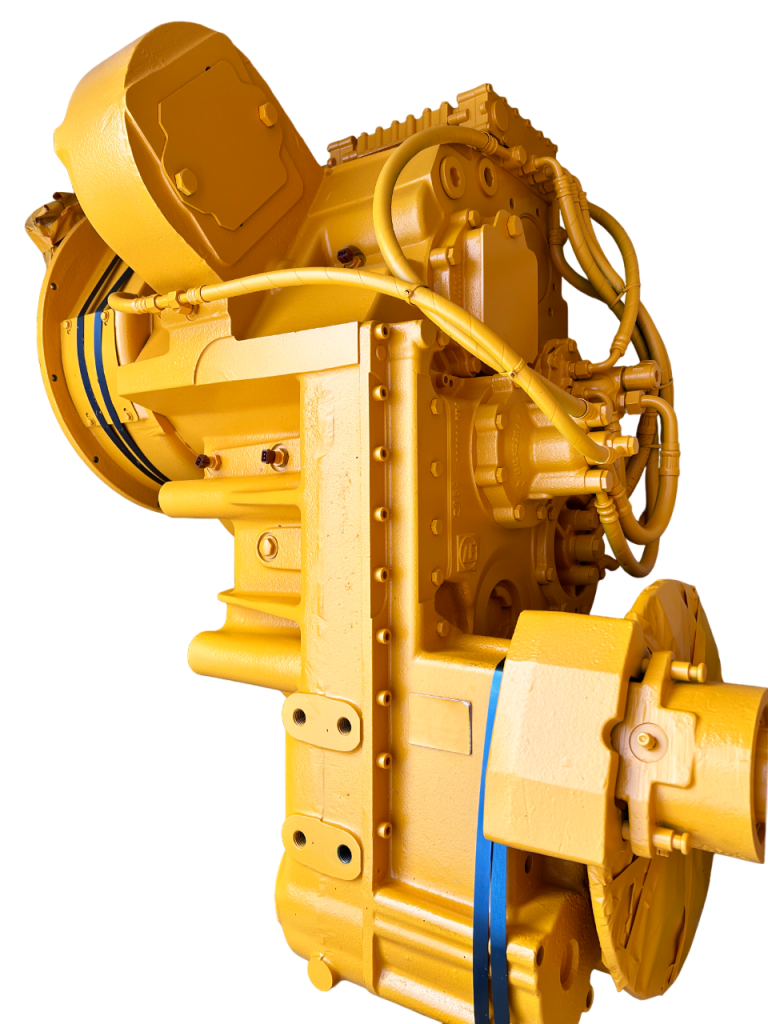

Hyundai Construction Equipment is a global brand known for its durable and powerful wheel loaders. To achieve this performance, Hyundai often integrates high-quality ZF transmissions (like the WG or Basicpower series) and ZF axles.

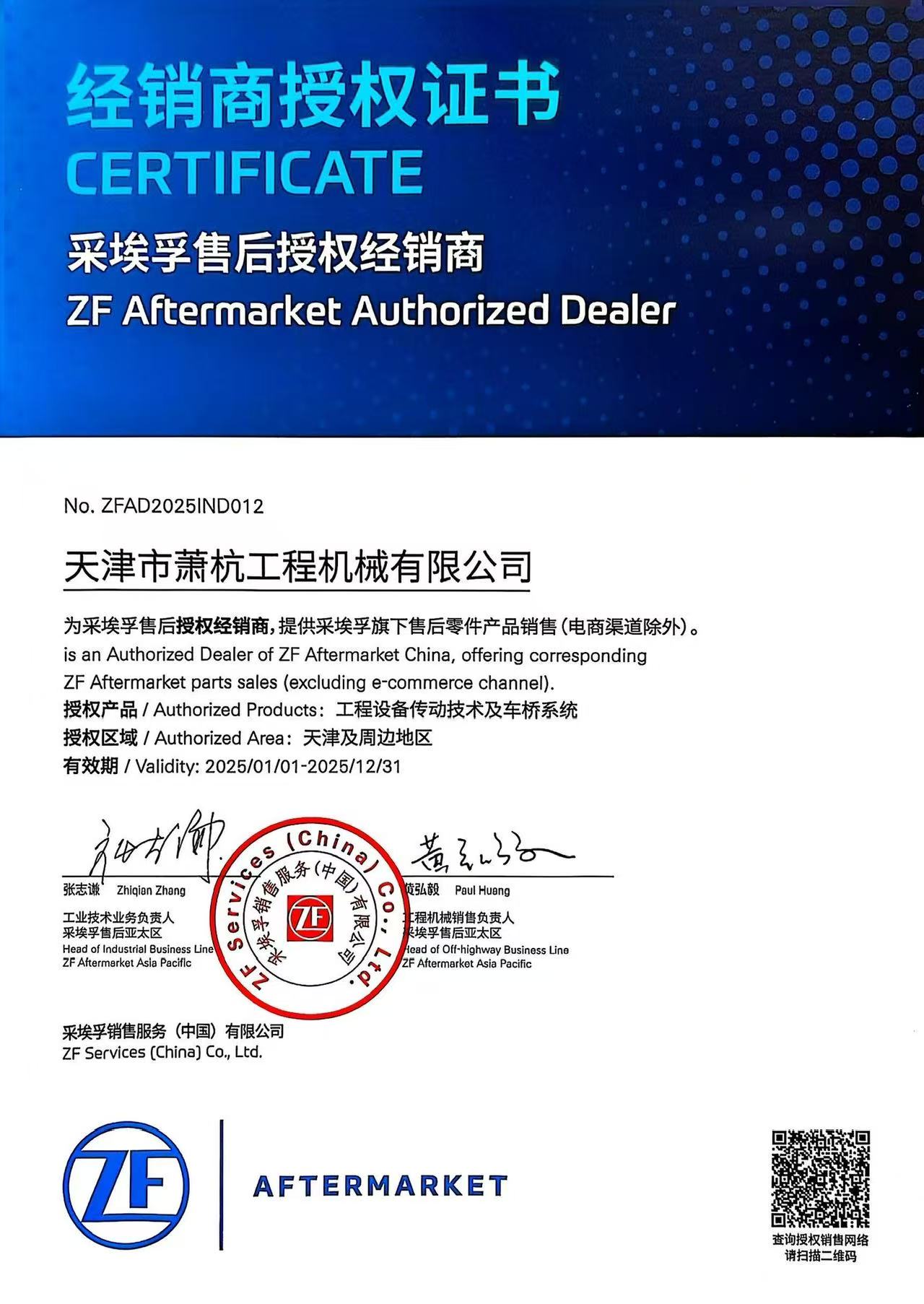

Servicing these machines requires a supplier who understands this specific integration. Tianjin XiaoHang Construction Machinery Co., Ltd. is a 20-year expert in sourcing and verifying parts for ZF-equipped Hyundai machinery.

Section 1: Identifying the ZF Components in Your Hyundai

Beyond the Hyundai Part Number

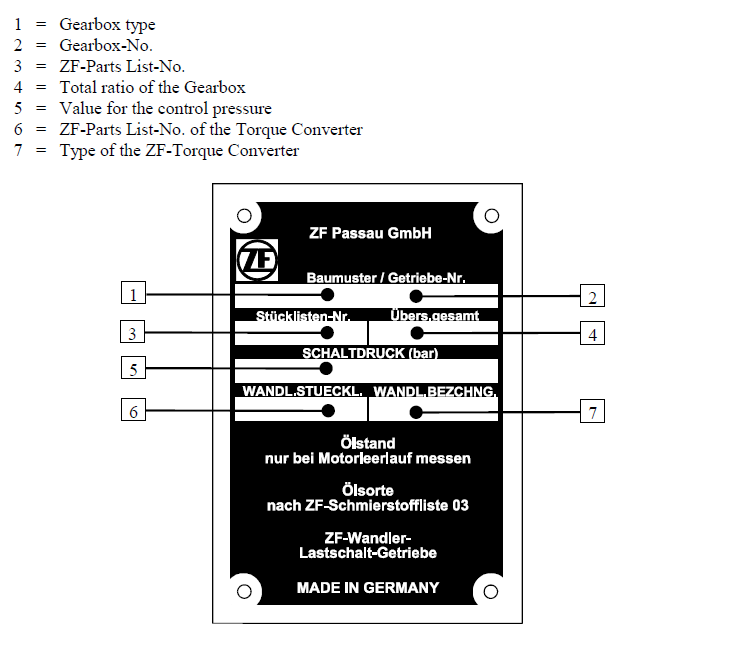

To source parts accurately and cost-effectively, you must find the ZF data plate on both the transmission and the axles. This plate will provide the Type (Model) and, most importantly, the Parts List No. (BOM). These numbers are essential for bypassing the high OEM markup and sourcing directly.

Section 2: Sourcing a Complete Driveline Solution

Common Parts for Hyundai Loaders

Based on our 20 years of experience, common high-wear items on ZF-equipped Hyundai loaders include:

- Transmission Clutch Packs: For forward/reverse (KV/KR or CF/CR).

- Electronic Sensors: Speed and temperature sensors for the transmission.

- Axle Components: Final drive planetary gears, differential parts, and wet brake discs for the ZF axles.

Section 3: The XiaoHang Advantage: Your OEM Expert

Technical Verification and Supply Chain Speed

Tianjin XiaoHang Construction Machinery Co., Ltd. specializes in supporting global distributors who service major OEMs.

- Technical Verification: We cross-reference your ZF BOM number to ensure 100% compatibility with the Hyundai application.

- Complete Sourcing: We supply parts for both the transmission and the axles, simplifying your procurement.

- Fast & Cost-Effective: Our China-based supply chain ensures fast lead times and competitive pricing.

Conclusion: Your Partner for Hyundai/ZF Spares

Trust XiaoHang Machinery Co. for verified, high-quality ZF spares for your Hyundai fleet.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| 5858518@gmail.com | |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

Introduction: The Difference Between a “Seller” and a “Partner”

Any supplier can sell you a part based on a part number. But what happens when the part doesn’t fix the problem? The most valuable asset a supplier can offer is not their inventory, but their experience.

Tianjin XiaoHang Construction Machinery Co., Ltd. is a 20-year technical service provider. We don’t just sell parts; we sell certainty and uptime.

Section 1: Before the Sale – Expert Diagnosis

Saving You Money by Preventing Misdiagnosis

Our 20 years of experience means we can help you before you order.

- Scenario: Your technician reports a “B1” (K1 Slippage) fault. A “seller” will sell you a K1 Repair Kit 4681.298.014.

- Our Expert Support: We ask, “Did you check the K1 solenoid (Y1 or Y4) resistance? Is it 19 $\Omega$? Did you check the main pressure at Test Point [K]? Is it 16+2 bar?”

- The Result: We help you discover the problem is just a cheap, faulty solenoid, saving you thousands on an unnecessary clutch overhaul.

Section 2: During the Sale – BOM Verification

Saving You Time by Ensuring Compatibility

Our experience means we know the pitfalls (like K-Clutch vs. C-Clutch, or EC4a vs. EST37A). We will verify your transmission’s BOM number to guarantee the part you order is compatible with your specific CASE or Liugong machine.

Section 3: After the Sale – Installation Support

Saving Your Reputation by Ensuring Correct Repair

Our support continues after delivery. We provide the critical knowledge for complex procedures, such as the AEB Clutch Calibration required after an oil change, ensuring the repair is done right.

Conclusion: Choose a Partner, Not Just a Parts Seller

Trust Tianjin XiaoHang Construction Machinery Co., Ltd. We are the technical partner that invests 20 years of expertise in your success.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| 5858518@gmail.com | |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

Introduction: Your Supply Chain is Your Competitive Advantage

For international distributors of ZF parts, your profit margin and customer satisfaction depend on two things: price and speed. Sourcing components from a supplier strategically located in a major logistics hub is a critical business advantage.

This guide explains why partnering with Tianjin XiaoHang Construction Machinery Co., Ltd., based in the major port city of Tianjin, streamlines your entire procurement process.

Section 1: The Tianjin Advantage – A Global Logistics Hub

Why Location Matters

Tianjin is one of the world’s largest ports and the primary gateway to Northern China.

- Direct Port Access: Our location means reduced inland freight costs and faster times from our warehouse to the vessel.

- Industrial Cluster: Tianjin is at the heart of China’s heavy machinery and manufacturing base. This proximity gives us direct access to the supply chain, reducing acquisition costs.

Section 2: The XiaoHang Advantage – More Than Just Location

Integrating Logistics with Expertise

Tianjin XiaoHang Construction Machinery Co., Ltd. leverages its location to offer:

- Fast Lead Times: Our strong inventory combined with port proximity means we can dispatch your orders (from clutch kits to complete torque converters) significantly faster than inland suppliers.

- Competitive Pricing: We pass our logistical and manufacturing-base savings directly to you.

- Consolidation: We are not just a ZF supplier. As our name implies, we are experts in Construction Machinery. We can help you consolidate other parts orders, saving you shipping costs.

Conclusion: A Smarter Supply Chain Partner

Don’t just buy a part; optimize your supply chain. Partner with Tianjin XiaoHang Construction Machinery Co., Ltd. to leverage the speed and cost advantages of a Tianjin-based expert.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| 5858518@gmail.com | |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

Introduction: Transparency and Trust in Sourcing

When you order a ZF 4BP210 Clutch Repair Kit, you need to know you are getting all the necessary components for a complete, reliable overhaul. Ordering a kit that is missing key parts can halt your repair and cost you time and money.

As a 20-year technical partner, Tianjin XiaoHang Construction Machinery Co., Ltd. believes in transparency. Here is a detailed breakdown of what you receive when you order the K1 Clutch Repair Kit 4681.298.014 (for BOM 4681.054.401).

Section 1: The Core Components (Friction and Steel)

The Parts That Handle the Torque

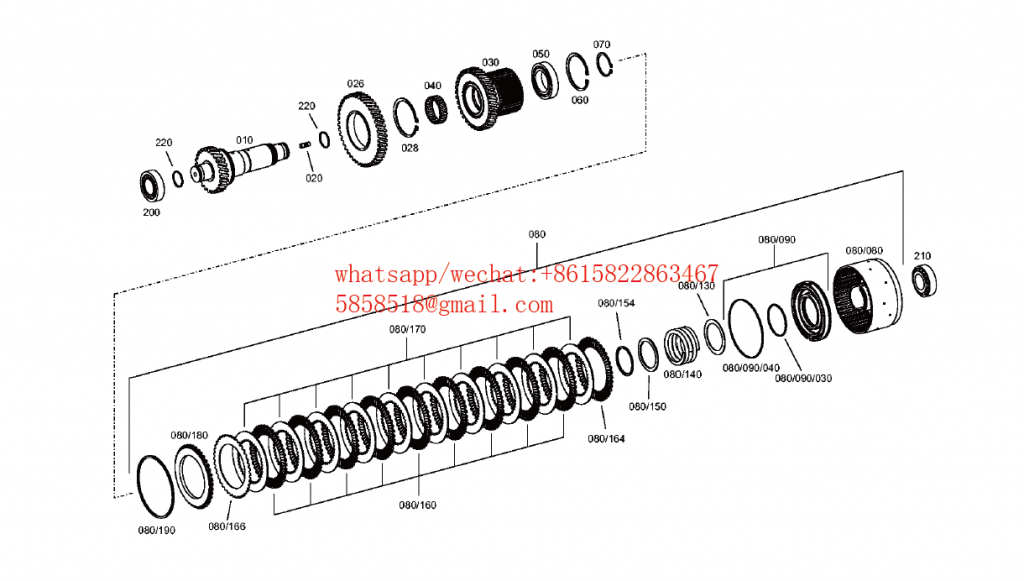

This kit is for the K1 Clutch (Assembly 4681.171.002). It contains the full stack of high-wear components:

- Friction Discs (Internal): A full set of 9x Inner Clutch Disks (Part No. 0501.316.591)

- Steel Discs (External): A full set of 8x Discs (Part No. 0501.212.372)

- Outer Discs: Includes 2x Outer Clutch Disks (Part No. 0501.212.373)

- End Shim: 1x End Shim (Part No. 0501.340.819)

- Snap Rings: A full set of snap rings (e.g., 0730.308.095 to .109) to set the correct clearance.

Section 2: The Essential Sealing Components

Stopping the Leaks That Cause Slippage

A clutch repair fails if the hydraulic pressure leaks. This kit includes the critical seals for the K1 Piston (Piston 4681.275.013):

- Inner Piston O-Ring: 1x O-Ring 0634.313.643

- Outer Piston O-Ring: 1x O-Ring 0634.313.719

Section 3: The XiaoHang Machinery Co. Guarantee

Complete, Verified, and Ready to Ship

When you source from Tianjin XiaoHang Construction Machinery Co., Ltd., we guarantee that the repair kit you receive is complete, dimensionally accurate, and made from high-specification materials that can handle the 16+2 bar system pressure. Our strong inventory and fast lead times mean you get this complete kit quickly.

Conclusion: Order with Confidence

Know exactly what you are buying. Contact XiaoHang Machinery Co. for complete, verified ZF repair kits.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| 5858518@gmail.com | |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

Introduction: A High-Urgency Diagnostic Guide

One of the most stressful field scenarios is a machine that “won’t move.” A ZF 4BP230 with a “No Drive” or “No Gear Engagement” condition can be caused by several issues. Starting your diagnosis in the wrong place wastes time and money.

As a 20-year transmission repair expert, Tianjin XiaoHang Construction Machinery Co., Ltd. provides this logical diagnostic flow to help technicians quickly find the root cause.

Section 1: Step 1 – Check the Hydraulic Heart (The Pump)

Is There Pressure?

Before you blame the clutches, check the system’s lifeblood. The 4BP230 requires 16+2 bar of main system pressure to function.

- Action: Connect a gauge to the main pressure Test Point [K] (M10x1) on the control valve body.

- Result (A): If pressure is low or zero, your problem is likely the Oil Pump (e.g., 0750.109.325), a clogged suction filter, or low oil.

- Result (B): If pressure is 16+2 bar, the pump is working. Move to Step 2.

Section 2: Step 2 – Check the Electronic Brain (Solenoids & TCU)

Is the System Commanding the Shift?

If pressure is good, the TCU may not be sending the signal, or the solenoid isn’t acting on it.

- Action 1: Check for fault codes. A sensor fault (like 3E) can stop shifts.

- Action 2: Check the proportional solenoids (Y1-Y6). Disconnect the solenoid for the problem gear and check its resistance. It should be 19 $\Omega$ (Ohms).

- Result: If the resistance is open or shorted, the solenoid is dead.

Section 3: Step 3 – Check the Mechanical Muscle (The Clutch)

Is the Clutch Pack Itself Worn Out?

If pressure is good and electronics are working, the problem is mechanical.

- Action: This is likely a “B-Hex” slippage fault (B1-B6).

- Result: The friction discs inside the clutch pack (e.g., K1 or KV) are worn out and can no longer hold the torque. This requires a full clutch repair kit.

Conclusion: From Diagnosis to Delivery, Fast

Tianjin XiaoHang Construction Machinery Co., Ltd. supports you at every step. We can help you diagnose the fault and have the replacement part—whether it’s the Oil Pump, a 19 $\Omega$ Solenoid, or a Clutch Repair Kit—in stock and ready for fast delivery from our China-based inventory.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| 5858518@gmail.com | |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

Introduction: From Reactive Repair to Proactive Uptime

Waiting for a fault code like “BA” (Filter Clogged) or “B1” (Clutch Slippage) is the most expensive way to maintain your ZF 4BP230 transmission. A proactive maintenance schedule, based on official ZF guidelines, prevents these failures before they happen.

As a 20-year technical service partner, Tianjin XiaoHang Construction Machinery Co., Ltd. provides this expert schedule for fleet managers.

Section 1: The XiaoHang Recommended Maintenance Schedule

Follow These Intervals to Maximize Component Life

Daily (Pre-Operation Check):

- Check for any visible fluid leaks around seals and hoses.

- Ensure the transmission engages smoothly into Forward and Reverse.

First 100 Operating Hours (Critical First Service):

- Action: Perform the first complete oil and filter change.

- Reason: To remove initial break-in contaminants.

- Required Parts: Approved TE-ML 03 Oil and a high-quality filter (e.g., 0501.298.690).

Every 1000 Operating Hours (or 12 Months):

- Action: Perform a complete oil and filter change.

- Reason: Prevents oil degradation and stops the “BA” (Filter Clogged) fault.

- CRITICAL STEP: Perform an AEB (Clutch Calibration) using a ZF Testman tool. This recalibrates the clutch bite point to prevent slippage.

Section 2: How This Schedule Prevents “B-Hex” Faults

The Connection Between Maintenance and Faults

The “B-Hex” codes (B1-B6) are caused by clutch slippage. Slippage is most often caused by:

- Contaminated Oil: Old fluid loses its friction properties.

- Low Pressure: A clogged filter (BA fault) starves the pump, reducing the 16+2 bar pressure needed to hold the clutches.

By following the 1000-hour service interval, you ensure the oil is clean and the pressure is high, directly preventing the conditions that cause slippage.

Conclusion: Your Partner in Proactive Maintenance

Tianjin XiaoHang Construction Machinery Co., Ltd. is your partner for maximizing uptime. We supply the complete, verified service kits (filters and oil) and provide the 20 years of technical expertise to support your maintenance schedule.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| 5858518@gmail.com | |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

Introduction: A High-Value Sourcing Question

This is one of the most common and highest-risk questions in the global parts market: “I have a CASE loader and a Liugong loader, both with ZF transmissions. Can I use the same repair kits?”

The answer is NO. You cannot assume compatibility. As a 20-year specialist in ZF integrations, Tianjin XiaoHang Construction Machinery Co., Ltd. explains why.

Section 1: The “BOM” (Bill of Material) is King

Why “4BP230” is Not Enough Information

While CASE, Liugong, and XCMG all use ZF transmissions (like the 4BP230 or 4WG210), they order them from ZF with unique configurations. Each configuration has a different BOM (Parts List No.), found on the transmission’s data plate.

These differences are not cosmetic. A BOM for a Liugong machine might specify:

- Different electronic controls (e.g., EC4a TCU)

- Different clutch pack dimensions (e.g., C-Clutches vs. K-Clutches)

- Different gear ratios or output flanges.

A BOM for a CASE machine may use completely different components (e.g., EST37A TCU).

Section 2: The XHC Verification Service

We Prevent Your Sourcing Errors

Tianjin XiaoHang Construction Machinery Co., Ltd. is one of China’s most established ZF transmission experts. Our 20 years of experience is built on understanding these complex OEM differences.

- Do not order parts based on the machine’s brand.

- Do send us the ZF BOM number from the transmission plate.

Our technical team will cross-reference your BOM and guarantee that the clutch kits, sensors, and valves you receive are 100% compatible with your specific machine, whether it’s a CASE, Liugong, or XCMG.

Conclusion: The Expert Partner for All OEMs

Stop risking costly returns. Use the supplier that understands the technical differences between global OEMs. Contact XiaoHang Machinery Co. to verify your BOM and source the correct part, fast.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| 5858518@gmail.com | |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

Introduction: The Procurement Manager’s Dilemma

When sourcing ZF electronic parts, the temptation to choose the cheapest available sensor is high. But for a high-precision system like the ZF 4BP230, a “cheap” sensor is often the most expensive part you can buy.

As a 20-year technical authority, Tianjin XiaoHang Construction Machinery Co., Ltd. explains the hidden costs of using non-verified electronic components.

Section 1: The Sensor’s Hidden Job: Precision

Why 1050 Ω (Ohms) Matters

A ZF speed sensor (like 0501.328.675) isn’t just a simple switch. It’s an inductive sensor that must provide a precise signal. ZF technical data specifies its resistance must be 1050 $\Omega$ $\pm$10%. A cheap, non-verified sensor may have a resistance of 900 $\Omega$ or 1200 $\Omega$.

Similarly, a proportional solenoid valve must have a precise resistance of 19 $\Omega$ to correctly interpret the TCU’s 100-500mA current.

Section 2: The Chain Reaction of Failure

How the $50 Part Kills the Transmission

- Bad Data: The “cheap” sensor with incorrect resistance (e.g., 1200 $\Omega$) sends a faulty speed signal to the TCU.

- Incorrect Calculation: The TCU miscalculates the shift timing, applying pressure to the clutch pack at the wrong moment.

- Clutch Slippage: This incorrect timing causes the clutch to slip, generating immense heat.

- The Fault Code: The operator gets a ‘B-Hex’ fault code (e.g., B1 Clutch K1 Slippage), but the root cause wasn’t the clutch; it was the cheap sensor.

- The $5,000 Repair: By the time the slippage is noticed, the friction discs are destroyed, requiring a full clutch pack overhaul.

Section 3: The XiaoHang Machinery Co. Quality Guarantee

Verified Parts. No Exceptions.

We at Tianjin XiaoHang Construction Machinery Co., Ltd. use our 20 years of repair expertise to source and verify our aftermarket parts. We guarantee that the sensors and solenoids we sell meet the exact ZF electrical specifications (1050 $\Omega$, 19 $\Omega$). We protect your machinery by ensuring our parts send the correct data.

Conclusion: Invest in Certainty, Not Chance

Don’t risk a $5,000 overhaul to save $50. Source your verified, high-quality ZF electronic components from Tianjin XiaoHang Construction Machinery Co., Ltd.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| 5858518@gmail.com | |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

Introduction: Maintenance That Prevents Failure

Changing the oil and filter on a ZF 4BP230 transmission is the most critical maintenance task. However, simply replacing the parts is not enough. Failure to perform the electronic AEB (Clutch Calibration) afterward is a common mistake that leads to harsh shifting and premature clutch wear.

As a 20-year technical service partner, Tianjin XiaoHang Construction Machinery Co., Ltd. provides this expert field guide for technicians.

Section 1: The 5-Step Filter and Calibration Process

Do It Right, Once

- Drain and Inspect: Drain the old fluid. Inspect the magnetic drain plug (M38X1.5) for excessive metal debris—a key warning sign.

- Replace the Filter: Remove the old filter. We recommend a verified, high-quality replacement, such as 0501.298.690 (for BOM 4681.084.018). Always apply a thin layer of clean oil to the new filter’s gasket before installing.

- Refill with Correct Fluid: Refill the system with oil meeting the ZF TE-ML 03 specification.

- Warm Up: Run the machine, checking the oil level (as per Article 38), until the transmission reaches operating temperature (approx. 80°C).

- Perform AEB Calibration: This is the critical step. Using a ZF Testman diagnostic tool or the AEB Starter tool, initiate the clutch calibration. The TCU will automatically relearn the precise filling times for each clutch (K1-K4, KV, KR).

Section 2: Why AEB Calibration is Not Optional

The XiaoHang Technical Explanation

The AEB calibration compensates for tiny manufacturing differences in solenoids and the natural wear of clutch discs. After an oil change, the new fluid’s viscosity requires the TCU to relearn this “bite point.” Skipping this step causes the TCU to use old, incorrect data, resulting in shift shock and component damage.

Conclusion: We Provide the Parts and the Knowledge

Tianjin XiaoHang Construction Machinery Co., Ltd. doesn’t just sell you the filter; we provide the 20 years of technical expertise to ensure the job is done right. We supply the correct filters, fluids, and the technical support you need for diagnostics like the AEB calibration.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| 5858518@gmail.com | |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

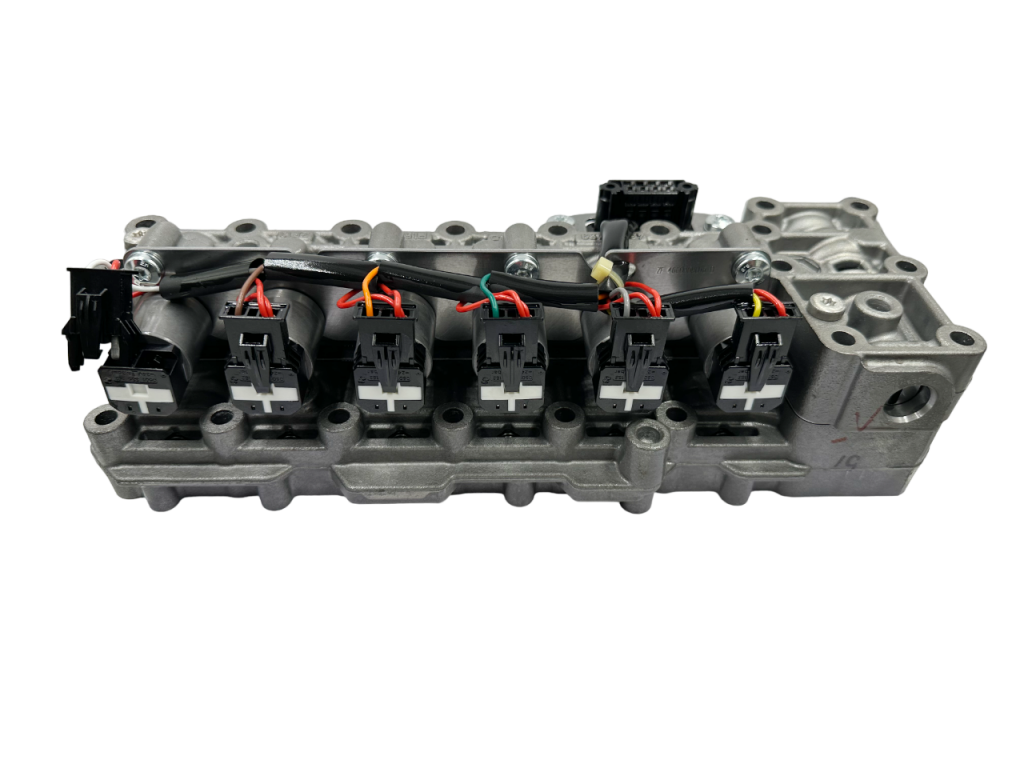

Critical Spares for the ZF 4 BP 230 SHIFT SYSTEM: Solenoids, Sensors, and the Duct Plate

Introduction: The Shift System’s Nerve Center

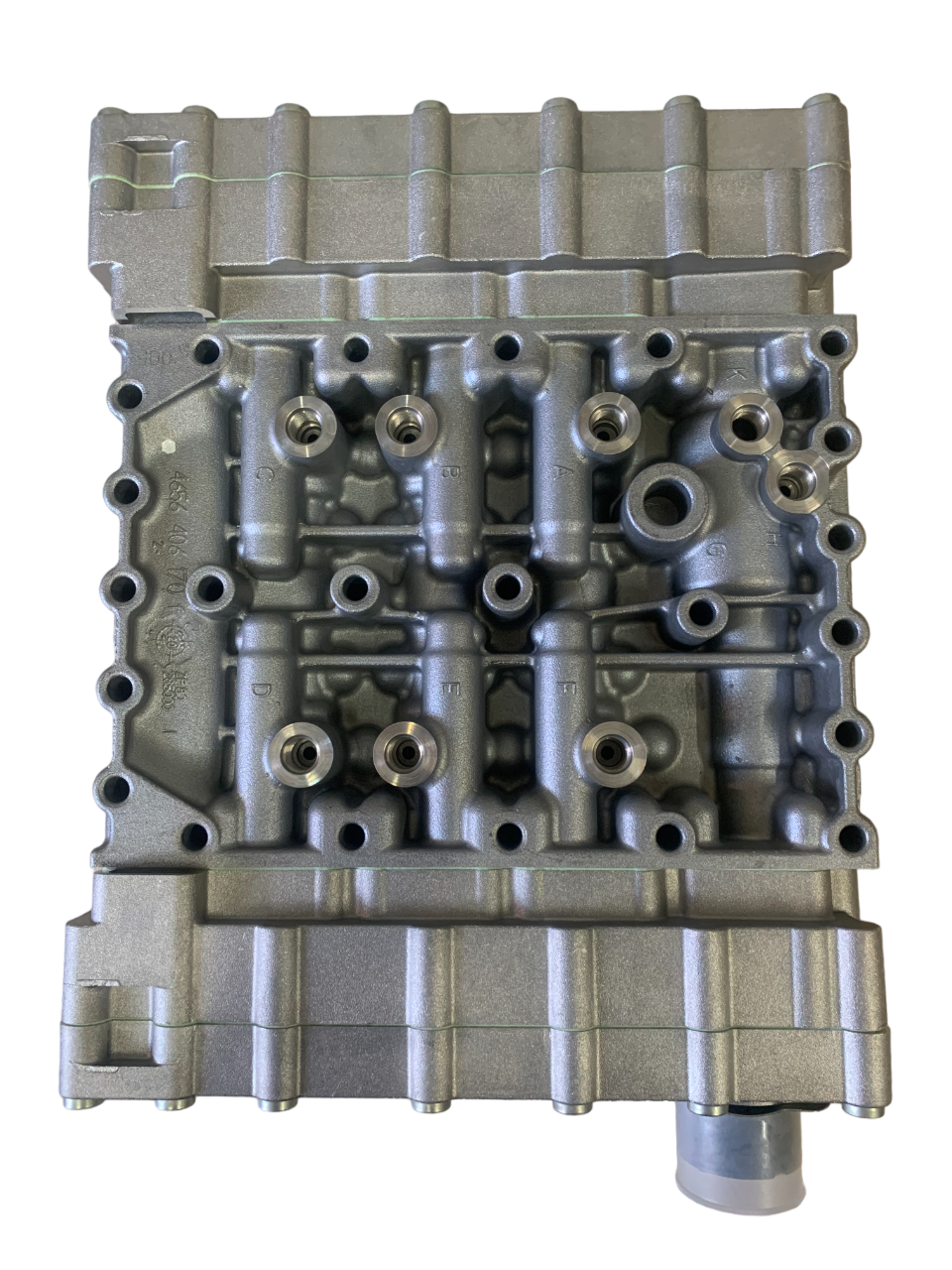

The SHIFT SYSTEM (Assembly 4681.106.005) contains the Hydraulic Control Unit (HCU) and the critical electronic and sealing components that manage gear engagement. Failures here often result in erratic shifting or total drive loss.

This guide focuses on the procurement of high-precision components for the SHIFT SYSTEM, including the Temperature Sensor 0501.322.532 and various screw plugs and O-rings.

Section 1: Key Components for SHIFT SYSTEM Integrity

Precision Parts Checklist

The SHIFT SYSTEM is protected by various seals and contains critical electronic sensors. Key parts include:

- GASKET 4681.306.010 and DUCT PLATE 4681.306.011: Essential for hydraulic circuit integrity.

- TEMPERATURE SENSOR 0501.322.532: Provides vital oil temperature data to the TCU.

- SCREW PLUGS 4475.280.016 and O-RINGS: Used for sealing and pressure test points.

Section 2: Sourcing Sensors and Sealing Assurance

The XiaoHang Technical Guarantee

Electronic components like the Temperature Sensor 0501.322.532 must be verified for compatibility. Our 20 years of expertise guarantees accurate cross-referencing. For sealing, we supply all necessary O-rings (e.g., 11X2 and 13X2) to maintain the required hydraulic pressure.

Section 3: Fast Supply for Complex Assemblies

XiaoHang Machinery Co. minimizes downtime on complex shift system repairs. We leverage our China supply chain for fast lead times and competitive pricing on both major components (like the valve block) and all necessary sealing kits.

Conclusion: Ensure Shift Precision with XiaoHang

For verified ZF 4 BP 230 SHIFT SYSTEM spares, trust the technical precision and supply speed of Tianjin XiaoHang Construction Machinery Co., Ltd.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| 5858518@gmail.com | |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |