Introduction: The Final Connection

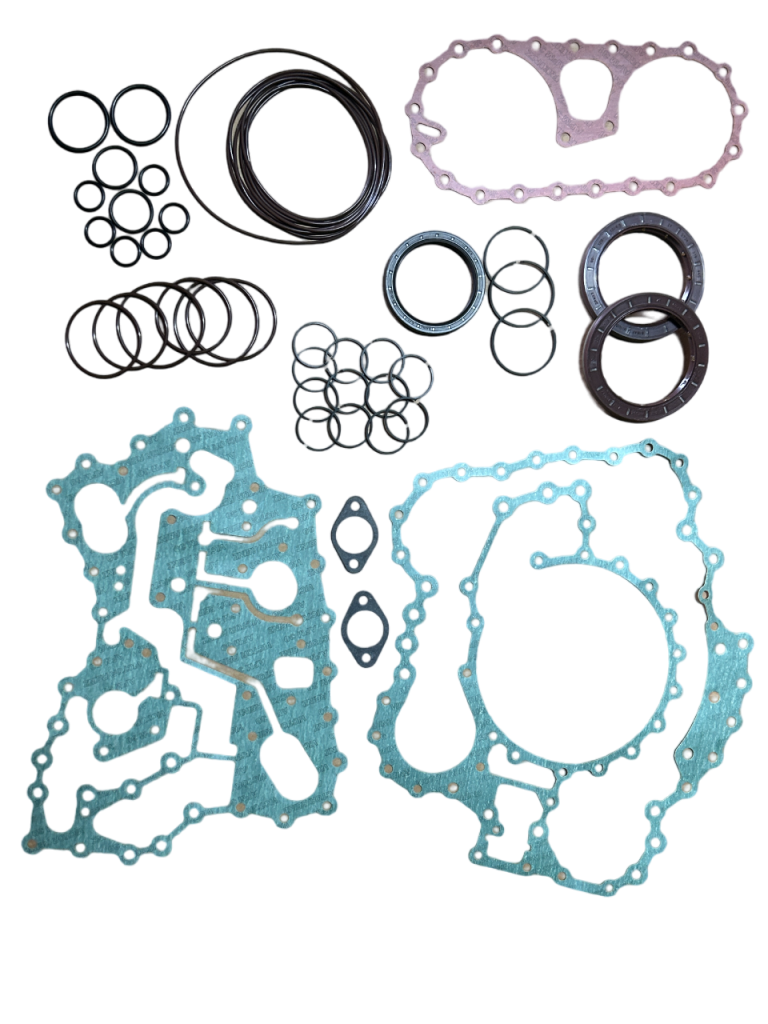

The Output Flange is the final component in the ZF transmission, transferring power to the driveline. Ensuring the integrity of the output flange and its seals is vital, as a leak here compromises the entire transmission.

This guide focuses on sourcing the OUTPUT FLANGE 4644.303.547 (used in some 4WG200 models) and the associated SHAFT SEAL 0750.111.116.

Section 1: The Integrity of the Output Flange Assembly

Sourcing Flanges and Seals

The Output Flange assembly requires specific sealing components25:

- OUTPUT FLANGE 4644.303.547: Must be sourced to meet the exact load rating and spline specifications (e.g., Z=42).

- SHAFT SEAL 0750.111.116: A critical high-wear seal (90x120x13).

- O-RING 0634.303.466: Essential for sealing the flange cover.

Section 2: The XiaoHang Guarantee on Seals and Flanges

Precision and Durability

XiaoHang Machinery Co.’s 20 years of expertise ensures the output flanges we supply meet rigorous load-rating standards. Crucially, we guarantee the material quality and dimensional accuracy of all associated SHAFT SEALS and O-RINGS to prevent costly external leaks.

Conclusion: Secure Your Final Connection

Ensure driveline integrity with verified ZF output flanges and seal kits. Contact XiaoHang Machinery Co. today for competitive pricing and expert supply.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| 5858518@gmail.com | |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

Introduction: The Supplier’s Most Valuable Asset

In the age of online sourcing, any company can claim to have parts in stock. But when faced with a complex ZF fault—such as intermittent solenoid errors or unexpected clutch failure—inventory alone is useless. Experience is your most valuable asset.

Tianjin XiaoHang Construction Machinery Co., Ltd.‘s 20 years of repair and field service is the true core of our value proposition.

Section 1: Experience in Diagnosis (Before the Sale)

Preventing Misdiagnosis is Profit

Our technical team can interpret complex fault scenarios. We know that a low 16+2 bar pressure reading might not mean a pump failure; it could be the PRESSURE REGULATOR stuck due to contamination. Our guidance prevents you from unnecessarily replacing expensive, functional parts.

Section 2: Experience in BOM Verification (During the Sale)

Guaranteeing Compatibility by Knowing the History

We specialize in the ZF components used by Chinese OEMs (Liugong, XCMG) and know the critical distinctions between K-Clutch and C-Clutch designs. Our experience ensures that when you provide the BOM, we confirm the exact component variant, preventing the three major costs of inaccurate sourcing: freight, labor, and downtime.

Conclusion: Trust Experience, Trust XiaoHang

Don’t trust your business to a novice supplier. Partner with Tianjin XiaoHang Construction Machinery Co., Ltd., the ZF expert whose 20 years of technical expertise is your guarantee of accurate supply and reliable service.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| 5858518@gmail.com | |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

Introduction: The Foundation of the Driveline

Repairing major ZF failures often involves replacing structural components like the TRANSMISSION HOUSING or internal axle parts. These are high-value, structural parts that must be sourced with absolute confidence in their casting quality and dimensional accuracy.

This guide focuses on the procurement of large structural and housing parts for the ZF driveline.

Section 1: Key Structural and Housing Components

High-Value, High-Integrity Parts

We focus on key assemblies:

- TRANSMISSION HOUSING (e.g., 4644.101.249 for 4WG200): The main casing. This is a crucial component that houses the entire gear system.

- DIFFERENTIAL HOUSING (e.g., for Assembly 4644.104.016): The structural base for the axle gear set.

- SEALING CAP 4642.301.106 and SCREW PLUG 4475.280.011: Essential for sealing large oil cavities.

Section 2: The XiaoHang Quality Assurance on Castings

Guaranteed Dimensional Accuracy

Sourcing large housing components requires verification that the castings meet original specifications. XiaoHang Machinery Co.’s 20 years of expertise guarantees:

- Dimensional Accuracy: Our parts ensure the correct alignment of all internal shafts and bearings.

- Material Quality: We ensure the housing components meet the required strength and heat dissipation characteristics.

Conclusion: Your Partner for Structural Components

Trust Tianjin XiaoHang Construction Machinery Co., Ltd. for verified ZF housing and structural components, providing the foundation for a reliable repair.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| 5858518@gmail.com | |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd |

Introduction: Precision Beyond the Bearing

When performing a full transmission overhaul (e.g., on the 4WG200 or 6WG310), simply installing new TAPERED ROLLER BEARINGS is not enough. The ultimate reliability of the repair depends on setting the precise Bearing Preload or Axle End Play. This is controlled by using SHIM RINGS.

This highly technical guide from Tianjin XiaoHang Construction Machinery Co., Ltd. focuses on the procurement of the specific ZF shim rings required for correct bearing adjustment.

Section 1: Why Shims are Essential for Bearing Life

The Difference Between Repair and Disaster

Shims (e.g., SHIM RING 0730.004.042) are thin washers with specific thicknesses (e.g., 1.0mm, 1.2mm, 1.4mm) used to adjust the axial play of the bearing assemblies.

- Too Loose: Excessive play causes vibration, noise, and rapid failure of the new bearings.

- Too Tight: Excessive preload causes overheating and immediate destruction of the bearing.

Section 2: Sourcing the Right Shim Rings

Precision Sourcing Strategy

Bearings like the INDUCTIVE SENSOR 0501.317.160 require precise shimming. You must maintain a comprehensive inventory of shim rings in fine increments (e.g., 0.2mm, 0.3mm, 0.5mm increments) to achieve the correct preload.

XiaoHang Machinery Co. supplies all the specific ZF shim part numbers required for various ZF axle and transmission assemblies. Our 20 years of experience ensures we understand the precise technical application of each shim.

Conclusion: Precision Ensures Longevity

Protect your overhaul investment. Source your high-precision SHIM RINGS from Tianjin XiaoHang Construction Machinery Co., Ltd. to guarantee correct bearing preload and maximum component life.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| 5858518@gmail.com | |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

Introduction: Decoding the “BA” Fault

The “BA” fault code or the FILTER CLOGGED ALARM on ZF transmissions is a direct warning to the operator that the fine filter (pressure filter) is blocked. Ignoring this can cause the 16+2 bar system pressure to drop, resulting in clutch slippage and pump damage.

This technical guide, informed by Tianjin XiaoHang Construction Machinery Co., Ltd.’s 20 years of expertise, explains this fault and the necessary parts procurement.

Section 1: The Alarm Mechanism and Diagnosis

The Role of the Pressure Drop Switch

The alarm is triggered by the Pressure Drop Switch (PRES. DROP SWITCH) , which is often a CLOSING SWITCH that closes the circuit when the pressure differential across the filter (e.g., 0750.131.053) exceeds a limit.

- Action: The first step is always to replace the filter immediately. If the alarm persists, the fault is likely the TAPPET SWITCH 0501.210.966 or its wiring.

Section 2: Sourcing Verified Filter Kits and Sensors

The XiaoHang Quality Standard

When addressing the “BA” alarm, two parts must be sourced correctly:

- The Filter: Must be a high-quality replacement filter (e.g., 0501.333.764 for 6WG191) that guarantees optimal flow.

- The Switch: If the alarm is persistent, the TAPPET SWITCH 0501.210.966 must be replaced to ensure the alarm accurately reports the status.

Conclusion: Immediate Action is Required

Don’t ignore the “BA” code. Trust XiaoHang Machinery Co. to supply the correct filter and pressure switch components, ensuring rapid maintenance and technical integrity.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| 5858518@gmail.com | |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

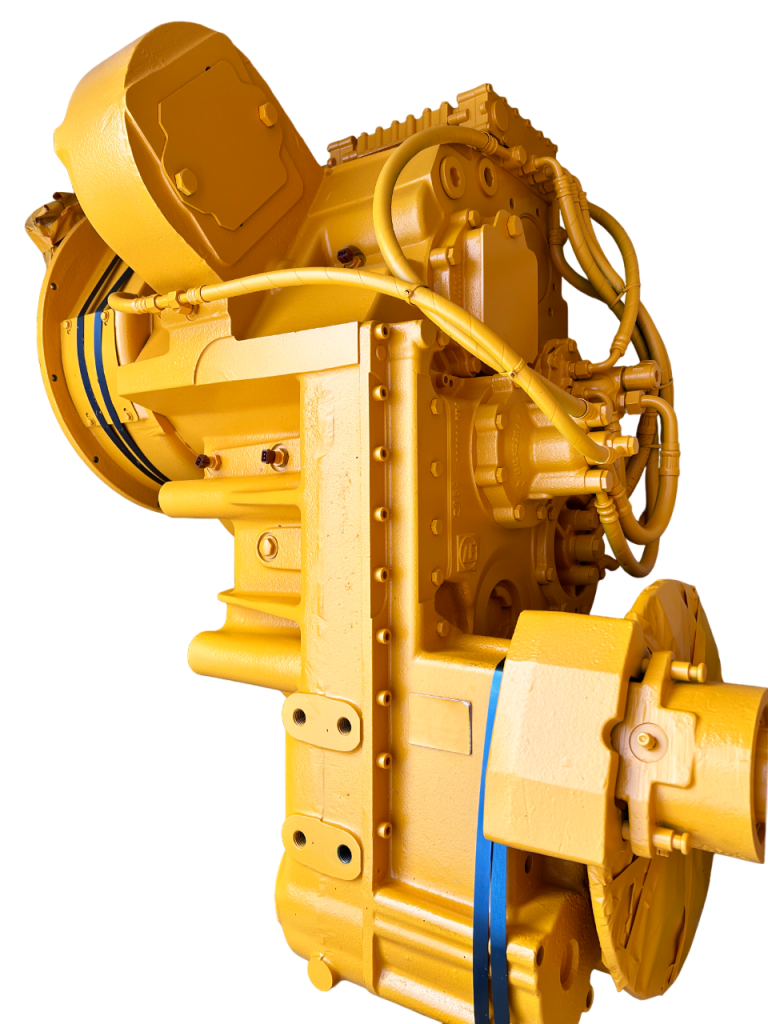

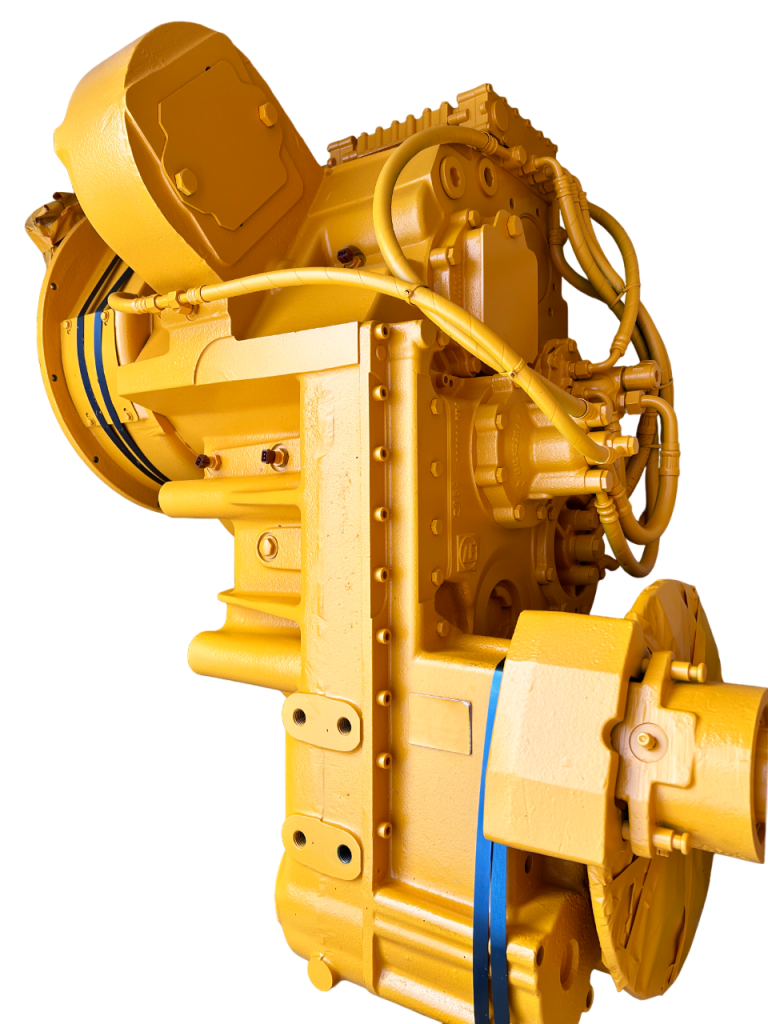

Introduction: Drivetrain Beyond the Transmission

For full maintenance and service capability, distributors must look beyond the transmission to the integrated ZF Axle Systems. Failure in the differential assembly compromises machine traction and drivability.

This guide from Tianjin XiaoHang Construction Machinery Co., Ltd. helps you stock the critical parts for ZF axle systems, including the high-stress PLANETARY GEARS.

Section 1: Key Components in the ZF Differential

Inside the Differential Housing

The ZF differential assembly (4644.104.016) is responsible for distributing torque. Key components that require service and replacement are:

- PLANETARY GEAR 4644.304.049: The core rotating gear (Quantity 6).

- CYLINDER ROLLER BEARING 0735.470.232: High-precision bearing that supports the planetary gear sets.

- SHAFT SEAL 0750.111.116: Critical external seal (90x120x13).

Section 2: The Importance of Gear Metallurgy

Quality Sourcing for High Torque

The PLANETARY GEARS 4644.304.049 and the supporting bearings must withstand immense, continuous torque loads. XiaoHang Machinery Co.’s 20 years of repair expertise ensures we supply components that meet the exact hardness and material specifications required by ZF, preventing premature catastrophic failure.

Section 3: Sourcing for a Complete Driveline Service

The XiaoHang Advantage

XiaoHang Machinery Co. offers a simplified, single-source solution. We supply both the transmission overhaul kits and essential ZF Axle components (including the differential parts) with fast lead times and competitive pricing.

Conclusion: Offer Total Drivetrain Reliability

Expand your service offerings. Contact XiaoHang Machinery Co. today to secure verified ZF differential and axle components.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| 5858518@gmail.com | |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

Introduction: Safety-Critical Components

In many large vehicles equipped with the ZF 6WG310 (BOM 4646.076.013), an Emergency Steering Pump is mandated for safety. This pump, often a PISTON PUMP 0501.223.162, ensures steering functionality if the main engine or hydraulic pump fails.

Procuring this safety-critical EMERGENCY STEERING PUMP (Assembly 4646.137.412) requires a supplier who understands its vital role.

Section 1: The Components of the Emergency Steering Pump

Inside Assembly 4646.137.412

The pump assembly includes:

- PISTON PUMP 0501.223.162: The core pump unit.

- O-RING 0634.316.304: The main seal (100X3) for the pump housing.

- HEXAGON SCREW 0636.010.416: For mounting the pump.

Section 2: Sourcing for Safety Compliance

The XiaoHang Quality Standard

Failure of the emergency pump is a safety hazard. XiaoHang Machinery Co.’s 20 years of technical experience ensures the replacement Piston Pumps we supply are manufactured to strict specifications, guaranteeing reliability when it matters most. Our strong inventory minimizes downtime for this critical safety component.

Conclusion: Do Not Compromise on Safety

Secure the precise PISTON PUMP 0501.223.162 and associated seal kits for your ZF 6WG310 Emergency Steering Pump assembly. Trust Tianjin XiaoHang Construction Machinery Co., Ltd.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| 5858518@gmail.com | |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

ZF 4WG310 Input Assembly: Sourcing High-Precision Input Shaft 4646.302.106 and Taper Roller Bearings

Introduction: The Core of the Driveline

The Input Assembly of the ZF 4WG310 (Assembly 4646.102.045) contains the most critical rotating components, including the input shaft and high-precision tapered roller bearings. Misalignment or bearing failure here causes complete transmission destruction.

This sourcing guide from Tianjin XiaoHang Construction Machinery Co., Ltd. helps you secure the correct, high-tolerance components for this high-stress assembly.

Section 1: Key Rotating Components

The Input Shaft and Its Supports

The input assembly, often paired with powerful engines, requires precision parts:

- INPUT SHAFT 4646.302.106: The main power input.

- HELICAL GEAR 4646.302.128: Transmits drive to the internal gearing.

- TAPERED ROLLER BEARING 0735.371.862: Two of these precision bearings are required to support the shaft.

Section 2: Sourcing High-Tolerance Bearings

The XiaoHang Precision Standard

Bearing tolerance is paramount. The TAPER ROLLER BEARING 0735.371.862 must meet precise dimensional and load specifications. XiaoHang Machinery Co.’s 20 years of repair expertise ensures our supplied bearings guarantee the long-term rotational integrity of the input shaft.

Section 3: Essential Sealing and Plug Components

Don’t Forget the Small Parts

This assembly also requires specific sealing parts: O-RING 0634.313.867 and various HEXAGON SCREWS (e.g., 0636.015.129) for sealing and mounting the OIL FEED FLANGE 4646.302.140. XiaoHang Machinery Co. provides all these minor parts alongside the major components.

Conclusion: Guarantee Driveline Integrity

For verified ZF 4WG310 input shafts and precision bearings, trust Tianjin XiaoHang Construction Machinery Co., Ltd.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| 5858518@gmail.com | |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

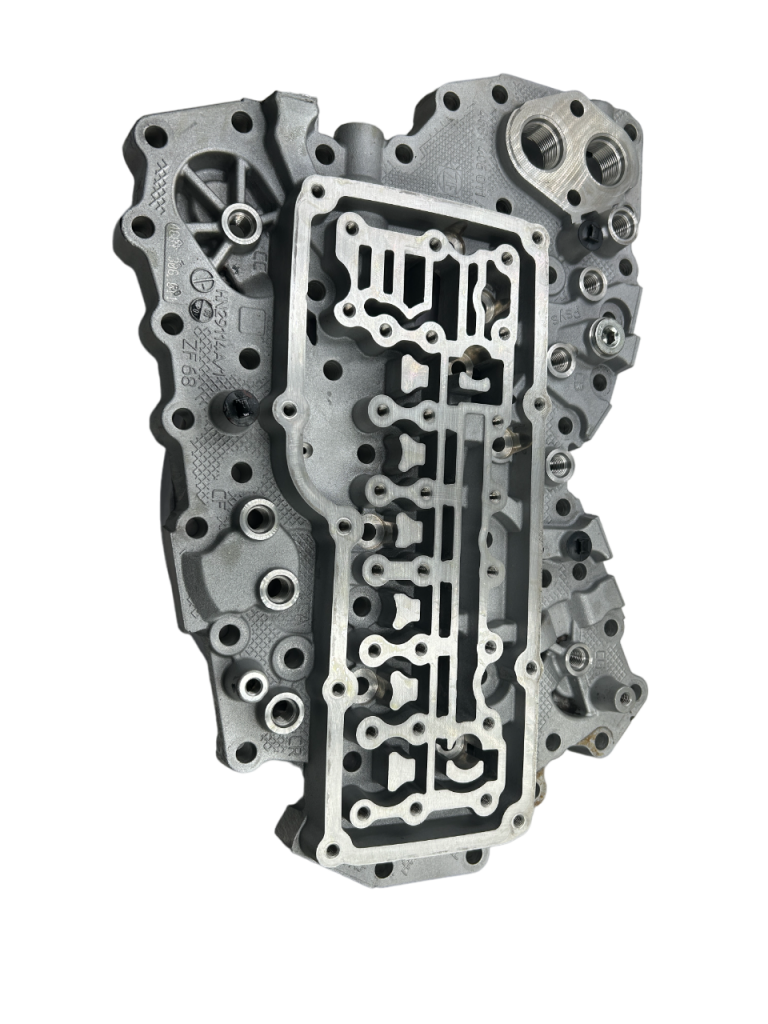

Introduction: The 16+2 bar Pressure Mystery

When a ZF 4WG200 (BOM 4644.024.146) experiences slippage or slow shifting, the cause is often a failure to maintain the specified 16+2 bar operating pressure. The challenge is determining if the problem is the primary Oil Pump or the Pressure Regulator.

This diagnostic guide from XiaoHang Machinery Co.’s 20-year experienced team helps technicians isolate the fault quickly.

Section 1: Testing the Pump vs. the Regulator

Targeting Assembly 4644.120.213

The Pressure Regulator assembly (4644.120.213) contains two critical valves: the CONV. SAFETY VALVE and the CONV. PRESS. VALVE.

- Pump Test: If the pressure reading at the main test port is low across all gears, the issue is likely the GEAR PUMP (or a massive internal leak).

- Regulator Test: If the pump is confirmed operational, the fault is likely wear on the PISTON 4644.320.034 or the COMPRESSION SPRING 0732.042.251 inside the pressure valve, causing oil to bypass and pressure to drop.

Section 2: Sourcing Verified Regulator Components

Precision Parts for Pressure Control

XiaoHang Machinery Co. supplies the specific internal components required for servicing the pressure regulator, including the PISTON 4644.320.034 and VALVE BUSH 4644.320.042. We ensure these parts meet precise tolerances to restore the 16+2 bar operating pressure.

Conclusion: Restore Optimal Pressure

Trust Tianjin XiaoHang Construction Machinery Co., Ltd.’s technical support to diagnose and supply the exact pressure regulator components needed for your 4WG200 repair.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| 5858518@gmail.com | |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

Introduction: Precision Sourcing for the 6WG191

The ZF 6WG191 transmission (BOM 4657.036.004) is designed for specialized vehicles like TERBERG Forklift Trucks. The essential power transfer component is the Torque Converter (TC). For this specific BOM, the required TC is 4168.034.131, which is a W340 converter without a lock-up clutch.

Procurement requires matching the precise specifications of this non-lock-up W340 unit.

Section 1: Technical Specifications You Must Verify

Matching the W340 Without WK (Lock-Up)

When sourcing the replacement CONVERTER 4168.034.131, ensure the supplier verifies these key specs from the technical cover:

- Model Designation: W 340

- Lock-Up Clutch: WITHOUT (ohne WK)

- Stall Torque Ratio: 2.10

Using a lock-up model TC in a non-lock-up application (or one with an incorrect stall ratio) will severely damage the transmission.

Section 2: The XiaoHang Procurement Guarantee

Zero Risk on High-Value Components

As a 20-year technical expert, XiaoHang Machinery Co. mitigates your risk by verifying the BOM and application. We supply high-quality replacement TCs that precisely match the non-lock-up design of the 4168.034.131. We maintain a strong inventory and offer fast lead times on these high-value components.

Conclusion: Source the Exact Converter You Need

Trust Tianjin XiaoHang Construction Machinery Co., Ltd. for verified ZF Torque Converters (Part No. 4168.034.131) and expert technical verification.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| 5858518@gmail.com | |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |