By TIANJIN XIAOHANG CONSTRUCTION MACHINERY .CO.LTD – Your Solution to Downtime

⏱️ Introduction: The Cost of Waiting

In the construction industry, time is literally money. For equipment using high-value systems like ZF transmissions (WG310, 5WG260, etc.), every day of downtime can cost thousands. For global parts distributors, the ability to promise and deliver immediate dispatch for critical spares is the single most powerful competitive advantage.

Tianjin Xiaohang Construction Machinery Co.Ltd has built its business model around a Deep Inventory Strategy and rapid logistics, transforming the usual multi-week waiting period into a matter of days.

I. The Deep Inventory Strategy: Ready to Ship Now

We understand that you cannot afford to wait for parts to be manufactured or shipped from factory warehouses halfway around the world.

- High-Volume Focus: Our inventory is strategically focused on the most critical, high-failure rate components across popular ZF models, including:

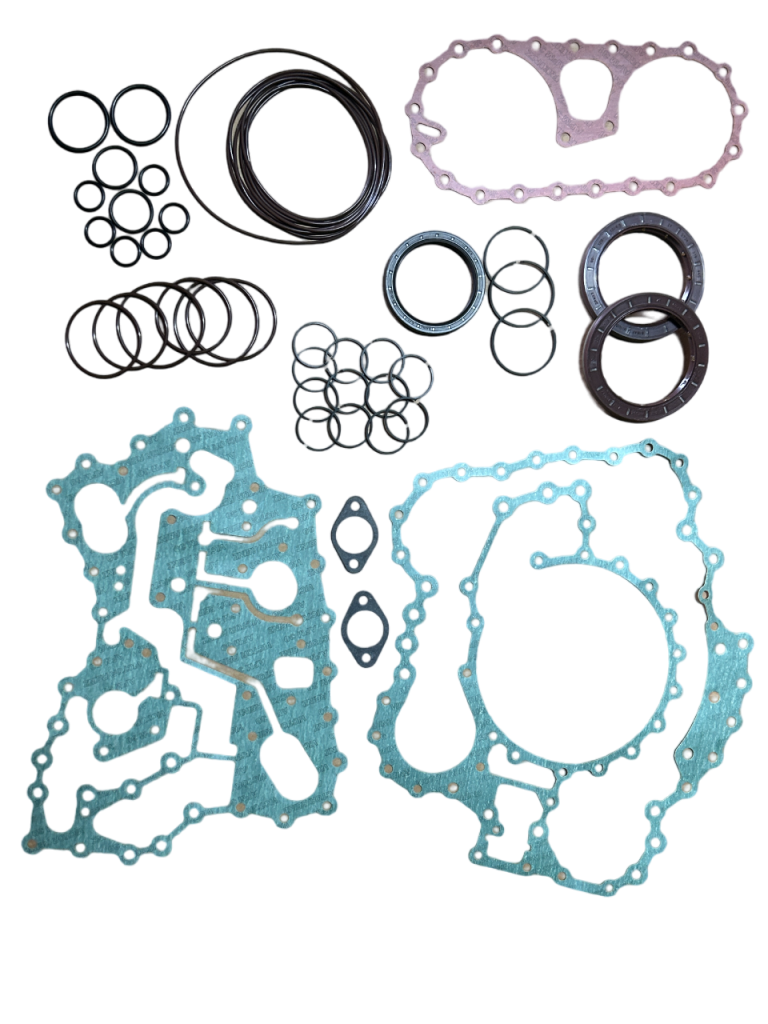

- Complete Overhaul Kits and Seal Kits for WG200, WG210, WG310.

- Solenoid Valve Packs and Control Units.

- High-wear Friction and Steel Plate Sets.

- Stock Guarantee: We maintain a sufficient storage of certified ZF components, allowing us to process and prepare your urgent order for dispatch immediately upon verification. If we quote it, we have it.

II. Seamless Logistics: From Stockroom to Your Customer

Our logistical efficiency is maximized by our unique position as an authorized dealer operating within the China manufacturing base.

- Fast Verification: Our in-house 20-year experienced engineers provide immediate verification of part numbers and specifications, eliminating the days often lost in back-and-forth technical queries.

- Streamlined Export: Our trading arm, Tianjin Linkworld Trading Co.Ltd, manages all export documentation, customs clearance, and global shipping arrangements, ensuring the fastest route possible to your global receiving point.

🚀 Our Dispatch Promise:

For in-stock, certified critical spares, our goal is immediate dispatch (within 24-48 hours of order confirmation) to minimize your customer’s downtime and secure your reputation as a reliable supplier.

III. Supporting Your Reputation with Reliability

Choosing a supplier with a reliable deep inventory directly supports your business growth:

- Competitive Edge: You can confidently quote shorter lead times than competitors who rely on slow, traditional supply chains.

- Risk Mitigation: Our certified inventory protects you from the sudden stock shortages and price spikes that plague the generic aftermarket.

Don’t let inventory hold you back. Leverage our deep stock and rapid dispatch capabilities to win more service contracts.

| Entity & Focus | Contact Information |

| Authorized Service Company | TIANJIN XIAOHANG CONSTRUCTION MACHINERY .CO.LTD |

| Email for Quotations | 5858518@GMAIL.COM |

| Direct Contact (Mobile/WhatsApp) | +86 15822863467 |

By TIANJIN XIAOHANG CONSTRUCTION MACHINERY .CO.LTD – Your Global Partner for Western OEM Spares

🚜 Introduction: ZF in North American Fleets

While CASE (C.N.H.) and John Deere are iconic American brands, many of their heavy-duty wheel loaders, graders, and dozers utilize robust, reliable ZF transmissions and axles to meet demanding performance specifications. For distributors servicing these key Western OEMs, reliable and fast sourcing of ZF components is crucial.

Tianjin Xiaohang Construction Machinery Co.Ltd bridges the gap between the official ZF supply chain and the needs of distributors in the Americas and globally, offering high-quality, certified spares for ZF-equipped CASE and John Deere fleets.

I. The CASE/John Deere ZF Component Landscape

Identifying the correct part often requires understanding the specific ZF model integrated into the OEM chassis.

- Common ZF Systems in CASE/JD: You will typically find ZF WG series transmissions (e.g., 4WG200, 5WG260) and BP series axles (e.g., BP210, BP230) in mid-to-heavy class loaders and graders from these OEMs.

- The Parts Number Challenge: CASE/John Deere parts manuals will list their own internal SKU (Stock Keeping Unit) number, which may differ from the final ZF Original Equipment (OE) number. This requires an accurate cross-reference.

Our Service Focus for CASE/JD Distributors:

- Cross-Reference Assurance: We convert the OEM’s part number (e.g., the CASE number for a solenoid) directly back to the verified ZF OE number, eliminating guesswork.

- Focus on Wear Items: We maintain high stock levels of commonly failed items specific to their applications, such as large transmission clutch kits and heavy-duty BP axle seals used in their specific models.

II. Our Competitive Advantage for International Sourcing

For distributors in North and South America, our model provides a distinct advantage over reliance on traditional Western supply chains:

- Speed & Inventory (WG200/BP230 Focus): While components for these models are manufactured globally, our deep, ready inventory in China allows us to bypass the common stock shortages and long lead times experienced by other suppliers.

- Pricing: Our streamlined supply chain and logistics (handled by Tianjin Linkworld Trading Co.Ltd) ensure our certified ZF parts are highly competitive, improving your profit margins without sacrificing quality.

- Expert Technical Backup: Facing a complex fault on a CASE 621D loader? Our 20-year experienced engineers provide the technical support needed to ensure the correct diagnosis and part replacement.

Servicing a CASE or John Deere fleet requires ZF precision. Partner with us for guaranteed quality and fast delivery.

| Entity & Focus | Contact Information |

| Authorized Service Company | TIANJIN XIAOHANG CONSTRUCTION MACHINERY .CO.LTD |

| Email for Quotations | 5858518@GMAIL.COM |

| Direct Contact (Mobile/WhatsApp) | +86 15822863467 |

By TIANJIN XIAOHANG CONSTRUCTION MACHINERY .CO.LTD – Your Official ZF Part Number Translator

🔢 Introduction: The Challenge of the 10-Digit Code

The ZF part number system is globally standardized, often utilizing a distinctive 10-digit code (e.g., $0750 \ 131 \ 001$). For parts distributors, the challenge is not just identifying the ZF original equipment (OE) number, but accurately finding a high-quality, cost-effective replacement component—a certified aftermarket alternative. Ordering based on a quick, unverified cross-reference is the leading cause of fitment errors.

Tianjin Xiaohang Construction Machinery Co.Ltd offers both the certified parts and the expert human cross-reference service to ensure your order is always 100% correct.

I. The Correct Cross-Reference Workflow

A reliable cross-reference should never be based on generic online tools alone.

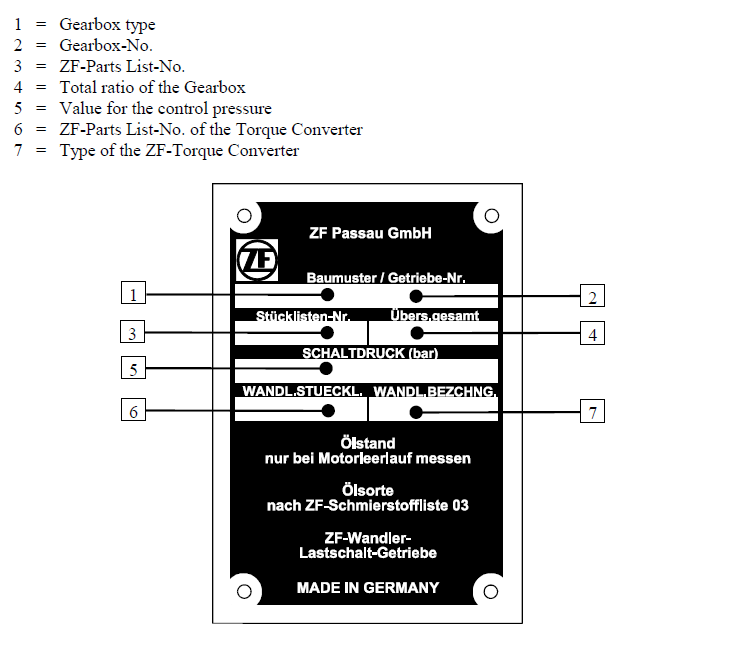

1. Start with the Foundation: The ZF Serial Number

Before attempting to cross-reference a specific component number, you must verify the ZF Serial Number (Sach-Nr) of the transmission it came from (as detailed in our previous guide, #16). This serial number is the master record that confirms the exact bill of materials (BOM) for that unit, including any superseded or revised component part numbers.

2. Verify the Component Number (OE or OEM)

Obtain the part number from the component itself (if visible) or from the OEM’s (e.g., CASE, XCMG) parts manual. This OEM number (which may be different from the ZF OE number) must then be traced back to the final ZF original part number.

3. Tianjin Xiaohang’s Authorized Cross-Reference

This is where generic sourcing fails and authorized sourcing wins.

- The Problem with Generic Cross-Referencing: Low-cost suppliers often use outdated or inaccurate online databases that do not account for supersession (when ZF revises a part and issues a new number) or OEM-specific versions.

- Our Solution: Our 20-year experienced engineers maintain access to current, authorized ZF technical data. We manually verify the superseded number and ensure that our high-quality replacement (an authorized aftermarket component) is the functionally and physically correct substitute for the OE part number you provided.

II. Why Our Certified Aftermarket Alternatives Are Superior

The term “aftermarket” is broad. We only supply Certified Aftermarket components that meet the exact material and dimension specifications of the ZF original part.

- Guaranteed Material Integrity: Unlike generic parts, our seals, friction discs, and gears are manufactured to withstand the thermal and pressure loads dictated by the original ZF engineering specifications.

- Reduced Liability: By providing you with a part cross-referenced and guaranteed by a ZF Authorized Dealer, you mitigate the risk of liability for using an incorrect or low-quality replacement.

Facing a complex superseded part number? Don’t guess. Send your list of part numbers and the transmission serial number to our experts for a guaranteed, accurate cross-reference.

| Entity & Focus | Contact Information |

| Authorized Service Company | TIANJIN XIAOHANG CONSTRUCTION MACHINERY .CO.LTD |

| Email for Quotations | 5858518@GMAIL.COM |

| Direct Contact (Mobile/WhatsApp) | +86 15822863467 |

By TIANJIN XIAOHANG CONSTRUCTION MACHINERY .CO.LTD – Your ZF Model Identification Specialist

🔍 Introduction: The Most Critical Piece of Data

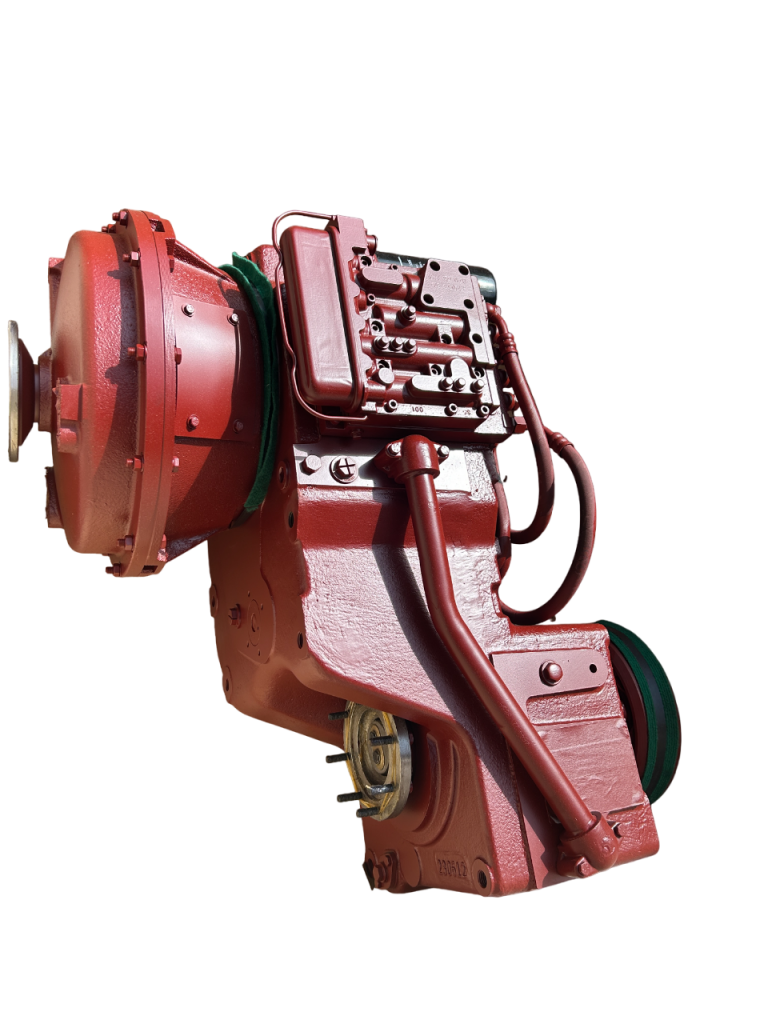

Before ordering a single spare part—whether a clutch kit, a solenoid, or a filter—you must know the precise model and serial number of the ZF transmission. Relying solely on the machine’s make and model (e.g., “Liugong 856 loader”) is dangerous, as OEMs often use variations (e.g., WG200 versus a modified 5WG210). The ZF identification plate is the single most important document for accurate part sourcing.

Tianjin Xiaohang Construction Machinery Co.Ltd provides this guide to help global distributors and technicians accurately locate and decode the data plate.

I. Locating the ZF Identification Plate

The plate is usually a small, stamped metal plate (or occasionally a sticker on newer units) affixed to the transmission housing.

- Common Locations:

- Side of the Housing: Near the gear shift lever input or control valve block.

- Top/Front Bell Housing: Often near the engine connection point.

- Bottom Sump Pan: Less common, but sometimes found on the oil pan mounting flange.

- Preparation: The plate is often covered in grime and oil. Clean the area thoroughly with a non-abrasive cleaner before attempting to photograph or record the numbers.

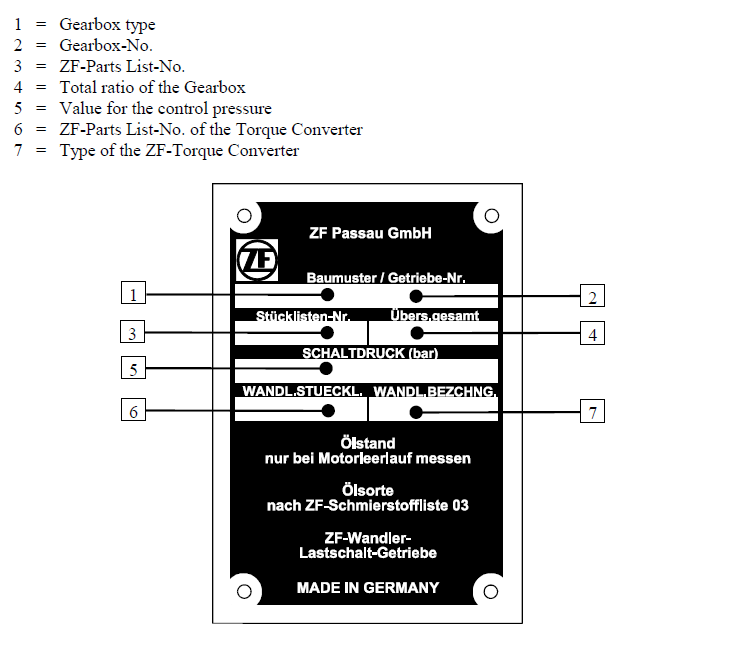

II. Deciphering the Key Data Fields

The plate contains two critical numbers that our parts specialists need for accurate sourcing:

| Data Field | Description | Why It’s Critical |

| 1. ZF Type (Model) | e.g., 4WG200, 5WG260, BP230. This identifies the basic series, gear count, and load capacity. | Determines the main overhaul kit and large component compatibility. |

| 2. Serial No. (Sach-Nr / Serial-Nr) | e.g., 4474 002 015. This is the unique identifying number for that specific transmission. | Crucial for ordering: It tells us the exact internal component configuration, revisions, and any OEM-specific parts used. |

💡 WG200 vs. WG210 Caution:

Never visually assume a model type. The ZF Type number distinguishes between very similar units like the 4WG200 (a standard 4-speed) and the 5WG210 (a 5-speed unit often requiring different clutches and valve calibration). The difference is only visible on the plate.

III. What to Do If the Plate is Missing or Unreadable

This is a common issue on older, heavily used equipment.

- Check Alternative Locations: Search the vehicle chassis for an accessory plate provided by the OEM (e.g., XCMG or CASE) that might list the ZF transmission details.

- Provide the OEM Part Number: Provide us with the OEM’s part number for the transmission or the failed sub-component (e.g., the Liugong part number for the valve body). We can often cross-reference this back to the original ZF number.

- Use Our Expert Identification Service: Send us clear photos of the transmission housing and surrounding components (oil cooler connections, shifter interface). Our 20-year experienced engineers can often identify the model series based on unique casting features.

Don’t risk ordering the wrong million-dollar part. Partner with us for guaranteed identification accuracy.

| Entity & Focus | Contact Information |

| Authorized Service Company | TIANJIN XIAOHANG CONSTRUCTION MACHINERY .CO.LTD |

| Email for Quotations | 5858518@GMAIL.COM |

| Direct Contact (Mobile/WhatsApp) | +86 15822863467 |

By TIANJIN XIAOHANG CONSTRUCTION MACHINERY .CO.LTD – Your Guardian Against Counterfeit Risk

🚨 Introduction: The High Price of a “Bargain”

The market for construction machinery spare parts is plagued by counterfeit ZF components. While these parts may be sold at tempting low prices, their failure rate is astronomically high, often leading to catastrophic, non-warrantable transmission failure and putting the machine operator at risk. For a global parts distributor, selling counterfeit components can destroy your reputation overnight.

As a ZF/ADVANCE Authorized Service Dealer, Tianjin Xiaohang Construction Machinery Co.Ltd is committed to providing a transparent, verified supply chain. We are your first line of defense against counterfeits.

I. The Risk: What Counterfeits Compromise

Counterfeiters focus on visual appearance, ignoring material quality and precision tolerance:

| Component Type | Counterfeit Risk | Impact of Failure |

| Friction Plates | Use of low-grade paper or composite material that burns easily. | Causes immediate slippage, overheating, and contamination. |

| Gaskets/Seals | Inferior rubber that degrades quickly under thermal stress. | Leads to critical pressure loss, causing failure in the hydraulic system. |

| Bearings | Substandard steel or incorrect heat treatment. | Leads to catastrophic failure, damaging shafts and gear housings. |

| Packaging/Labeling | Extremely convincing replicas of ZF boxes and labels. | The packaging is often the most deceitful part of the counterfeit product. |

II. Counterfeit Identification Checklist (Physical & Visual)

While packaging is tricky, specific physical details can expose a fake part:

- Look for Inconsistent Markings: Genuine ZF parts usually have clear, deeply stamped (not laser-etched) part numbers and manufacturer codes directly on the steel. Fakes often have shallow, fuzzy, or misaligned markings.

- Examine Surface Finish: Look for rough casting marks, burrs, or poorly machined edges on metal components (like pressure plates or pump casings). ZF components feature high-precision machining.

- Check the Sealing Material: Genuine seals feel pliable and dense. Fakes may feel stiff, brittle, or have an unnatural plastic smell.

- Verify the Security Hologram: While holograms are copied, look for distortions, poor image quality, or smudged printing on the label security features.

III. The Only Guaranteed Protection: Verified Sourcing

The most reliable way to protect your inventory and your customer’s machinery is to eliminate non-verified channels entirely.

- Source Directly from Authorized Dealers: Purchasing from an authorized service dealer like Tianjin Xiaohang guarantees the part’s origin, quality, and eligibility for any official ZF support. Our supply chain is 100% verified.

- Demand Certification: Insist on documentation that links the part to the official ZF supply chain. Generic resellers cannot provide this chain of custody.

- Technical Verification: Use our free technical support. Send us photos of a suspicious part or its packaging; our 20-year experienced engineers can often spot irregularities immediately based on their extensive exposure to both authorized and failed components.

Protect your reputation and your customers’ fleets. Do not take the risk of cheap, unverified components. Partner with us for guaranteed quality.

| Entity & Focus | Contact Information |

| Authorized Service Company | TIANJIN XIAOHANG CONSTRUCTION MACHINERY .CO.LTD |

| Email for Quotations | 5858518@GMAIL.COM |

| Direct Contact (Mobile/WhatsApp) | +86 15822863467 |

By TIANJIN XIAOHANG CONSTRUCTION MACHINERY .CO.LTD – Your WG310 and BP230 Inventory Specialist

🛠️ Introduction: Maximizing Uptime for ZF Workhorses

The ZF WG310 (a heavy-duty transmission) and the BP230 (a robust axle/brake system) are core components in large loaders, graders, and mining equipment globally. Maximizing the uptime of these machines requires a proactive inventory strategy focused on the most frequently failing wear parts.

As a ZF Authorized Service Dealer, Tianjin Xiaohang Construction Machinery Co.Ltd maintains a deep inventory of certified spares for these high-demand models. This guide helps you structure your stock to cover immediate repair needs.

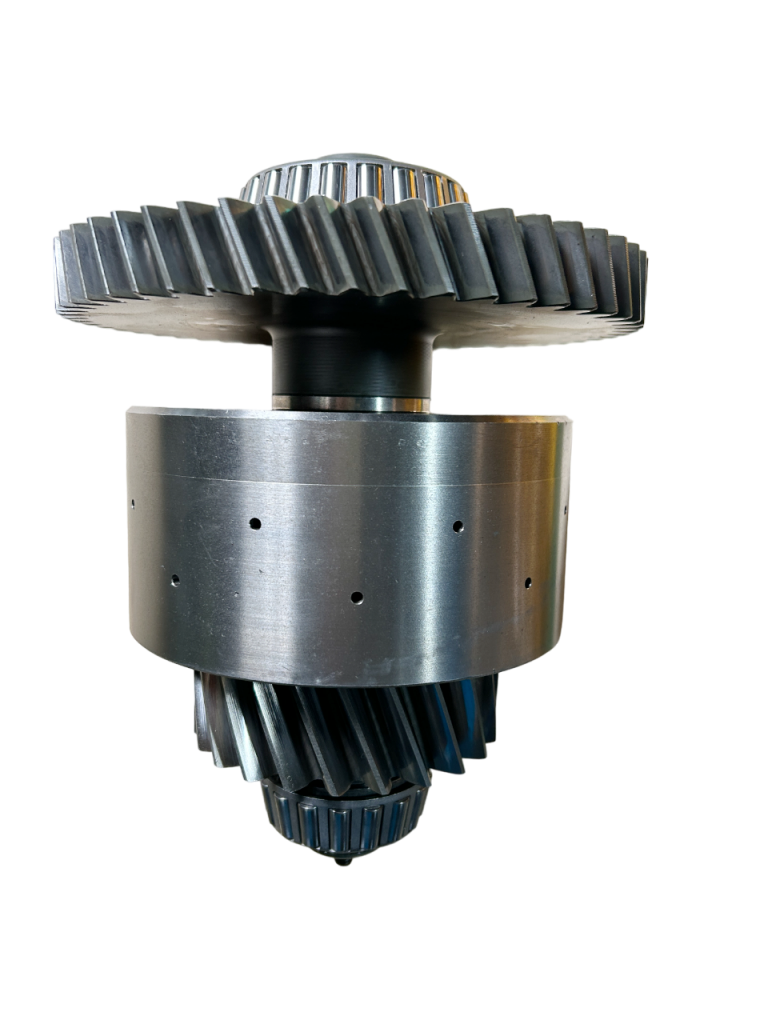

I. ZF WG310 Transmission: High-Friction and Hydraulic Kits

The WG310 is highly susceptible to wear within the clutch packs and the hydraulic sealing mechanisms due to its heavy-duty application.

| WG310 Wear Part Category | High-Demand Components to Stock | Why Stocking Genuine Parts Matters |

| Clutch Components | Friction Plate Sets (especially for high gears), Steel Reaction Plates, Clutch Piston Seals. | Non-genuine plates degrade quickly under the WG310’s high torque, contaminating the fluid rapidly. |

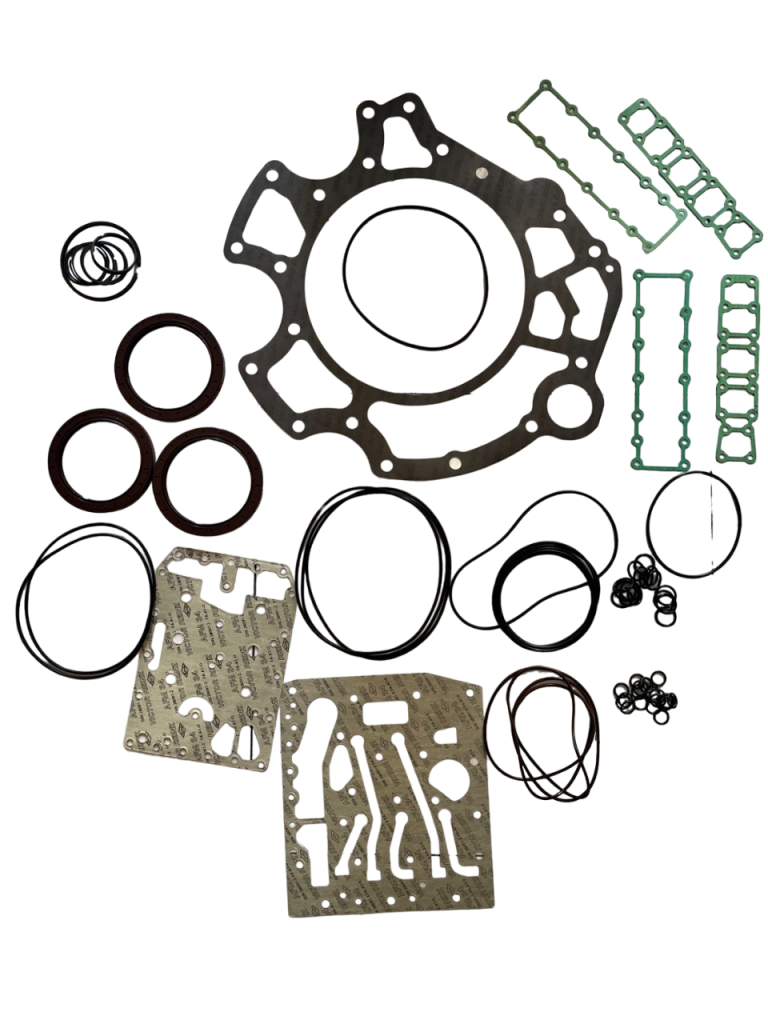

| Seal & Gasket Kits | Complete Overhaul Seal Kits, Input/Output Shaft Seals. | Seals are critical for maintaining hydraulic pressure integrity. Use of certified materials is non-negotiable. |

| Filtration | Hydraulic Filter Elements (main and pressure filters). | Stocking these prevents costly downstream damage from contamination. |

| Control Unit | Solenoid Valve Replacement Kits (common electrical failure point). | Solenoids are required for precise shift quality and temperature regulation. |

💡 Expert Tip:

For the WG310, always stock sufficient high-grade bearings as they are often replaced during major clutch pack overhauls to ensure proper shaft alignment and gear mesh.

II. ZF BP230 Axle/Brake System: Seals, Gears, and Stopping Power

The BP230 axle is critical for stability and braking efficiency. Its wear parts are focused on sealing, braking friction, and gear integrity.

| BP230 Wear Part Category | High-Demand Components to Stock | Why Stocking Genuine Parts Matters |

| Brake System | Brake Discs/Pads (Friction Material), Brake Piston Seals. | Braking components are safety-critical. Our certified parts guarantee thermal stability and friction coefficient consistency. |

| Sealing | Hub Seals, Differential Seals, Pinion Seals. | These seals fail due to heat and contaminants, leading to expensive gear oil loss and internal gear damage. |

| Differential/Final Drive | Selected Planetary Gear Pins, Thrust Washers, Spider Gears. | These components wear out under continuous differential load, requiring specific repair kits. |

III. Partnering with Tianjin Xiaohang for Inventory Management

Managing inventory for high-value items like WG310 and BP230 spares requires precision.

- Assured Supply: Our deep inventory strategy means we always have these critical WG310 and BP230 overhaul kits and individual components in stock, ready for immediate dispatch.

- Model Identification Support: Confused between a WG310 and a 5WG310 part? Our 20-year experienced engineers assist you in verifying the exact part number against the chassis or transmission serial number.

Need a rapid quote for a complete WG310 overhaul kit or BP230 brake pack? Contact us for our distributor pricing and immediate stock availability.

| Entity & Focus | Contact Information |

| Authorized Service Company | TIANJIN XIAOHANG CONSTRUCTION MACHINERY .CO.LTD |

| Email for Quotations | 5858518@GMAIL.COM |

| Direct Contact (Mobile/WhatsApp) | +86 15822863467 |

By TIANJIN XIAOHANG CONSTRUCTION MACHINERY .CO.LTD – Your Expert in Global OEM Compatibility

🌐 Introduction: The Complexity of Chinese OEM Sourcing

The global market is flooded with high-quality construction equipment from Chinese manufacturers like XCMG, Liugong, Sany, and SDLG. Many of these machines, particularly loaders and graders, rely on reliable ZF or ADVANCE transmissions (such as the 4WG200 and 6WG210) for their power systems.

A common question among global parts dealers is: Are the ZF components used in a Liugong 856H interchangeable with those in a Western brand machine, or even another Chinese brand like XCMG?

Tianjin Xiaohang Construction Machinery Co.Ltd is perfectly positioned to answer this. As a ZF Authorized Dealer based in China, we understand the nuances of OEM-specific part serialization and the true interchangeability limits.

I. The General Rule: ZF Core Components Are Interchangeable

For most standard ZF off-highway transmission models installed in Chinese machinery, the core internal components are fundamentally the same as those supplied globally.

1. What IS Interchangeable (If Model Matches):

- Friction and Steel Plates: These are standard internal wear items produced to ZF specification (e.g., for the 4WG200 or 5WG260 clutch pack).

- Gasket and Seal Kits: Standard seal kits are generally consistent across the same transmission model type.

- Solenoid Valves: The main electro-hydraulic control solenoids are usually standard ZF catalog items.

2. What IS NOT Always Interchangeable (OEM-Specific Parts):

- Casting and Housing: The transmission housing or bell housing often features specific mounting points, sensors, or casting elements dictated by the Chinese OEM’s (e.g., Liugong or XCMG) chassis design.

- Input/Output Flanges: The interface flanges that connect the transmission to the engine and the drive shaft may be specific to the OEM.

- Control Unit Calibration: The Transmission Control Unit (TCU) may contain specific software calibration unique to the OEM to optimize shifting for their particular engine and machine weight.

II. Identifying the Correct Part: The Mismatch Risk

The risk of ordering generic non-interchangeable parts is highest with Chinese brands because of rapid model evolution.

- The Serial Number is Key: Do not rely solely on the machine brand. You must obtain the ZF Serial Number and Model Type directly from the transmission’s identification plate.

- The Tianjin Xiaohang Solution: Our engineers specialize in cross-referencing Chinese OEM parts lists with the master ZF catalog. We help you verify the ZF type (e.g., confirming if a Liugong ZL50C uses a true ZF component or a locally manufactured ADVANCE component).

💡 Technical Focus: ADVANCE Transmission Parts

Many Chinese loaders utilize ADVANCE Group transmissions. As an ADVANCE Group Authorized Service Dealer as well, Tianjin Xiaohang is equipped to supply certified parts for both ZF and ADVANCE systems, covering nearly all Chinese OEM requirements.

III. Sourcing Advantage: Mastering the China Supply Chain

For global dealers, sourcing from an authorized Chinese partner is the most efficient strategy for servicing XCMG and Liugong fleets.

- Speed and Price: We leverage our local presence to ensure immediate stock availability and highly competitive pricing on both ZF and ADVANCE certified spares, minimizing the reliance on costly, slow international freight.

- Quality Assurance: By sourcing certified parts through us, you avoid the common risk of counterfeit goods prevalent in some non-official Chinese trade channels.

Facing a parts identification issue for a specific XCMG or Sany machine? Don’t risk ordering the wrong part. Contact our specialists for immediate cross-referencing and assured supply.

| Entity & Focus | Contact Information |

| Authorized Service Company | TIANJIN XIAOHANG CONSTRUCTION MACHINERY .CO.LTD |

| Email for Quotations | 5858518@GMAIL.COM |

| Direct Contact (Mobile/WhatsApp) | +86 15822863467 |

By TIANJIN XIAOHANG CONSTRUCTION MACHINERY .CO.LTD – Your Experts in ZF Failure Analysis

🔥 Introduction: When Temperature Alarms Won’t Stop

Persistent overheating in a ZF off-highway transmission (like the 4WG200 or 6WG210) is a critical symptom that often goes beyond simple maintenance errors. If fluid levels and filters have been checked, the problem lies deeper, usually within the hydraulic circuits or the cooling system itself. Ignoring sustained high temperatures will inevitably lead to damage of clutch packs and expensive housing deformation.

Tianjin Xiaohang Construction Machinery Co.Ltd specializes in providing the precise, certified components and technical guidance needed for deep-level fault resolution.

I. The Cooling Circuit: Is Your Heat Exchanger Working?

The primary cause of persistent overheating is the failure to reject heat effectively.

1. Oil Cooler Internal Blockage

- Diagnosis: If the cooler’s internal passages are clogged with sediment, carbon, or debris (often indicated by a very small temperature drop across the cooler), heat exchange becomes ineffective.

- The Part Solution: A complete cooler replacement is often the safest bet. We supply genuine-standard ZF oil cooler units.

- Our Technical Check: Before shipping, our engineers confirm the heat exchange capacity matches your specific ZF model and application (e.g., high-altitude mining vs. standard construction).

2. Auxiliary Cooling System Failure

- Diagnosis: If the transmission shares a cooling loop with the engine, ensure the engine’s coolant is clean and the thermostat is functioning correctly. Low water flow or a failed engine fan clutch can indirectly starve the transmission cooler of cooling medium.

- The Part Solution: While not a ZF part, securing high-quality engine cooling components from a trusted source is part of the full solution.

II. Hydraulic System Breakdown: The Pressure is Off

High temperature is often the byproduct of excessive internal friction caused by low hydraulic pressure.

1. Control Valve Body Malfunction (Solenoid Issues)

- Diagnosis: A sticking solenoid valve or worn pressure regulation valve within the control valve body can fail to maintain the required pressure to engage a clutch pack firmly. This leads to slippage, which is instantly converted into intense heat.

- The Part Solution:We provide genuine ZF solenoid valve kits and complete valve bodies. Replacing the entire unit often guarantees correct pressure calibration.

- Targeted Spares: Focus on solenoid valve replacement part numbers for your specific WG model (e.g., ZF 5WG200 solenoid valve pack).

2. Piston Seals and Ring Failures

- Diagnosis: The seals (piston rings and sealing rings) that direct oil pressure to engage the clutch packs are a common wear item. When they fail, oil pressure leaks, causing the clutch to partially engage and slip severely.

- The Part Solution: Immediate replacement of the entire seal and gasket kit is necessary. We ensure our kits use materials (Viton/NBR) that withstand the high thermal stress experienced by ZF systems.

III. The Final Verdict: Torque Converter Slippage

- Diagnosis: If all other checks are clear, the torque converter lock-up clutch may be slipping, creating massive heat without registering major pressure faults elsewhere. This is usually confirmed by excessive RPM difference between the input and output shafts under load.

- The Part Solution: We strongly advise replacing the T/C with a high-quality, certified unit. We stock ZF torque converter units for immediate dispatch.

🤝 Tianjin Xiaohang’s Guaranteed Supply and Support

When you’re diagnosing complex heat-related failures, you need certainty in your supply. Our status as a ZF/ADVANCE Authorized Dealer combined with our deep Chinese inventory guarantees you:

- Rapid Delivery of Heat-Resistant Spares: We prioritize immediate dispatch of time-critical components like coolers, valve bodies, and seals.

- Expert Consulting: Contact our 20-year experienced engineers directly for remote guidance on complex pressure readings or temperature logs.

| Entity & Focus | Contact Information |

| Authorized Service Company | TIANJIN XIAOHANG CONSTRUCTION MACHINERY .CO.LTD |

| Email for Quotations | 5858518@GMAIL.COM |

| Direct Contact (Mobile/WhatsApp) | +86 15822863467 |

By TIANJIN XIAOHANG CONSTRUCTION MACHINERY .CO.LTD – Balancing OEM Quality and Competitive Pricing

📉 Introduction: The Distributor’s Dilemma—Price vs. Performance

For construction machinery parts distributors worldwide, procurement often presents a critical challenge: balancing the immediate cost of parts with the long-term operational success of your customers. Many generic aftermarket suppliers tout extremely low prices, but this strategy often ignores a fundamental truth about complex drivetrain components like ZF transmissions: a minor upfront saving can quickly lead to catastrophic, costly downtime.

As an Authorized ZF/ADVANCE Service Dealer, Tianjin Xiaohang Construction Machinery Co.Ltd, we understand this trade-off. Our unique position—combining official ZF certification with the efficiency of China’s strong manufacturing base—allows us to offer genuine quality spares at a highly competitive price point, ensuring a superior Long-Term Return on Investment (ROI) for your business and your clients.

This article dissects the true cost of generic parts versus the value-driven proposition offered by Tianjin Xiaohang’s authorized spare components.

I. The True Cost of Non-Genuine Components

A generic clutch plate or seal kit might look identical to the genuine ZF part, but the performance difference in a high-stress transmission system is immense. The cost of a non-genuine part goes far beyond its purchase price.

1. The Hidden Cost of Inferior Materials

- Friction and Heat: Generic friction plates often use lower-grade materials that cannot withstand the high temperatures (as discussed in our previous article) and pressure cycles of ZF transmissions (e.g., WG200, 4WG200). They wear out faster and, critically, accelerate wear on surrounding steel plates and components.

- Sealing Failure: Non-genuine seals (O-rings, gaskets) are often made from cheaper elastomers (rubber materials) that quickly degrade, harden, or shrink when exposed to hot transmission fluid. This leads to pressure leaks and slippage, resulting in catastrophic system failure.

🛑 Expert Insight: Downtime Multiplier

If a generic part saves you 10% on the purchase price but causes the machine to fail three months early, the cost of emergency repair, lost productivity (downtime), and labor for the second repair will multiply your original savings by a factor of five to ten times. Your customers trust you for reliability; non-genuine parts compromise that trust.

2. The Cost of Inaccurate Fitment and Lack of Precision

ZF components, especially in hydraulic control units (valve bodies) and gear sets, require micrometer-level precision.

- Tolerance Issues: Generic components frequently suffer from poor tolerance control. A small deviation in the thickness of a steel plate or the inner diameter of a bearing can disrupt the hydraulic pressure and gear mesh, leading to noise, vibration, and premature failure across the entire assembly.

- Zero Technical Support: When a generic part fails, the distributor (you) is left without any recourse or technical guidance. There is no official procedure or engineer support to help you diagnose the secondary damage.

II. The Tianjin Xiaohang ROI Advantage: Authorized Quality Meets Market Price

Our business model is engineered to deliver the long-term ROI you need, without forcing you to pay the premium associated with traditional international distributors.

1. Guaranteed Quality: The ZF Authorized Seal

Every part supplied by Tianjin Xiaohang Construction Machinery Co.Ltd is backed by our official authorization from the ZF/ADVANCE Group. This means:

- Standardized Quality: Our components are manufactured, tested, and stored according to ZF’s rigid specifications, ensuring perfect fitment and material integrity.

- Technical Integrity: As an authorized service dealer, we adhere to the most recent standardized maintenance and testing procedures. This guarantee extends to the parts we sell, ensuring they perform exactly as the original manufacturer intended.

2. Unbeatable Supply Chain Reliability

We eliminate the biggest procurement headaches for global distributors: stock availability and logistics speed.

- Deep Inventory Stock: We maintain vast, sufficient storage of certified ZF products. This large, proactive inventory eliminates the long lead times associated with factory orders. We guarantee immediate dispatch for critical spares (e.g., high-demand kits for WG200, WG310, BP230).

- Logistics Efficiency: Through our dedicated foreign trade entity, Tianjin Linkworld Trading Co.Ltd, we streamline all international shipping and customs processes. This leverages China’s sophisticated manufacturing base to ensure rapid supply cycles at highly competitive freight and component costs globally.

3. Value-Added Service: Expert Technical Support

Your purchase from us includes a critical, often free, component that generic suppliers cannot offer: Expert Consultation.

⭐ The 20-Year Experience Guarantee

Every accessory you purchase from us comes with the full support of our 20-year experienced engineering team. If your customer faces difficulty identifying the fault or the correct part number, our experts will step in to help you identify faults and provide precise maintenance or parts replacement comments accordingly. This technical certainty drastically reduces the risk of incorrect ordering and repeat repairs.

📈 Summary: Calculating the Superior ROI

The ROI of choosing Tianjin Xiaohang is calculated not just by the competitive price we offer, but by the following factors:

- Minimized Warranty Claims: Authorized quality dramatically reduces the chance of parts failure, protecting your reputation.

- Reduced Downtime: Quick dispatch and accurate ordering (thanks to technical support) ensure your customers’ machinery is back up faster.

- True Component Longevity: Genuine-standard parts perform longer, reducing the total lifecycle cost of the equipment.

We serve clients whose fleets rely on ZF transmissions in machinery manufactured by Hyundai, CASE, Komatsu, XCMG, Liugong, and Sany. Choose the authorized partner who understands both quality and cost.

📞 Contact Us for Parts and Expert Consultation

Ready to source genuine ZF parts quickly, or need expert guidance on a specific fault? Contact our authorized team directly.

| Entity & Focus | Information |

| Authorized Service Company | TIANJIN XIAOHANG CONSTRUCTION MACHINERY .CO.LTD (Technical Service) |

| International Trading Arm | TIANJIN LINKWORLD TRADING CO.LTD (Global Sourcing & Logistics) |

| Email for Quotations | 5858518@GMAIL.COM (Best for detailed inquiries & RFQs) |

| Direct Contact (Mobile/WhatsApp) | +86 15822863467 (For urgent requests and technical questions) |

We look forward to partnering with you to secure the long-term reliability of global construction machinery.

By TIANJIN XIAOHANG CONSTRUCTION MACHINERY .CO.LTD – Your Authorized ZF/ADVANCE Service Dealer

⚙️ Introduction: High Oil Temperature is the Silent Killer of ZF Drivetrains

In the daily operation of heavy-duty construction machinery—from loaders and graders to compactors—the ZF transmission system is the core of power delivery. However, when the transmission oil temperature consistently exceeds the normal range (typically above $120^\circ\text{C}$ or $250^\circ\text{F}$), it’s far more than a simple dashboard warning. It signifies accelerated internal wear that leads to permanent damage, seal hardening, friction plate burnout, and ultimately, costly, unexpected equipment downtime.

As an Authorized Service Dealer for the ZF/ADVANCE Group—Tianjin Xiaohang Construction Machinery Co.Ltd, we benefit from official technical support and a team of professional engineers with two decades of industry experience. Our mission is to help global parts distributors and repair technicians accurately and quickly diagnose these issues, providing solutions that are OEM-standard and quickly supplied.

This article provides an authoritative, step-by-step checklist for troubleshooting high ZF transmission oil temperature, focusing on the most critical components and the necessary genuine aftermarket parts solutions.

I. Diagnosis Core: Fluids and Filtration (The Foundation)

Before undertaking any complex mechanical inspections, you must address the basics. Over 80% of initial overheating cases stem from poor fluid health or maintenance errors.

1. Oil Level and Fluid Quality Check

- Problem Diagnosis: Low fluid levels lead to inadequate lubrication and circulation, generating excessive heat. Conversely, overfilling causes oil churning and foaming, reducing the fluid’s cooling capacity. The wrong fluid type or heavily contaminated oil significantly compromises thermal stability.

- Actionable Advice: Adhere strictly to ZF official fluid specifications and replacement cycles. If the oil is burnt, discolored, or smells scorched, assume internal friction component damage has occurred.

- How We Help: We guide you in selecting the precise ZF-recommended fluid and ensure your filtration system is running optimally.

2. Hydraulic Filter Blockage

- Problem Diagnosis: A clogged filter element restricts oil flow, immediately reducing lubrication and cooling efficiency while forcing the oil pump to work under excessive stress, which itself generates heat.

- Solution & Safety: Timely replacement is critical. Insist on using genuinely certified filter components. Non-genuine elements often have inadequate filtration ratings or incorrect dimensions, leading to a breakdown in fluid cleanliness and component damage.

💡 Quick Tip:

For maintenance, always check the magnetic plug (if equipped) for excessive metal shavings. Large, sharp fragments indicate catastrophic failure; fine sludge points toward normal wear or minor contamination.

II. Critical Component Failure Investigation (The Hard Parts)

If fluid and filtration are ruled out, the temperature issue is likely rooted in one of the following three high-stress components.

1. The Transmission Oil Cooler (Heat Exchanger)

The cooler is the transmission’s primary heat rejection mechanism.

- Problem Diagnosis: Internal clogging (from scale, sludge, or internal debris) or external damage to the fins severely diminishes the cooler’s ability to dissipate heat. This is a common failure point in harsh operating environments.

- Key Test: Check the temperature difference between the oil entering and exiting the cooler. A minimal temperature drop ($<5^\circ\text{C}$) suggests internal blockage, necessitating cleaning or replacement.

- Tianjin Xiaohang Solution: We supply OEM-standard ZF oil cooler replacement units. As an authorized dealer, we guarantee that our genuine aftermarket components match the precise heat dissipation capacity required by ZF/ADVANCE specifications.

- Parts Sourcing Keywords: ZF oil cooler replacement cost, ZF 4WG200 heat exchanger.

2. Torque Converter (T/C) Malfunction

The T/C is a significant source of hydraulic heat generation.

- Problem Diagnosis: If the lock-up clutch is slipping or has failed, it creates immense frictional heat, often leading to rapid oil temperature spikes. Failure to lock up means continuous hydraulic slippage, resulting in overheating and severe power loss.

- Solution & Implantation: T/C internal faults are complex. For reliable, long-term repair, replacement with an officially certified remanufactured or new unit is generally recommended over a simple component repair.

3. Excessive Wear of Clutch Packs and Seals

This is the most direct cause of overheating due to friction.

- Problem Diagnosis: Worn friction plates or failed seals (O-rings, piston seals) lead to hydraulic pressure leakage. This prevents the clutches from fully engaging, causing severe, heat-generating slippage under load.

- Actionable Advice: Diagnose the hydraulic pressure within the clutch circuits. If pressure is low, focus on replacing seals and the control valve. If pressure is good but slippage occurs, immediate replacement of the friction and steel plates is necessary.

⭐ The Genuine Parts Difference

A Critical Note on Quality: When performing repairs, every manufacturer stresses the importance of using certified, genuine aftermarket components. Non-genuine parts often utilize inferior materials that fail under the high-pressure, high-temperature conditions of a ZF transmission. Trust in your equipment—now put your trust in Genuine ZF Aftermarket Parts & Components.

III. The Tianjin Xiaohang Value Proposition: Speed, Expertise, and Trusted Sourcing

For global construction machinery parts distributors, procurement must balance quality (ZF standard) with logistical speed and cost-effectiveness. Our dual-entity structure ensures this balance.

| Our Advantage | Direct Benefit to You (The Distributor) |

| ZF Authorized Status | Risk-Free Sourcing. All parts adhere to official ZF/ADVANCE standards, minimizing warranty risk. |

| Deep Inventory Stock | Immediate Dispatch. We guarantee sufficient current stock for critical spares (WG200, WG310, BP230), reducing customer downtime. |

| China Manufacturing Base | Competitive Pricing & Speed. Leveraging our foundation and our trading arm, Tianjin Linkworld Trading Co.Ltd, we ensure rapid supply cycles globally. |

| 20-Year Expert Team | Free Technical Support. Purchase includes consultation with our engineers to help you accurately diagnose the fault and confirm the correct part. |

When you serve customers using ZF transmissions in machinery from international brands like Hyundai, CASE, Komatsu, or Chinese leaders like XCMG, Liugong, and Sany, your reputation depends on the quality and speed of your parts supply.

📞 Conclusion & Contact Us

High transmission oil temperature is a complex indicator requiring systematic, professional diagnosis. Choosing a reliable, authorized supplier is the final and most critical step in the repair process.

Tianjin Xiaohang Construction Machinery Co.Ltd is your official partner. We provide the expertise for diagnosis and the original-standard components for a lasting repair solution.

If you are sourcing critical spares for specific ZF models (WG200, WG310, BP230, etc.) or require expert technical guidance on a high-temperature fault, contact our authorized team directly.

Your Direct Contact Details:

| Entity | Details |

| Authorized Service Company | TIANJIN XIAOHANG CONSTRUCTION MACHINERY .CO.LTD |

| International Trading Arm | TIANJIN LINKWORLD TRADING CO.LTD |

| Email for Quotations | 5858518@GMAIL.COM (Best for detailed inquiries) |

| Direct Contact (Mobile/WhatsApp) | +86 15822863467 |

We look forward to partnering with you to secure the long-term reliability of global construction machinery.