Maintaining Heavy-Duty: Sourcing Components for Large ZF Axle Systems in Mining and Port Equipment

Introduction: Extreme Load, Extreme Demands

Large ZF axle systems used in mining trucks, port cranes, and heavy-duty vehicles face immense torque and continuous load. Maintaining these specialized axles requires suppliers who understand the high-stress environment and can provide parts built for extreme durability.

This technical sourcing guide from XiaoHang Machinery Co. is aimed at managers procuring high-wear, large-scale axle components.

Section 1: Key Stress Points in Large ZF Axles

High-Value Replacement Items

Critical items include: 1. Planetary Gear Sets: Must handle extreme torque cycles. 2. Differential Lock Systems: Prone to wear under heavy load. 3. High-Capacity Bearings: Required to withstand sustained, heavy-duty operation.

Section 2: Procurement and Durability Assurance

Material Specification is Key

Axle components must feature correct metallurgy and hardening processes. XiaoHang Machinery Co. ensures the integrity of these components, leveraging our technical expertise to verify manufacturing standards. We offer fast lead times on these large, specialized parts.

Conclusion: Specialized Parts for Specialized Machinery

Trust Tianjin XiaoHang Construction Machinery Co., Ltd. to supply the durable ZF axle components required for high-stress mining and port operations.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

Why Leading Global Distributors Choose Aftermarket Specialists Over OEM Dealers for ZF Parts

Introduction: The Economics of Specialized Supply

Global distributors seek reliability and profitability. While OEM dealers offer genuine parts, specialized aftermarket suppliers offer a compelling economic and technical advantage.

This guide from Tianjin XiaoHang Construction Machinery Co., Ltd. details the strategic reasons why procurement managers increasingly rely on expert aftermarket partners.

Section 1: The Three Pillars of Aftermarket Advantage

- Cost Efficiency: Specialist suppliers like XiaoHang Machinery Co. leverage global supply chains (like the Chinese manufacturing base) to offer competitive pricing without the OEM’s overhead.

- Technical Focus: We focus solely on transmission and driveline components, ensuring deep, vertical expertise and accurate cross-referencing—a guarantee not always available from broad-scope OEM channels.

- Lead Time Certainty: Our strong inventory and streamlined logistics guarantee fast lead times, reducing the risk of machine downtime.

Section 2: The Technical Guarantee

- XiaoHang’s 20-Year Assurance: We back every part with our technical support team, providing the ultimate guarantee against installation errors and premature failure.

Conclusion: The Smart Procurement Decision

Make the profitable and technically sound choice. Partner with XiaoHang Machinery Co. for your ZF parts supply.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

ZF WG Series Transmission Oil Pump Failure: Diagnosis, Replacement, and Procuring Verified Units

Introduction: The Hydraulic Heartbeat

The oil pump is the hydraulic heart of the ZF WG series transmission. Its failure instantly compromises control pressure, leading to slippage and catastrophic component damage. Rapid and accurate sourcing of a quality replacement pump is paramount.

This technical guide from XiaoHang Machinery Co. focuses on diagnosing oil pump failure and securing a reliable replacement unit.

Section 1: Recognizing Oil Pump Failure

Symptoms and Checks

A failing pump typically results in low or inconsistent pressure readings across all clutch test ports. This may manifest as delayed gear engagement or lack of lock-up. Contamination (metal particles) is a primary cause of pump wear.

Section 2: Procurement Considerations for Oil Pumps

Quality Assurance on Internal Housings

Replacement pumps must guarantee precise flow and pressure delivery. XiaoHang Machinery Co. supplies oil pumps that undergo strict quality checks on internal housings and gear tolerances. Our fast lead times minimize downtime for this crucial repair.

Conclusion: Restore Hydraulic Pressure with XHC

Trust our 20 years of technical expertise to secure a high-quality replacement oil pump for your ZF WG series transmission.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

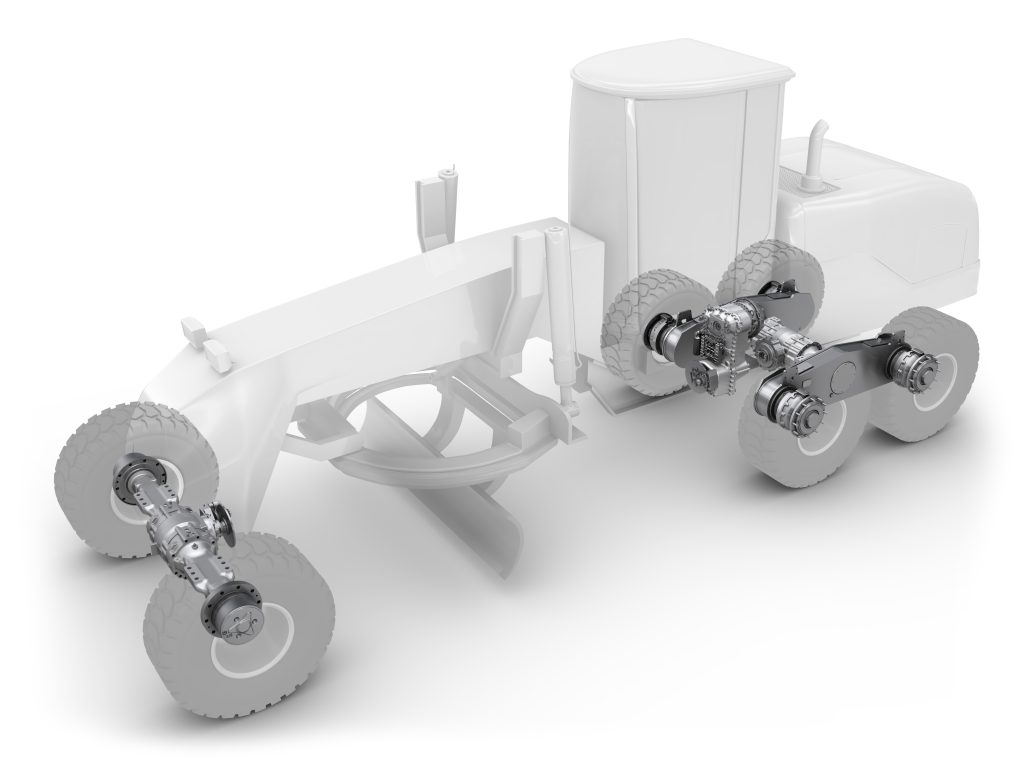

Expanding Your Inventory: Sourcing ZF Axle and Driveline Components for Comprehensive Service

Introduction: A Complete Driveline Solution

While transmissions are key, many ZF-equipped machines also utilize ZF axles and driveline components. For distributors, offering a complete driveline solution (transmissions and axles) maximizes customer retention and sales opportunities.

This guide from XiaoHang Machinery Co., a full-service supplier for off-highway vehicles, helps you strategically expand your inventory to include high-demand ZF axle and driveline spares.

Section 1: High-Demand ZF Axle Components

Key Parts Beyond the Transmission

High-wear axle items typically include: 1. Differential Gears and Housings. 2. Final Drive Components (Planetary Gears). 3. Axle Shafts and Bearings.

Section 2: Sourcing Strategy for Axle Components

Precision and Load Rating

Axle parts must meet the exact load rating and gear specifications. XiaoHang Machinery Co.’s 20 years of expertise ensures the axle components we supply meet the rigorous demands of heavy construction and mining applications. We offer fast lead times on these bulky, high-value components.

Conclusion: Complete Your Driveline Service

Expand your service offerings. Contact XiaoHang Machinery Co. today to source verified ZF axle and driveline components at competitive prices.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

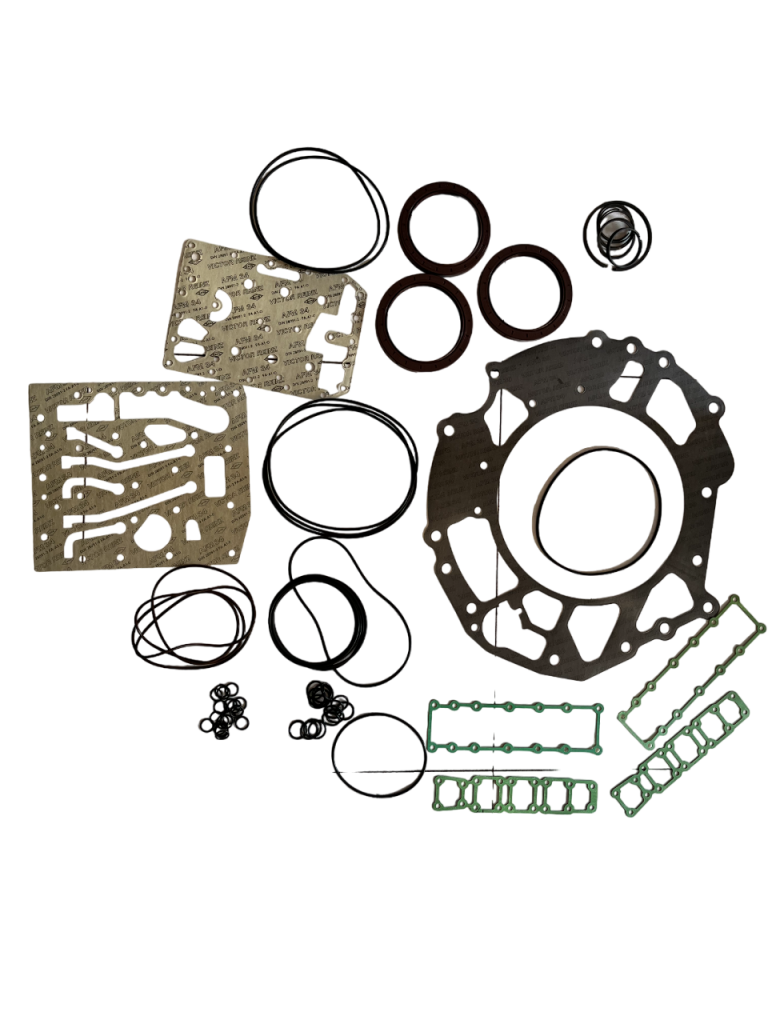

Beyond Gaskets: The Critical Role of Piston Sealing Rings in ZF Transmission Hydraulic Pressure Maintenance

Introduction: The Unseen Heroes

While external leaks are obvious, internal pressure leaks caused by failing sealing rings (often PTFE or composite rings) are the silent killers of ZF performance, leading directly to clutch slippage and overheating. This component failure requires a supplier who understands high-precision internal seals.

This technical deep-dive from XiaoHang Machinery Co. focuses on the procurement and technical importance of high-quality sealing rings.

Section 1: How Failing Sealing Rings Cause Slippage

The Chain Reaction

Sealing rings in the clutch drum channels maintain hydraulic pressure required to actuate the clutch pack. When these rings wear, pressure bypasses the clutch, reducing the clamping force. This slippage generates heat and contaminates the oil.

Section 2: Sourcing High-Precision Sealing Rings

Quality Assurance is Paramount

Internal seals must be sourced from suppliers guaranteeing correct material composition and dimensional tolerance. Substandard rings fail immediately under pressure and heat. XiaoHang Machinery Co. supplies high-grade sealing rings verified by our 20 years of repair expertise.

Conclusion: Protect Internal Pressure with XHC Seals

Don’t let small seals cause massive failure. Secure high-precision sealing kits from Tianjin XiaoHang Construction Machinery Co., Ltd., backed by our technical guarantee.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

ZF WG171 and WG201 Transmissions: Key Maintenance Parts and Expert Sourcing Guide

Introduction: Focused Maintenance for WG171/WG201

The ZF WG171 and WG201 series are common in various construction and specialized machinery. Maintaining these units requires specific technical knowledge to ensure accurate parts procurement, particularly for high-wear items.

This focused guide from XiaoHang Machinery Co. outlines the critical parts and procurement strategy for these specific ZF models.

Section 1: High-Wear Components in WG171/WG201

Your Essential Inventory Checklist

For these models, high-frequency replacements often include: 1. Clutch Plates and Steel Discs: Due to operational cycles. 2. Main and Suction Filters: Essential for hydraulic system protection. 3. Electronic Sensors: Prone to thermal cycling failure.

Section 2: The XiaoHang Advantage for Specific Models

Speed and Precision for WG171/WG201

XiaoHang Machinery Co. maintains a strong, dedicated inventory for specific high-demand models like the WG171 and WG201. This specialization ensures that distributors receive fast lead times and highly competitive pricing on both small maintenance kits and major overhaul components. Our 20 years of technical support is available for complex disassembly and assembly questions related to these models.

Conclusion: Specialized Support for WG171/WG201

Trust Tianjin XiaoHang Construction Machinery Co., Ltd. for precise, verified parts for your WG171 and WG201 maintenance needs.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

Hyundai Wheel Loaders: Sourcing ZF Transmission and Axle Parts for Maintenance and Repair

Introduction: The Hyundai-ZF Performance Standard

Hyundai Construction Equipment, known for its robust wheel loaders and excavators, often integrates ZF components to ensure heavy-duty performance and reliability. Accurate maintenance of these machines requires a supplier who understands the ZF components specific to Hyundai applications.

This guide from Tianjin XiaoHang Construction Machinery Co., Ltd. assists distributors in accurately identifying and procuring the correct ZF transmission and axle spares for Hyundai construction vehicles.

Section 1: Common ZF Components in Hyundai Loaders

What to Look for on the Nameplate

Certain Hyundai wheel loaders utilize specific ZF transmissions (and often ZF axles) to handle heavy loads. Technicians should look for model numbers like variants of the ZF 4WG200 or 6WG310 on the transmission nameplate.

Section 2: Ensuring Compatibility with Hyundai Specifications

BOM Verification for OEM Fitment

Even if the core ZF model is common, the BOM number dictates Hyundai’s specific integration requirements (e.g., electronic interfaces or flange types). XiaoHang Machinery Co. uses its technical database to guarantee that our parts fit and function seamlessly within Hyundai’s specifications.

Conclusion: Guarantee Hyundai Performance with XHC

XiaoHang Machinery Co. provides the verified quality and fast lead times necessary to maintain your Hyundai fleet efficiently and cost-effectively.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

CASE Construction Equipment Transmissions: Identifying ZF Models and Sourcing High-Quality Replacement Parts

Introduction: The CASE-ZF Reliability Partnership

CASE Construction has long relied on industry-leading components, including ZF transmissions and axles, for the performance and durability of its equipment (e.g., certain wheel loaders and backhoe loaders). If you service CASE machinery, understanding the specific ZF model inside is the first step to accurate parts sourcing.

This guide from XiaoHang Machinery Co. is dedicated to helping distributors servicing CASE equipment precisely identify the ZF transmission models used and source the required spares efficiently.

Section 1: Identifying ZF Models in CASE Loaders

Crucial Cross-Reference Points

Specific CASE models often utilize ZF power-shift transmissions (such as variants of the WG series). Technicians must locate the ZF nameplate on the transmission casing to retrieve the Type Designation and BOM number.

Section 2: Sourcing Strategy for CASE/ZF Spares

Mitigating the OEM Parts Premium

Servicing CASE equipment with genuine parts can be costly. XiaoHang Machinery Co. specializes in supplying verified, high-quality alternatives that perfectly match the technical specifications required by the OEM. Our 20 years of experience ensures seamless compatibility.

Conclusion: Support Your CASE Fleet with XHC Expertise

Leverage the speed of our Chinese manufacturing base and our technical precision. Contact XiaoHang Machinery Co. today for competitive pricing and expert support on ZF components used in CASE equipment.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

The ZF Brand as Your Search Gateway: How Global Customers Find the Right Aftermarket Supplier

Introduction: ZF—The Global Standard

The ZF brand name is synonymous with reliability and advanced engineering in off-highway and commercial transmissions. When international customers begin their search for replacement parts, they use “ZF” as their primary keyword. For procurement managers, finding a supplier that not only understands the ZF standard but can also deliver high-quality, cost-effective alternatives is crucial.

This guide from Tianjin XiaoHang Construction Machinery Co., Ltd., a 20-year veteran of the transmission supply industry, shows you how to optimize your search queries to quickly find reliable partners leveraging the Chinese manufacturing base.

Section 1: The Anatomy of a High-Value ZF Search

How Procurement Managers Search for Spares

Customers don’t search generically; they combine ZF with specific intent: 1. ZF + Model + Fault (e.g., ZF 4WG200 overheating). 2. ZF + Part Number + Buy. 3. ZF + OEM Name (e.g., ZF Case loader transmission).

XiaoHang Advantage: By focusing on supplying verified spares for the core ZF model lines (WG, Ecomat, BP), XiaoHang Machinery Co. directly intercepts these high-intent searches, offering instant technical solutions and reliable, competitively priced parts.

Section 2: Maximizing ROI on ZF Aftermarket Spares

Beyond the Price Tag

Our 20 years of technical expertise ensures every part we supply meets the strict performance criteria the ZF name implies. Leveraging the Chinese supply chain, we offer fast lead times and competitive pricing while guaranteeing quality.

Conclusion: Let the ZF Brand Lead You to XHC

Your search for reliable ZF parts ends with Tianjin XiaoHang Construction Machinery Co., Ltd. We are the technical authority that can guarantee both quality and supply chain speed.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |

Calculating the True ROI of Aftermarket ZF Parts: Balancing Initial Cost Savings with Long-Term Performance

Introduction: Beyond the Initial Price Tag

Procurement managers must look beyond the initial price tag when comparing genuine and aftermarket ZF parts. The true ROI (Return on Investment) lies in balancing initial cost savings against long-term reliability and performance.

This comprehensive guide from Tianjin XiaoHang Construction Machinery Co., Ltd. helps you calculate the true value of high-quality aftermarket components supplied by a verified partner.

Section 1: The Trap of “Cheap” Parts

When Low Price Equals High Risk

Substandard aftermarket parts often save 10-20% upfront but lead to repeat failure within months. This creates a hidden multiplier effect of labor costs, downtime penalties, and lost customer goodwill, annihilating any initial savings.

Section 2: The XiaoHang ROI Advantage

Calculating True Value

XiaoHang Machinery Co. focuses on verified high-quality aftermarket alternatives that: 1. Match OEM Performance: Our parts are sourced based on 20 years of field-tested durability. 2. Guarantee Cost Savings: We provide a highly competitive price point due to the efficiency of our Chinese supply chain. 3. Provide Technical Insurance: Our technical support ensures correct installation, preventing failure caused by error.

Conclusion: Maximize Your ROI with Technical Certainty

Maximize your profitability by choosing high-quality aftermarket solutions backed by XiaoHang Machinery Co.’s 20 years of technical expertise and reliable supply chain.

| Contact Detail | Information |

| Sales Representative | Tony Chang |

| Trading Entity | TIANJIN LINKWORLD TRADING CO. LTD |

| Direct Contact (Phone/WhatsApp) | +86 15822863467 |

| Expertise Provided by | Tianjin XiaoHang Construction Machinery Co., Ltd. |