By TIANJIN XIAOHANG CONSTRUCTION MACHINERY CO.,LTD – Real Solutions, Real Speed

🌍 Introduction: Global Brands, Local Problems

While CASE (CNH), John Deere, and Hyundai are global giants, the ZF transmissions and axles inside their machines are often identical to the ones we service every day in China.

However, local dealers in South America or Africa often mark up these parts by 300% or quote month-long lead times.

Tianjin Xiaohang offers a direct bridge to the source. Here is a real-world case study of how we helped a client bypass the bottleneck.

📖 Case Study: Saving a Peruvian Copper Mine

The Crisis:

- Equipment: Komatsu WA series Loader (Running a ZF Driveline).

- Failure: Catastrophic failure of the ZF Front Axle (AP-400 series) differential.

- Local Quote: “4 Weeks delivery from Europe. Price: High.”

- Cost of Downtime: $15,000 USD per day in lost production.

The Xiaohang Solution: The procurement manager found us online and contacted Tianjin Linkworld Trading.

- Cross-Reference: We identified the Komatsu part number and matched it to the Original ZF Part Number in our system.

- Inventory Check: Status: In Stock in our Tianjin warehouse.

- Action: The parts were crated and shipped via DHL Express within 6 hours.

The Result:

- Turnaround: 6 Days (from quote to delivery in Lima) vs. the 4 weeks quoted locally.

- Total Savings: Over $300,000 in prevented downtime and part cost.

I. Bridging the Gap: OEM vs. ZF Numbers

The biggest challenge for international sourcing is Part Number confusion. A CASE loader uses a CASE part number, but the part is made by ZF.

- 👉 Deep Dive: International sourcing can be tricky. Use our guide on [Identifying ZF Model Plates] to help us bridge the gap between your OEM number and the ZF number.

II. Why Choose Us Over Local Dealers?

- Price: Sourcing directly from the Authorized Dealer in China (the manufacturing base) cuts out multiple layers of middlemen.

- Expertise: We know ZF better than a generalist dealer. We know which updates and supersessions apply to your specific axle or gearbox.

💡 Summary: Experience the Difference

You don’t have to tolerate long lead times just because you run a Western machine brand.

Ready to experience this level of service? Start by sending us a photo of your needs via our [Digital Workshop].

📞 About Us: Your ZF Authorized Partner

Tianjin Xiaohang Construction Machinery Co., Ltd is your global connection to Genuine ZF parts.

- Email: 5858518@GMAIL.COM

- WhatsApp / Mobile: +86 15822863467

- Location: Tianjin, China

By TIANJIN XIAOHANG CONSTRUCTION MACHINERY CO.,LTD – Your Fast-Track to ZF Spares

📉 Introduction: The Global Supply Chain Crisis is Not Over

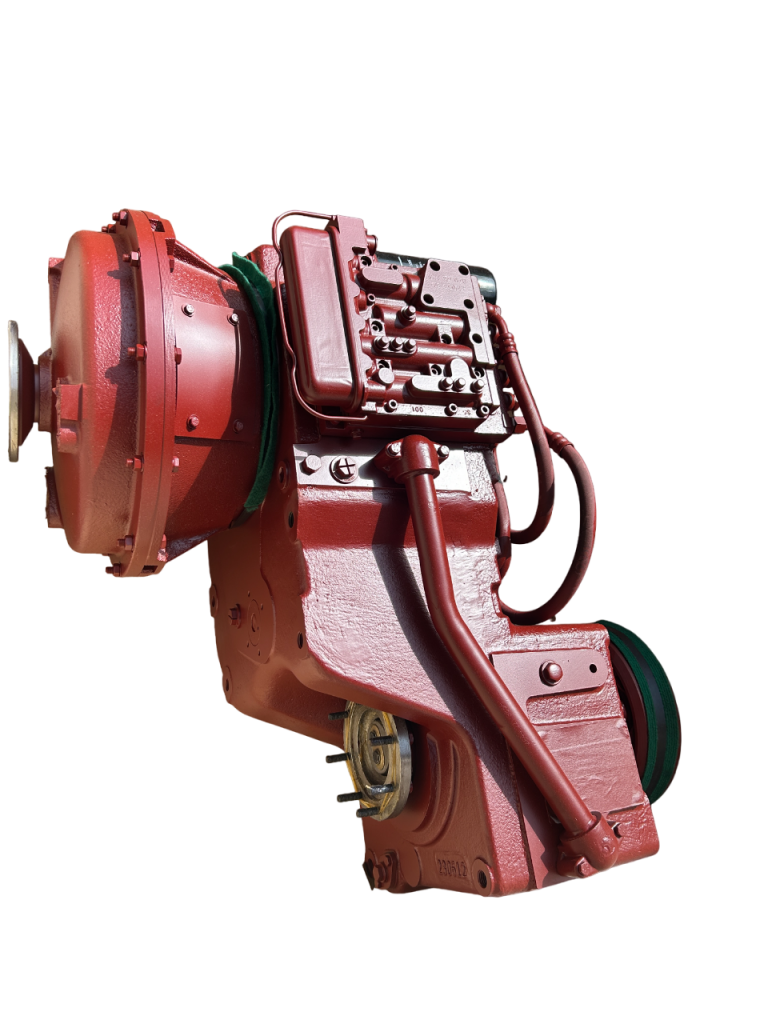

If you are a parts manager in 2025, you know the frustration well: You order a critical ZF 4WG200 overhaul kit, and the local dealer tells you, “Backordered. 12 weeks ETA.”

In the construction and mining industries, availability is the new currency. While European and North American hubs still struggle with manufacturing backlogs, the China Manufacturing Base is operating at full speed.

As a ZF Authorized Dealer with a strategic warehouse in Tianjin (China’s heavy industry hub), we offer a solution that others can’t: Immediate Dispatch.

I. The “Just-in-Time” Myth vs. Our “Deep Inventory” Reality

Many online suppliers operate on a “Just-in-Time” (JIT) model—they only order from the factory after you order from them. This adds weeks to your wait.

Tianjin Xiaohang takes a different approach:

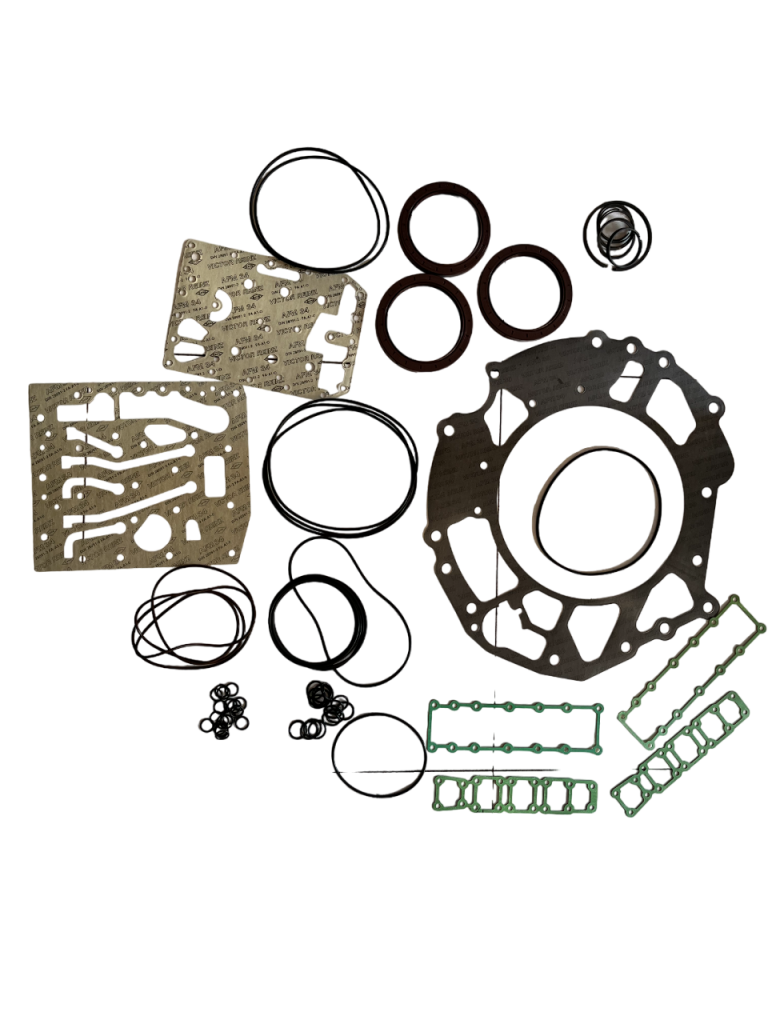

- We Stock for the Market: We analyze global usage data to stock high-mortality parts (Friction plates, Seal kits, Solenoids) for popular models like WG180, WG200, and BP230 before you need them.

- Visual Verification: If we quote “In Stock,” it means the part is physically on our shelf. We can send you a photo of the box with today’s date on it.

- 👉 Deep Dive: We stock everything from simple seals to complex electronics. Whether you have a [Common Transmission Fault] or a specific [Error Code], we have the part ready to go.

II. How We Beat the Clock: Tianjin Linkworld Trading

Having the part is only half the battle; getting it to you is the other half.

- Our Logistics Arm: Through our dedicated trading entity, Tianjin Linkworld Trading Co., Ltd, we bypass the bureaucracy.

- Speed: We don’t wait for container consolidation. For urgent orders (Machine Down), we utilize DHL / FedEx / Air Freight daily.

- Result: A customer in Brazil or Russia often receives our parts faster than ordering from a regional hub in Europe.

III. The Promise: Reliable Sourcing for Global Fleets

We don’t just supply Chinese machines. We support global fleets running Western equipment.

- 👉 Deep Dive: We supply fleets globally, supporting Western brands like [CASE, John Deere, and Hyundai] directly from China with genuine ZF parts.

💡 Summary: Time is Money

Don’t let a backorder halt your project. Check our live inventory status today. If we quote it, we have it.

📞 About Us: Your ZF Authorized Partner

Tianjin Xiaohang Construction Machinery Co., Ltd combines deep inventory with rapid global logistics.

- Email: 5858518@GMAIL.COM

- WhatsApp / Mobile: +86 15822863467

- Location: Tianjin, China

By TIANJIN XIAOHANG CONSTRUCTION MACHINERY CO.,LTD – Complete Drivetrain Solutions

🛑 Introduction: It’s Not Just About the Gearbox

When people think “ZF,” they usually think about the transmission. But for mining loaders and heavy graders (like the XCMG GR series or LiuGong 856H), the ZF Axles (AP and BP Series) bear the brunt of the load.

Search data shows that “Wet brake failure” and “Axle overheating” are top concerns for mine operators in 2025. Ignoring axle maintenance is the fastest way to turn a productive machine into a parked statue.

I. The Critical Components: Wet Multi-Disc Brakes

ZF axles use a sophisticated wet brake system housed inside the axle hub.

- The Failure Point: If the specialized axle oil isn’t changed, or if inferior friction discs are used, the braking material disintegrates.

- The Consequence: This debris travels through the axle oil, destroying the expensive planetary gears and differential.

- 👉 Deep Dive: Just like transmission clutches, axle brakes require specific friction materials. Ensure you choose [Genuine vs. “OEM Quality”: The Truth About Friction Materials] to avoid dangerous brake fade.

II. The “Wheel End” Vulnerability

The Wheel Hub (Final Drive) operates in the worst conditions—mud, sand, and water.

- The Seal Risk: The Cassette Seal (Hub Seal) is the only barrier between your gears and the dirt. Once this seal fails, water enters, and the planetary gears will grind to dust within days.

- Our Solution: We stock complete ZF Axle Overhaul Kits, including high-performance Hub Seals and Planetary Pins, ready for immediate shipment.

III. One Supplier, Full Drivetrain

Why split your orders between multiple suppliers? Tianjin Xiaohang is your one-stop source for both Transmission AND Axle parts. We verify compatibility between your gearbox output and axle input to ensure the whole drivetrain sings in harmony.

- 👉 Deep Dive: Mining environments are tough and downtime is expensive. See how we helped a South American copper mine recover from a critical axle failure in our [Case Study: Saving a Mine 3 Weeks of Downtime].

💡 Summary: Inspect Your Axles Today

Don’t wait for a grinding noise. Regular replacement of axle seals and brake discs is the cheapest insurance you can buy.

📞 About Us: Your ZF Authorized Partner

Tianjin Xiaohang Construction Machinery Co., Ltd provides complete drivetrain support—from the engine flywheel to the wheel hubs.

- Email: 5858518@GMAIL.COM

- WhatsApp / Mobile: +86 15822863467

- Location: Tianjin, China

By TIANJIN XIAOHANG CONSTRUCTION MACHINERY CO.,LTD – Making Procurement Easy

📲 Introduction: The “Lost Plate” Problem

We’ve all been there: You are under a muddy loader, the machine is down, and you need a solenoid valve or a pump. You wipe the grease off the transmission housing, only to find the ZF Identification Plate is scratched, painted over, or missing entirely.

You can’t find the part number in the manual, and your local dealer says, “No number, no part.”

In 2025, you don’t need a part number to get a quote from Tianjin Xiaohang. You just need a smartphone.

I. Visual Identification Intelligence

While AI search is popular, Human Expert Experience is irreplaceable. Our engineering team has spent 20 years staring at ZF transmissions. We recognize visual cues that manuals miss.

- The Service: Simply take a clear photo of the transmission housing, the failed component, or even the error code on the dashboard. Send it to our WhatsApp or Email.

- The Process: We analyze the shape of the connector, the casting numbers, and the mounting bolt pattern. We verify: “Is this a 12V or 24V solenoid?” or “Is this the old style pump or the superseded version?”

- 👉 Deep Dive: Our engineers don’t just look at photos; they understand the system logic. This helps us guide you on whether you should be [Repairing or Remanufacturing] the unit based on the damage we see.

II. How to Snap the Perfect Parts Photo

To get the fastest, most accurate quote from us, try to capture these three angles:

- Context: Where does the part sit on the transmission? (Zoom out).

- Details: Close-up of any engraved numbers or labels on the part itself.

- Connections: If it’s electrical, show us the plug (2-pin vs 3-pin).

III. From Photo to Dispatch

Once we identify the part from your photo, our logistics team takes over immediately.

- Cross-Reference: We match your photo to the current active ZF part number in our database.

- Speed: Because we hold deep inventory, we can usually confirm stock within minutes of receiving your image.

- 👉 Deep Dive: Once identified, we don’t waste time. Learn about our [Why “In-Stock” Matters: Navigating Global Supply Chain Delays] to see how fast we can ship.

💡 Summary: Stop Struggling with Manuals

Don’t let a missing part number stop your repair. Snap a photo, send it to +86 15822863467, and let our experts do the work.

📞 About Us: Your ZF Authorized Partner

Tianjin Xiaohang Construction Machinery Co., Ltd combines digital convenience with authorized expertise.

- Email: 5858518@GMAIL.COM

- WhatsApp / Mobile: +86 15822863467

- Location: Tianjin, China

By TIANJIN XIAOHANG CONSTRUCTION MACHINERY CO.,LTD – The “Right to Repair” Experts

🚜 Introduction: The “Right to Repair” Your Old Iron

With the rising cost of new machinery, many fleet owners are choosing to keep their trusted 15-year-old loaders (like older Komatsu WA380-3 or XCMG ZL50G) running. These machines often use legacy ZF transmissions like the 4WG180 or early 4WG200.

A common problem arises: “This part number is discontinued.” Does this mean you have to scrap the machine? Absolutely not.

I. The Challenge: Obsolescence and Updates

ZF, like all manufacturers, frequently updates its designs to improve durability.

- The Risk: Buying “New Old Stock” (NOS) from eBay that has been sitting on a shelf for 20 years. Rubber seals in these kits have likely rotted and will fail immediately.

- The Symptom: Older units are prone to overheating due to outdated cooler designs.

- 👉 Deep Dive: If your legacy unit is running hot, sometimes the issue isn’t age, but the cooling system. Check our [Troubleshooting Overheating Guide].

II. The Solution: “Supersession” (Upgrading)

This is where Tianjin Xiaohang’s technical expertise becomes your asset. We understand Interchangeability.

- What is Supersession? When ZF improves a part (e.g., a better seal material or a stronger solenoid), they issue a new part number that retrofits the old one.

- Case Example: An older WG200 uses an outdated paper gasket. We supply the modern metal/Viton upgrade kit that fits the old housing perfectly but seals 10x better.

III. We Keep the Classics Running

While major dealers focus on selling new machines, we maintain a strategic stock of parts for “Legacy” models.

- Availability: Whether it’s an early control valve or a specific torque converter shaft, we have the resources to source or identify the modern replacement.

- 👉 Deep Dive: We stock parts that others have discontinued. Our [Deep Inventory Strategy] ensures we support machines even after the OEM stops.

💡 Summary: Don’t Scrap It, Upgrade It

Your legacy equipment has years of life left. Contact Tianjin Xiaohang to find the modern, superseded ZF parts that fit your older machine perfectly.

📞 About Us: Your ZF Authorized Partner

Tianjin Xiaohang Construction Machinery Co., Ltd helps you bridge the gap between old machines and new parts.

- Email: 5858518@GMAIL.COM

- WhatsApp / Mobile: +86 15822863467

- Location: Tianjin, China

By TIANJIN XIAOHANG CONSTRUCTION MACHINERY CO.,LTD – Your Authorized Quality Guardian

🧐 Introduction: The “Grey Market” Trap

In the global parts market, procurement managers are often bombarded with terms like “OEM Quality,” “Replacement for ZF,” or “High-Quality Aftermarket.” The price difference is tempting—sometimes 30% cheaper than Genuine ZF parts.

But search trends for 2025 show a rising, painful query: “Why did my new clutch pack fail so quickly?”

As a ZF Authorized Service Dealer, Tianjin Xiaohang knows the answer lies in the microscopic details of Friction Science.

I. Not All Friction Paper is Created Equal

A generic friction plate might look identical to a Genuine ZF plate to the naked eye. However, the difference is in the engineering.

- The ZF Standard: Genuine friction material is engineered with specific porosity and friction coefficients to hold oil and dissipate heat during the critical milliseconds of gear engagement.

- The Generic Flaw: Cheap “OEM Quality” plates often glaze over at high temperatures , causing instant slippage. Once they slip, they burn, contaminating the entire hydraulic system with carbon debris.

- 👉 Deep Dive: This is also critical for axles. Poor quality seals and friction materials are the #1 cause of brake failure. Read about the importance of quality materials in our [ZF Axle Maintenance: The Overlooked Critical Service].

II. Steel Plates: The Invisible Warp

Steel reaction plates are just metal rings, right? Wrong.

- The ZF Standard: High-carbon steel, precision heat-treated for perfect flatness and resistance to warping.

- The Generic Flaw: Lower grade steel suffers from “coning” (warping) under heat. Once a plate warps, the clutch pack drags even when in neutral, boiling the oil and destroying the transmission.

III. The ROI of Genuine Parts

Buying cheap parts is like renting reliability—you have to pay again soon.

- Traceability: Every part Tianjin Xiaohang ships can be traced back to the ZF factory.

- Peace of Mind: You aren’t just buying a part; you are buying the assurance that your $200,000 loader won’t fail because of a $50 clutch plate.

- 👉 Deep Dive: Genuine parts offer better long-term ROI. See a real-world example of how quality parts saved a client in our [Case Study: Saving a South American Mine].

💡 Summary: Pay Once, Cry Once

Don’t gamble with your drivetrain. Invest in Genuine ZF parts from Tianjin Xiaohang that perform exactly as the engineers intended.

📞 About Us: Your ZF Authorized Partner

Tianjin Xiaohang Construction Machinery Co., Ltd guarantees the authenticity of every ZF part we sell. We ship globally via Tianjin Linkworld Trading Co., Ltd.

- Email: 5858518@GMAIL.COM

- WhatsApp / Mobile: +86 15822863467

- Location: Tianjin, China

By TIANJIN XIAOHANG CONSTRUCTION MACHINERY CO.,LTD – Your ZF Model Identification Specialist

🔍 Introduction: Why “Model Year” isn’t Enough

One of the most frustrating conversations in parts procurement goes like this: > Customer: “I need a transmission pump for a 2018 LiuGong loader.” > Us: “Which ZF transmission model is it?” > Customer: “I’m not sure…”

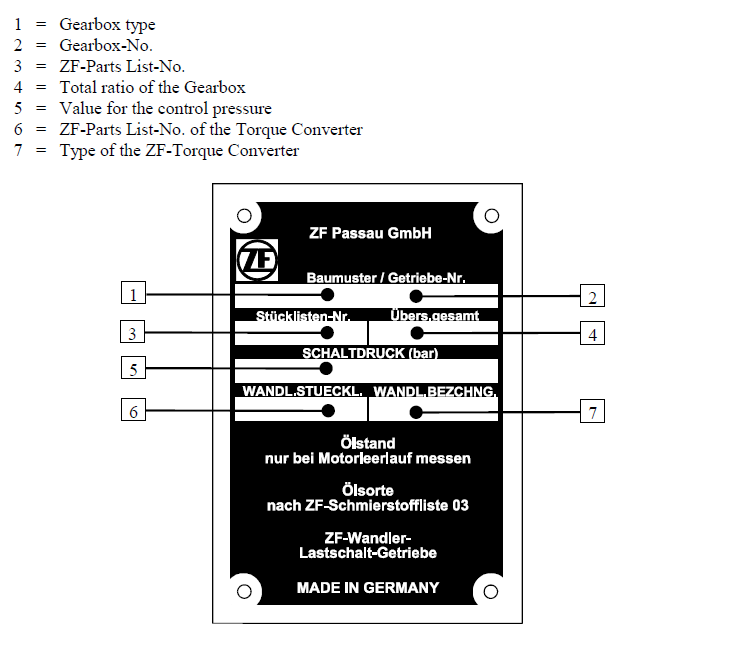

Ordering parts based solely on the machine model is dangerous. OEMs frequently change transmission specs mid-production. To guarantee the right part, you need the Data Plate.

I. Locating the ZF Identification Plate

The plate is your transmission’s ID card. It is typically a metal tag riveted to the housing.

- Location: Usually found on the side of the transmission housing, near the shift control valve or the output flange.

- The Challenge: It’s often covered in layers of grease or dried mud. Step 1 is always: Clean the area.

II. Decoding the Numbers

There are two critical numbers we need to serve you:

1. The ZF Type (Model Code)

- Example: 4WG200 vs. 6WG200.

- Why it matters: This tells us the basic architecture (4-speed vs 6-speed). However, beware: A “4WG200” in a Liugong loader might have different internal gear ratios than a “4WG200” in a XCMG grader.

2. The Serial Number / List Number (Sach-Nr)

- Example: 4644 024 015. (Usually a 10-digit number).

- Why it matters: This is the DNA. It links to the exact Bill of Materials (BOM) in the ZF database. It tells us exactly which version of the solenoid, pump, or clutch pack was installed at the factory.

- 👉 Deep Dive: ZF frequently updates part numbers. We handle the cross-referencing for you, especially for Western brands. See how we support [CASE and John Deere Fleets] by translating their numbers to ZF numbers.

III. What If the Plate is Missing?

It happens. Plates fall off or get painted over.

- Check the Chassis: Sometimes the OEM chassis plate lists the transmission serial number.

- Visual Identification: Take photos of the overall unit, the control valve, and the pump mounting.

- 👉 Deep Dive: Plate missing or unreadable? Don’t guess. You can use our [Digital Workshop Service] to order parts simply by sending us a photo.

💡 Summary: Precision Saves Time

Providing the List Number (Sach-Nr) allows Tianjin Xiaohang to verify your parts with 100% accuracy, eliminating return shipping costs and project delays.

📞 About Us: Your ZF Authorized Partner

Tianjin Xiaohang Construction Machinery Co., Ltd is your expert in identifying and sourcing hard-to-find ZF parts.

- Email: 5858518@GMAIL.COM

- WhatsApp / Mobile: +86 15822863467

- Location: Tianjin, China

By TIANJIN XIAOHANG CONSTRUCTION MACHINERY CO.,LTD – ZF Authorized Service Dealer

📉 Introduction: The Fleet Manager’s Dilemma

In the current economic climate of 2025, fleet managers are under immense pressure to cut costs. When a critical ZF transmission (e.g., in a XCMG ZL50G or SDLG 956) fails, you face a tough choice:

- Spot Repair: Replace only the broken part (Cheap, High Risk).

- Buy New: Order a brand-new unit (Expensive, Long Wait).

- Remanufacture (Overhaul): Rebuild to factory specs (The ROI Sweet Spot).

As an Authorized ZF Service Dealer, Tianjin Xiaohang provides a transparent breakdown to help you make the most profitable decision.

I. The Hidden Risks of “Spot Repair”

Replacing only a single burnt clutch pack or a failed pump might save money upfront, but in a high-hour transmission, it is often a trap.

- The Contamination Factor: When a clutch fails, it releases millions of abrasive particles into the oil. These particles hide in the torque converter and cooler. If you don’t clean the system and replace all seals, the “new” part will fail within 500 hours.

- 👉 Deep Dive: A quality rebuild depends on the materials used. Learn why authorized dealers use specific materials in our guide on [Genuine vs. “OEM Quality”: The Truth About ZF Friction Materials].

II. The “New Unit” Bottleneck

Ordering a new transmission from Europe or North America currently involves lead times of 12-16 weeks due to global supply chain constraints. Can your project afford a 3-month delay?

III. The Solution: Authorized Remanufacturing (Overhaul)

This is the preferred strategy for 80% of our global clients. By using a complete ZF Genuine Overhaul Kit, you essentially reset the clock on the transmission’s life for 40-60% of the cost of a new unit.

What a Complete Overhaul Includes:

- All Seals & Gaskets: Upgrading to Viton/modern materials.

- Friction & Steel Plates: Replacing the full stack, not just the worn ones.

- Bearings & Bushings: Ensuring shaft alignment.

- Critical Updates: Installing superseded (improved) parts.

IV. Speed is Revenue

The biggest objection to overhauling is usually “waiting for parts.”

- The Xiaohang Advantage: We don’t make you wait. We hold Deep Inventory of complete overhaul kits for WG180, WG200, and BP230 axles.

- 👉 Deep Dive: Cannot afford downtime? We offer [Immediate Dispatch for Critical Spares] to ship your overhaul kit in days, not weeks.

💡 Summary

If your machine is older than 5 years, a comprehensive Overhaul using Genuine ZF parts supplied by Tianjin Xiaohang is the mathematically superior choice for ROI.

📞 About Us: Your ZF Authorized Partner

Tianjin Xiaohang Construction Machinery Co., Ltd specializes in extending the life of your equipment with genuine ZF solutions. We ship globally via Tianjin Linkworld Trading Co., Ltd.

- Email: 5858518@GMAIL.COM

- WhatsApp / Mobile: +86 15822863467

- Location: Tianjin, China

By TIANJIN XIAOHANG CONSTRUCTION MACHINERY CO.,LTD – Masters of Transmission Electronics

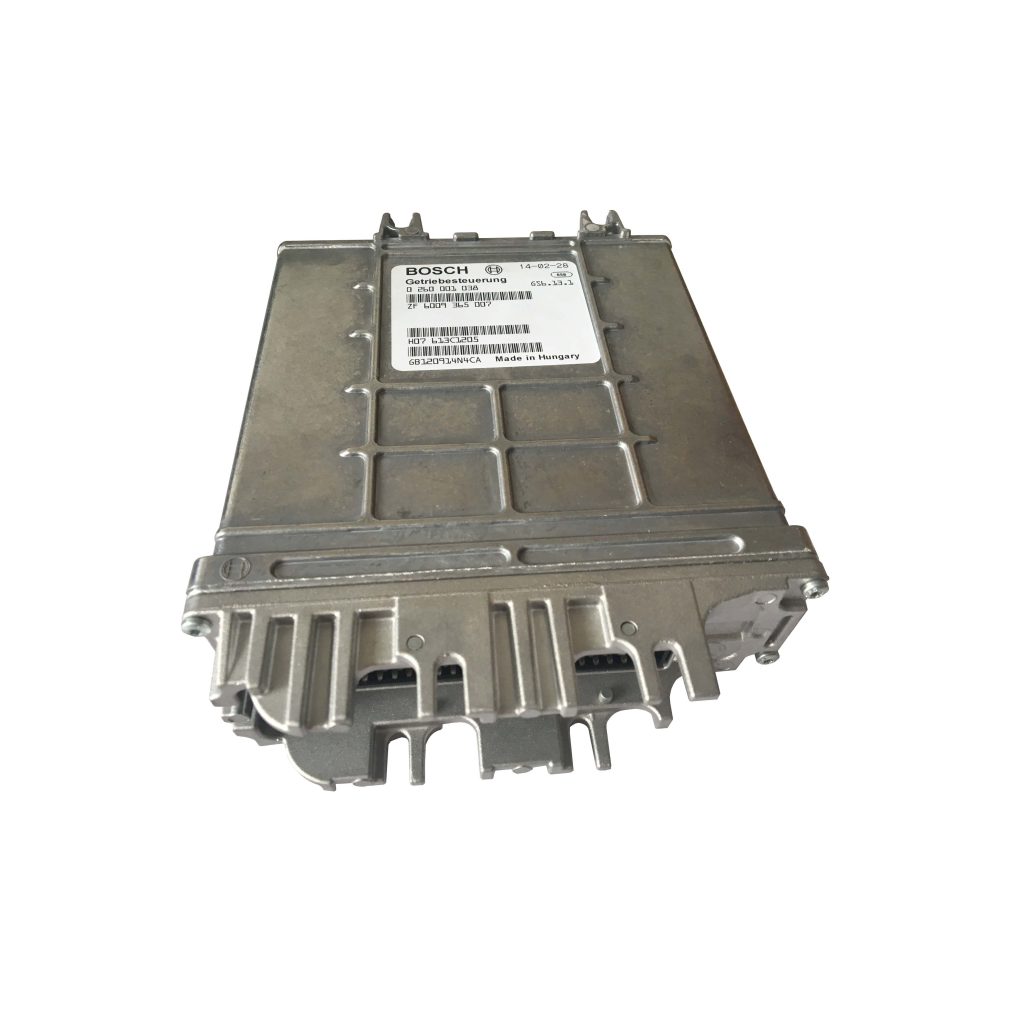

💻 Introduction: Speaking the Language of Your TCU

In the previous article, we mentioned that “Limp Mode” is a common symptom. Now, let’s get technical.

The shift from manual hydraulic valves to sophisticated Electronic Control Units (TCU / EST-37) means your mechanic needs to be part electrician. Search trends for “ZF EST-37 fault” and “ZF Ergopower solenoid resistance” are skyrocketing.

As a ZF Authorized Dealer, Tianjin Xiaohang helps you decode these signals to save thousands on unnecessary replacements.

I. The Most Common ZF Fault Categories

While codes vary by OEM (LiuGong, John Deere, and XCMG may display them differently), the underlying ZF logic remains the same.

1. Speed Sensor Plausibility (e.g., Codes related to Input/Output Speed)

- What it means: The computer sees the engine spinning but doesn’t see the transmission shaft turning accordingly.

- Common Cause: Vibration often kills the Inductive Speed Sensor located on the bell housing, or cuts the wiring harness.

- The Fix: Do not pull the transmission! Test the sensor resistance first. We stock Genuine ZF Speed Sensors for immediate air dispatch.

2. Solenoid Valve Open/Short Circuit (e.g., Codes 7x, 9x)

- What it means: The TCU tries to energize a valve (Y1, Y2, etc.) to shift gears, but the electrical circuit is broken.

- Common Cause: Internal coil failure due to thermal cycling (heating up and cooling down thousands of times).

- 👉 Internal Link: Replacing a solenoid is cheaper than a full rebuild, but you must identify the correct voltage (12V vs 24V). Read our guide on [How to Identify Your Specific ZF Model Plate] to ensure you order the right electrical parts.

3. System Pressure / Temperature Logic

- What it means: The sensors report values outside the safe range.

- Common Cause: This is often a “Mechanical issue masking as an Electrical issue.” For example, a clogged filter causes low pressure, which triggers a sensor code.

II. Troubleshooting: The “Swap Test”

Before buying parts, swap the suspect solenoid with a neighbor solenoid (if they are the same part number). If the error code moves to the new position, the solenoid is dead. If the code stays, it’s the wiring or the TCU.

III. Obsolescence Alert: Legacy Electronics

Are you dealing with an older EST-17 or early 4WG180 system? Some older electrical components are superseded.

- 👉 Internal Link: Some older machines suffer from obsolete electronics. See how we handle [Upgrading Legacy Equipment] with modern, compatible spares.

🚀 The Tianjin Xiaohang Advantage: We Verify Before We Ship

Ordering electrical parts requires precision. A visually identical solenoid might have a different resistance curve.

- Send us your Code: WhatsApp us a photo of your dashboard error.

- Send us your TCU: Send a photo of the computer label.

- We Verify: Our engineers cross-reference the exact resistance and voltage specs to ensure compatibility.

📞 About Us: Your ZF Authorized Partner

Tianjin Xiaohang Construction Machinery Co., Ltd offers expert diagnostics and genuine electrical spares for ZF transmissions. We ship globally via Tianjin Linkworld Trading Co., Ltd.

- Email: 5858518@GMAIL.COM

- WhatsApp / Mobile: +86 15822863467

- Web:www.gcwx.com

By TIANJIN XIAOHANG CONSTRUCTION MACHINERY CO.,LTD – ZF Authorized Service Dealer

🚜 Introduction: Diagnosing the Heart of Your Machine

For operators of heavy-duty loaders (like XCMG ZL50, LiuGong 856, or Komatsu WA series), the ZF Transmission (typically the 4WG200 or 6WG200 series) is the heart of the machine. When it fails, production stops.

But not all failures require a complete overhaul. As a ZF/ADVANCE Authorized Service Dealer with 20 years of field experience, Tianjin Xiaohang knows that accurate diagnosis is the key to saving money. Is it a simple sensor failure, or a melted clutch pack?

This guide covers the three most common fault categories we see in 2024/2025 and points you to the right solutions.

I. The “Limp Mode” & Dashboard Errors

Modern ZF transmissions (Ergopower series) are intelligent. They monitor input/output speeds, pressures, and temperatures. When something feels “wrong,” the Transmission Control Unit (TCU) protects the gearbox by limiting gears or neutralizing the drive.

- Symptoms: Machine is stuck in neutral, stuck in one gear, or the dashboard displays a cryptic code (e.g., “Err 74” or “D6”).

- The Likely Culprit: Often electrical, not mechanical. Speed sensors, damaged wiring harnesses, or solenoid valves are common suspects.

- 👉 Deep Dive: Modern transmissions communicate via digital codes. If you see a specific error on your dashboard, check our deep dive on [Decoding ZF Error Codes: The 2025 Guide to 4WG and Ergopower Faults].

II. Overheating: The Silent Killer

A transmission running constantly above $120^\circ\text{C}$ ($248^\circ\text{F}$) is a ticking time bomb.

- Symptoms: Dashboard temperature alarm, smell of burnt oil, or sluggish performance after 1 hour of work.

- The Likely Culprit:

- Blocked Oil Cooler: Internal clogging restricts heat exchange.

- Torque Converter Slippage: A worn lock-up clutch generates massive friction heat.

- Wrong Fluid: Using non-spec oil reduces thermal stability.

- 👉 Deep Dive: Overheating is often climate-related or maintenance-related. Learn how to prepare your machine for extremes in our [Seasonal Maintenance Guide: Preparing Your ZF Transmission for Extreme Heat and Cold].

III. Shifting Shocks & Slippage

Does your loader “bang” into gear, or does the engine rev up but the machine barely moves?

- Symptoms: Harsh engagement (Mechanical Shock) or Hesitation (Slippage).

- The Likely Culprit:

- Slippage: Usually indicates worn Friction Plates or low hydraulic pressure due to a failed seal.

- Shock: Often a sticking Proportional Solenoid Valve or incorrect TCU calibration.

- The Fix: If it’s a solenoid, we can ship a replacement kit immediately. If it’s friction wear, you need a comprehensive overhaul.

- 👉 Deep Dive: A remanufactured transmission is only as good as the parts inside. Learn the shocking truth about [Genuine vs. Counterfeit Friction Materials]. (Note: This links to Post 05)

💡 Summary: Diagnose First, Order Second

Don’t rush to buy a new transmission. Often, the fix is a specific component available in our Deep Inventory.

- Need Parts ID? If you can’t read your nameplate, use our [Digital Workshop Service] to order parts simply by sending us a photo. (Note: This links to Post 07)

📞 About Us: Your ZF Authorized Partner

Tianjin Xiaohang Construction Machinery Co., Ltd is an Authorized Service Dealer for the ZF/ADVANCE Group. Through our trading arm, Tianjin Linkworld, we provide rapid global logistics to minimize your downtime.

- Email: 5858518@GMAIL.COM

- WhatsApp / Mobile: +86 15822863467

- Location: Tianjin, China